| After-sales Service Provided: | Engineers available to service machinery overseas |

|---|---|

| Condition: | New |

| Brand Name: | DONGDING |

| Weight: | customized |

| color: | customized |

| Model Number: | DDGT |

| Place of Origin: | China (Mainland) |

| Capacity: | 20-400 T/D |

| Raw Material Moisture: | 35-65% |

| Final Moisture: | 12% (Adjustable) |

| Warantty: | One Year |

Quick Details

Specifications

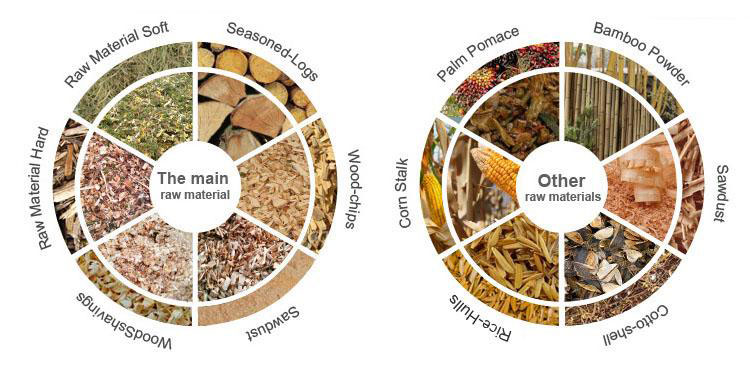

the biomass dryer can quickly dry the wet material with a moisture of 80% to a dried product with moisture less than 12%. It can be used for drying wood chips, sawdust, bark, straw, alfalfa hay, sugarcane bagasse, cassava residues, poultry manure, etc. and the final product can be applied in boiler combustion, gasification and power generation, animal feed, fertilizer, etc.

Biomass Rotary Dryer Application

* Maize, Corn, Sorghum, Wheat, Rice, Cotton straw;

* Sawdust, Wood Chips, Bark;

* Alfalfa, Napier grass, Elephant grass, Sprouted barley, Forage grass

* Coconut fiber, Coco peat, Coco coir, Palm fiber

Advantages of our Biomass Rotary Dryer

1. Multiple Heating Source. Customers can choose the heating source according their situation, we can design the customized solutions.

2. the system is optionally equipped with PLC control system and video monitoring system, which has a high degree of automation and simple operation.

3. the system is equipped with control system, with a high degree of automation and simple operation.

4. the system has a unique sealing structure, no thermal energy leakage.

5. Low investment, low operating cost, and short investment recovery time.

Company Profile

Zhengzhou Dongding Drying Equipment Co., Ltd. Is a high-tech enterprise integrating R&D design, production installation, production management, sales, after-sales service and technical consultation.

We have core technology system, which integrates the thermal combustion, dehydration, drying, molding, separation and dust removal. Scientific equipment selection and technical process optimization are adopted according to different material characteristics. Currently our equipment has been successfully applied in the coal, feed, biomass fuel, organic fertilizer processing industries. Especially the coal dryers like lignite coal dryer, coal ash dryer, raw coal rotary dryer, coal slime dryer, etc. Are well received by the customers at home and abroad.

We offer the whole biomass drying system including a heating machine, conveyor, feeding part, cylinder dryer, discharging part, and dust collector.

Biomass Rotary Dryer Application

* Maize, Corn, Sorghum, Wheat, Rice, Cotton straw;

* Sawdust, Wood Chips, Bark;

* Alfalfa, Napier grass, Elephant grass, Sprouted barley, Forage grass

* Coconut fiber, Coco peat, Coco coir, Palm fiber

Advantages of our Biomass Rotary Dryer

1. Multiple Heating Source. Customers can choose the heating source according their situation, we can design the customized solutions.

2. the system is optionally equipped with PLC control system and video monitoring system, which has a high degree of automation and simple operation.

3. the system is equipped with control system, with a high degree of automation and simple operation.

4. the system has a unique sealing structure, no thermal energy leakage.

5. Low investment, low operating cost, and short investment recovery time.

Company Profile

Zhengzhou Dongding Drying Equipment Co., Ltd. Is a high-tech enterprise integrating R&D design, production installation, production management, sales, after-sales service and technical consultation.

We have core technology system, which integrates the thermal combustion, dehydration, drying, molding, separation and dust removal. Scientific equipment selection and technical process optimization are adopted according to different material characteristics. Currently our equipment has been successfully applied in the coal, feed, biomass fuel, organic fertilizer processing industries. Especially the coal dryers like lignite coal dryer, coal ash dryer, raw coal rotary dryer, coal slime dryer, etc. Are well received by the customers at home and abroad.