| Use: | Warehouse Rack |

|---|---|

| Feature: | Corrosion Protection |

| Material: | Steel |

| Type: | Selective Pallet Rack |

| Brand Name: | 76.2 Pitch Australian Standard Heavy Duty Pallet Rack |

Quick Details

Specifications

76.2 Pitch Australian Standard Heavy Duty Pallet Rack

76.2 pitch pallet rack is the most popular and versatile racking in the industry. It offers the best solutions for warehouses with palletized products and a wide variety of goods. 76.2 pitch pallet racks is very popular in the markets of Australia and New Zealand.

Features

Individual access to all pallets to full height of warehouse

Easy beam adjustment accommodates variable pallet heights

Simple stock rotation achieved

Compatible with many handling equipment types

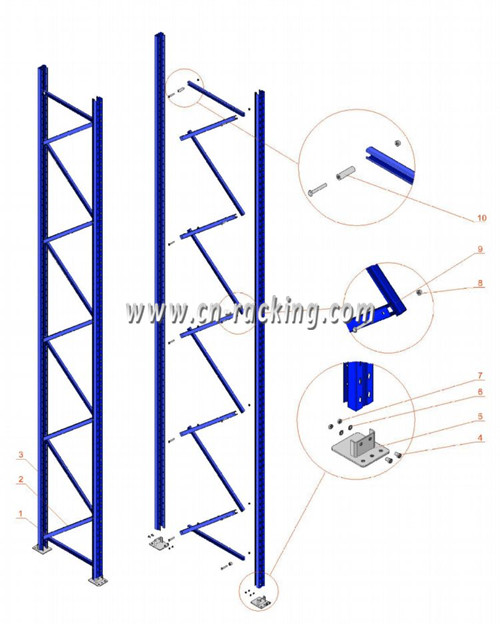

1.Horizontal Bracing

2.Diagonal Bracing

3.Upright Column

4.Bolt for Base-Column Connect

5.Base Plate

6.Bolt Washer

7.Nut Cap

8.Nut Cap for Bracing Connect

9.Bolt for Bracing Connect

10.Sleeve

Beam

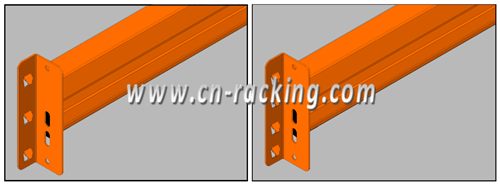

HOT Racking beams consist of hollow profiles with beam end connectors welded to each end to connect with the uprights. Beam end connectors are available with 3 or 4 pins. Beams have an electrostatic epoxy powder coated (standard finish orange RAL 2004). Safety pins are also available to prevent the beams from unhooking.

Beam connector

According to section size of beam, 3 or 4 holes hook can be chose to satisfy different capacity needs. Safety lock has been collocated on the connection, locking the beams firmly. Safety lock has been pre-installed at the factory which increases installation work efficiency and avoid safety issues without safety lock.

during the operation, due to the beam impacting by forklift, as long as safety lock does not popular, the beam would be still stuck on the upright. so security risks could be avoided.

76.2 pitch pallet rack is the most popular and versatile racking in the industry. It offers the best solutions for warehouses with palletized products and a wide variety of goods. 76.2 pitch pallet racks is very popular in the markets of Australia and New Zealand.

Features

Individual access to all pallets to full height of warehouse

Easy beam adjustment accommodates variable pallet heights

Simple stock rotation achieved

Compatible with many handling equipment types

1.Horizontal Bracing

2.Diagonal Bracing

3.Upright Column

4.Bolt for Base-Column Connect

5.Base Plate

6.Bolt Washer

7.Nut Cap

8.Nut Cap for Bracing Connect

9.Bolt for Bracing Connect

10.Sleeve

Beam

HOT Racking beams consist of hollow profiles with beam end connectors welded to each end to connect with the uprights. Beam end connectors are available with 3 or 4 pins. Beams have an electrostatic epoxy powder coated (standard finish orange RAL 2004). Safety pins are also available to prevent the beams from unhooking.

Beam connector

According to section size of beam, 3 or 4 holes hook can be chose to satisfy different capacity needs. Safety lock has been collocated on the connection, locking the beams firmly. Safety lock has been pre-installed at the factory which increases installation work efficiency and avoid safety issues without safety lock.

during the operation, due to the beam impacting by forklift, as long as safety lock does not popular, the beam would be still stuck on the upright. so security risks could be avoided.