| After-sales Service Provided: | Engineers available to service machinery overseas |

|---|---|

| Brand Name: | xinheng |

| Automatic Grade: | Automatic |

| Type: | Horizontal |

| Condition: | New |

| Automatic Grade: | Automatic |

| Type: | Horizontal |

| Condition: | New |

| CNC or Not: | CNC |

| Blanks weight: | 30g |

| Productivity: | 70n/min |

| MotorPower: | 4kw |

| Frequency furnace power: | 50kw |

| Machine weight: | 2500kg |

| Machine size: | 2150X1100X1100mm |

Quick Details

Specifications

BRASS VALVE PRODUCTION LINE:

the complete brass valve production line is composed of Brass rod making machines, Automatic brass forging machines, CNC lathe machines and assembly line equipment. We can customize the production line for different requirements, the productivity will be improved by the full automatic feeding device.

PRODUCTION: the production line can be designed for brass valve body, air-conditioning nuts, communication valve hand wheel, plumbing joints, copper hex nuts, copper nuts, wire, outer wire, wire, spool, Variants, joints, joint caps, single joints, forging nuts, air-conditioning cut-off valve, spool, water pressure cap, valves, and caps, plugs and so on.

ADVANTAGES of BRASS VALVE PRODUCTION LINE: High level of automation: it can realize whole-process automation.

High production efficiency: the work efficiency is five times as high as the normal vertical machine, and the productivity is 30 to 100 workpieces per minute (depending on the size of the product). Low Labor Cost: One person operate several machines, compared with the traditional manufacturing process can save 6-7 labors.

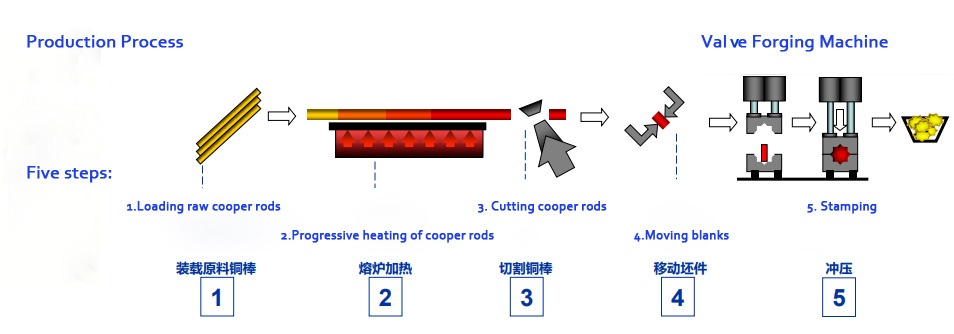

Step 1: the brass rod making machines process copper rod from scrap copper material.

Step 2: the automatic valve hot forging machine is a high efficient automatic machine which produce variety shapes of semi-finished product(valve blanks).

Step 3: Finally turning the valve blanks into finish products.

PARAMETER:

PRODUCTION: the production line can be designed for brass valve body, air-conditioning nuts, communication valve hand wheel, plumbing joints, copper hex nuts, copper nuts, wire, outer wire, wire, spool, Variants, joints, joint caps, single joints, forging nuts, air-conditioning cut-off valve, spool, water pressure cap, valves, and caps, plugs and so on.

ADVANTAGES of BRASS VALVE PRODUCTION LINE: High level of automation: it can realize whole-process automation.

High production efficiency: the work efficiency is five times as high as the normal vertical machine, and the productivity is 30 to 100 workpieces per minute (depending on the size of the product). Low Labor Cost: One person operate several machines, compared with the traditional manufacturing process can save 6-7 labors.

Step 1: the brass rod making machines process copper rod from scrap copper material.

Step 2: the automatic valve hot forging machine is a high efficient automatic machine which produce variety shapes of semi-finished product(valve blanks).

Step 3: Finally turning the valve blanks into finish products.

PARAMETER:

| Model | Blanks weight (g) | Productivity (n/min) | MotorPower (KW) | Frequency furnace power(KW) | Machine weight (KG) | Machine size L*W*H (mm) |

| ZW-TA06 | 30 | 70 | 4 | 50 | 2500 | 2150X1100X1100 |

| ZW-TA08 | 50 | 70 | 7.5 | 60 | 5000 | 4200X1500X1450 |

| ZW-TA10 | 100 | 70 | 15 | 80 | 8000 | 4900X1850X1820 |

| ZW-TA12 | 120 | 70 | 18.5 | 100 | 10000 | 5000X1900X1800 |

| ZW-TA16 | 160 | 65 | 22 | 120 | 12000 | 5600X1900X1950 |

| ZW-TA20 | 200 | 60 | 30 | 150 | 15000 | 5800X1950X1900 |

| ZW-TA30 | 250 | 60 | 30 | 200 | 18000 | 5800X2000X1900 |

Anyang Xinheng Machine Tool Co. Ltd. Is a professional machine tool manufacturer since 1946. Our factory covers an area of more than 30000 squares meters, equipped with our updated manufacturing facilities. We have LATHE, CNC LATHE, PIPE THREAD LATHE, SPHERE TURNING LATHE etc. We have attained ISO9001:2000 International Quality Control System Certification. Our products are sold both at home and abroad, and they are very popular around the world. Welcome to contact us!

Our service:

Free replacing parts available in the warranty period.

Cost price replacing parts available beyond the warranty period.

Quick action and reply for the technical questions at any time in the whole life of the machine.

Overseas after service center available in some region.

Engineer overseas service available on the requirement of customer(relative cost born by customer).

Free design drawing, free installation, free debugging, Cheap accessories.