| Brand Name: | oubaige |

|---|---|

| Thickness: | 0.2mm-350mm |

| Application: | Decorations, Heat Sink, Transportation Tools, Door & Window, Glass Wall |

| Type: | Plate |

| Grade: | 1000 series 3000 series, 5000 series |

| Model Number: | 1100, 3003,5083 |

| Place of Origin: | China (Mainland) |

| Alloy Or Not: | Is Alloy |

| Width: | 50mm-2650mm |

Quick Details

Specifications

Aluminum Sheet Production detail:

1) Alloy: 1050, 1060 1061 1070 1100 1200

2) Temper: O, H12, H14, H16, H18, H24...H112 etc.

3) Specification: Thickness: 0.2~200mm

Width: A: Cold rolling: 200--1900mm

B: Hot rolling: 800--2440mm

Length: A: Cold rolling: 500--10000mm

B: Hot rolling: 500--10000mm

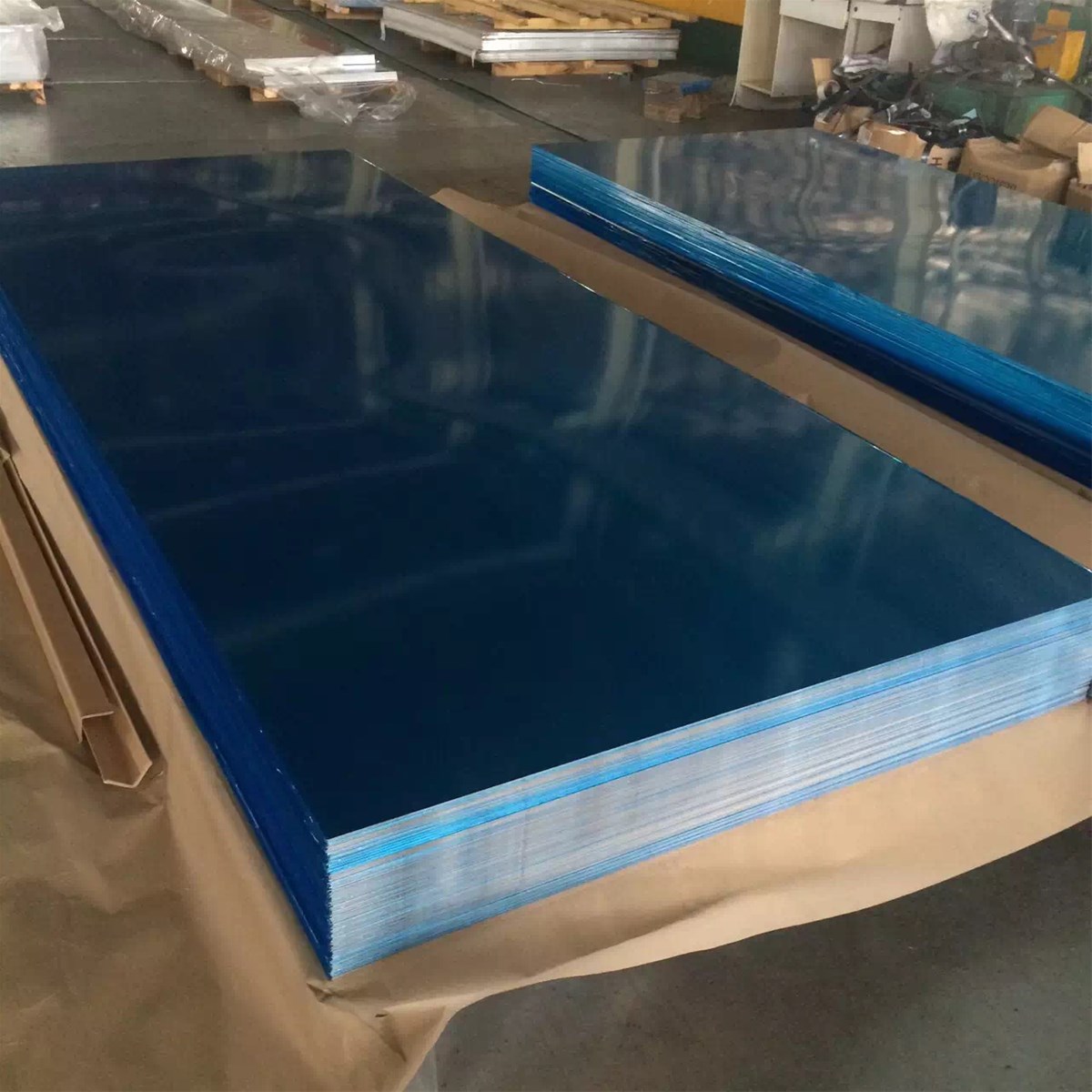

4) Surface:

1) level and smooth on the surface of the sheet;

2) the sheets' surface is clean without any corrosion, oil stains, puckering slits, scratches visible striation, rolled marks, shaken traces, cross grain or other defects;

3) no shipping spots, rolled marks, abrasive marks or dark lines;

4) no yellowish oil stains, bubbles or seams.

5) Delivery time: 15-20 days after confirming order.

6) Minimum order quantity: 1 tons per size.

7) the term of payment: T/T, L/C

8) Packing: Export standard, waterproof wooden, craft, plywood pallet, etc.

9) Application: Used in construction and light, decoration, hardware and electric appliances manufacture, automobile manufacture and other industrial and civil purposes, such as electronic capacitor, composite cooker, rice cooker, refrigerator, computer casting, telecommunication equipment, lamp shade, air-conditioner, cosmetics cover and box, air-conditioner radiator, inner container of disinfecting cabinet, ceiling board, automobile motherboard, cover board and top board, etc.

Also we would like to supply you some following more details about our part materials:

1100 Aluminum Sheet

Low strength aluminum alloy has excellent corrosion resistance and satisfactory anodizing and conversion coating finishing characteristics. It is unmatched by any other commercial aluminum alloy in workability. Readily to welding, brazing, and soldering. Machinability is poor and tends to be "gummy". Non-heat treatable. Typical applications

Include chemical storage, processing equipment, kitchen utensils, and general sheet metal work.

3003 Aluminum Sheet

Approx. 20% higher strength than the 1100 series, but retaining an excellent workability rating. May show some slight discoloration when anodized, but reacts well to mechanical and organic finishings. 3003 is easily welded and brazed, but solder is limited to the torch method. like 1100, tends to be "gummy" when machined. Non-heat treatable. Typical applications include food and chemical equipment, appliance components, truck and trailer roofing, heat exchangers, and lawn furniture components.

5083 Aluminum Sheet

with excellent corrosion resistance and weldability, together with high strength, this alloy was designed for welded structures requiring maximum joint strength and efficiency. Can be anodized for increased corrosion resistance, but does not lend itself to decorative applications. Not meant to be a machining alloy, but can be machined fairly well with proper preparations. Because of its relatively high magnesium content, the workability rating would only be fair. Non-heat treatable. Typical applications include large marine craft, containers, railroad cars, structurals and elevator cars.

1) Alloy: 1050, 1060 1061 1070 1100 1200

2) Temper: O, H12, H14, H16, H18, H24...H112 etc.

3) Specification: Thickness: 0.2~200mm

Width: A: Cold rolling: 200--1900mm

B: Hot rolling: 800--2440mm

Length: A: Cold rolling: 500--10000mm

B: Hot rolling: 500--10000mm

4) Surface:

1) level and smooth on the surface of the sheet;

2) the sheets' surface is clean without any corrosion, oil stains, puckering slits, scratches visible striation, rolled marks, shaken traces, cross grain or other defects;

3) no shipping spots, rolled marks, abrasive marks or dark lines;

4) no yellowish oil stains, bubbles or seams.

5) Delivery time: 15-20 days after confirming order.

6) Minimum order quantity: 1 tons per size.

7) the term of payment: T/T, L/C

8) Packing: Export standard, waterproof wooden, craft, plywood pallet, etc.

9) Application: Used in construction and light, decoration, hardware and electric appliances manufacture, automobile manufacture and other industrial and civil purposes, such as electronic capacitor, composite cooker, rice cooker, refrigerator, computer casting, telecommunication equipment, lamp shade, air-conditioner, cosmetics cover and box, air-conditioner radiator, inner container of disinfecting cabinet, ceiling board, automobile motherboard, cover board and top board, etc.

Also we would like to supply you some following more details about our part materials:

1100 Aluminum Sheet

Low strength aluminum alloy has excellent corrosion resistance and satisfactory anodizing and conversion coating finishing characteristics. It is unmatched by any other commercial aluminum alloy in workability. Readily to welding, brazing, and soldering. Machinability is poor and tends to be "gummy". Non-heat treatable. Typical applications

Include chemical storage, processing equipment, kitchen utensils, and general sheet metal work.

3003 Aluminum Sheet

Approx. 20% higher strength than the 1100 series, but retaining an excellent workability rating. May show some slight discoloration when anodized, but reacts well to mechanical and organic finishings. 3003 is easily welded and brazed, but solder is limited to the torch method. like 1100, tends to be "gummy" when machined. Non-heat treatable. Typical applications include food and chemical equipment, appliance components, truck and trailer roofing, heat exchangers, and lawn furniture components.

5083 Aluminum Sheet

with excellent corrosion resistance and weldability, together with high strength, this alloy was designed for welded structures requiring maximum joint strength and efficiency. Can be anodized for increased corrosion resistance, but does not lend itself to decorative applications. Not meant to be a machining alloy, but can be machined fairly well with proper preparations. Because of its relatively high magnesium content, the workability rating would only be fair. Non-heat treatable. Typical applications include large marine craft, containers, railroad cars, structurals and elevator cars.