| Condition: | New |

|---|---|

| Place of Origin: | China (Mainland) |

| Brand Name: | Zhenying |

| Model Number: | ZY ball mill machine |

| Type: | Ball Mill |

| CNC or Not: | Normal |

| Voltage: | 380v/220v/110v |

| Power(W): | 1850w |

| Dimension(L*W*H): | 900*1900*900(mm) |

| Weight: | 4500Kg |

| Certification: | ISO9001:2008 |

| Warranty: | 13 Months |

| After-sales Service Provided: | Engineers available to service machinery overseas |

| High Capacity: | USD2200 |

Quick Details

Specifications

| High quality zhenying brand ball mill machine

|

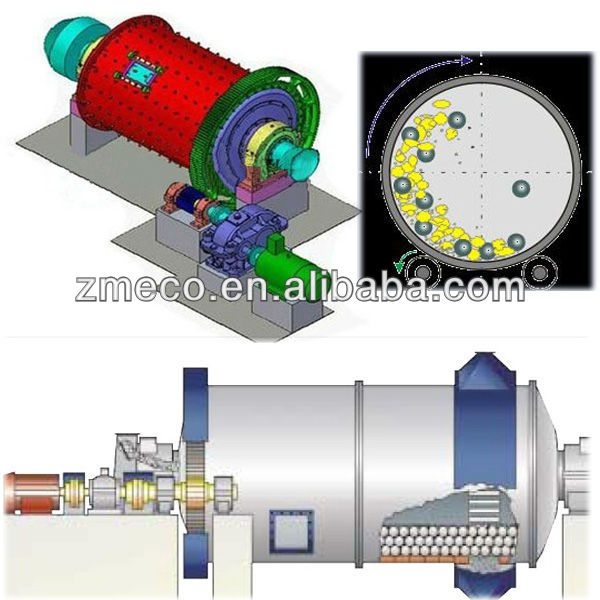

1) Efficient tool for grinding many materials into fine powder. Grind many kinds ofmine and other materials, or to select the mine.Be widely used in building material,and chemical industry. Such as glass, powder food products, create custom varnishes, make ceramic glaze, powder various chemicals. 2) Two ways of grinding: the dry way and the wet way.Ball mill can be divided into tabular type and flowing type according to different expelling mine 3) To use the ball mill machine, the material to be ground is loaded into the neoprene barrel that contains grinding media.As the barrel rotates, the material is crushed between the individual pieces of grinding media that mix and crush the product into fine powder over a period of several hours. 4) The longer the ball mill runs, the finer the powder will be.Ultimate particle size depends entirely on how hard the material you're grinding is, and the time how long the ball mill runs. |

nternal structure

|

| Application |

Balll mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grind-able materials.ing process. |

Working Principle |

| The ball mill is horizontal cylindrical rotation device, driven by brim gearwheel. There are two chambers and grid. Material goes into the first chamber through the feeding inlet. Inside the first chamber, there are stage liners and ripple liners as well as steel balls. The shell rotates so as to generate electricity, and this force brings ball to a certain height and then balls drop down by gravity, the impact is the grinding force to the material. After the primary grinding, materials go into the second chamber through segregate screen. In the second chamber, there are flat liners and steel ball, after the secondary grinding, material is discharged from the discharging. Then the whole grinding process end. |