| After-sales Service Provided: | Engineers available to service machinery overseas |

|---|---|

| Brand Name: | xinheng |

| Automatic Grade: | Automatic |

| Type: | Horizontal |

| Condition: | New |

| Place of Origin: | China (Mainland) |

| After-sales Service Provided: | Engineers available to service machinery overseas |

| Automatic Grade: | Automatic |

| Type: | Horizontal |

| Condition: | New |

| Certification: | ISO9001 |

| Weight: | 5000KG |

Quick Details

Specifications

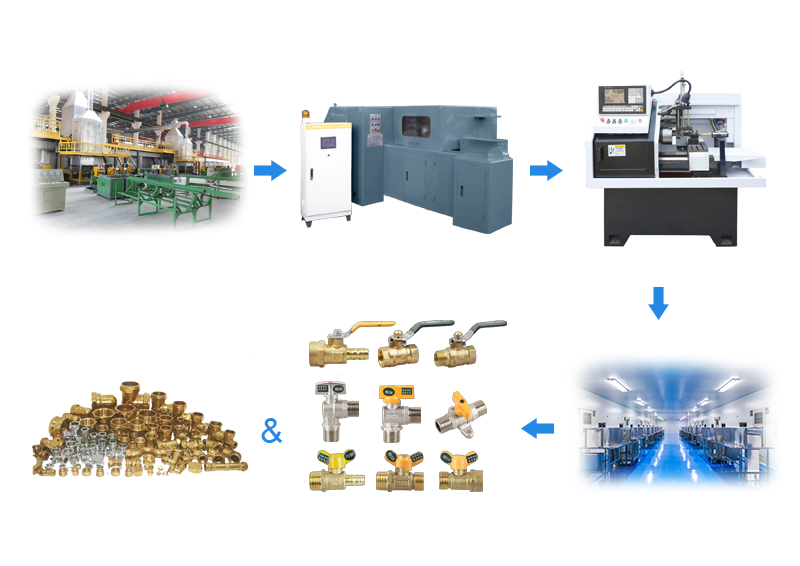

the complete production line consists of brass rod making machines, brass forging machines, CNC lathes and assembly line. It can produce the valves from scrap cooper material. The brass making machines including melting furnace, temperature keeping furnace, automatic cutting machine and so on. The manufacturing process are as follows:

Step 1: the brass rod making machines process copper rod from scrap copper material.

Step 2: the automatic valve hot forging machine is a high efficient automatic machine which produce variety shapes of semi-finished product(valve blanks).

Step 3: Finally turning the valve blanks into finish products.

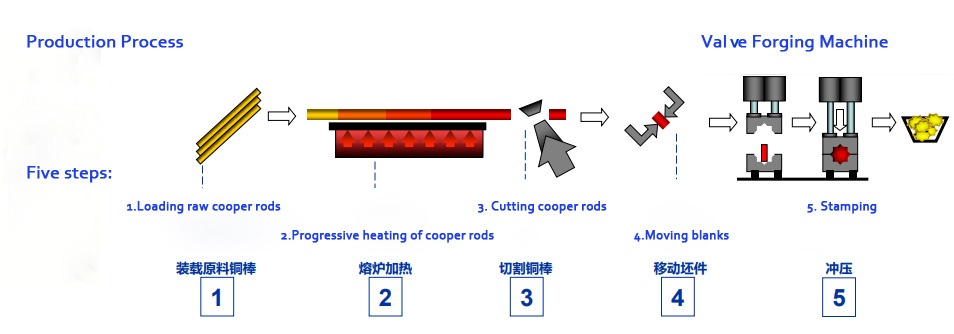

the PRODUCTION PROCESS: 1. BRASS ROD HORIZONTAL CONTINUOUS CASTING PRODUCTION PROCESS IS AS FOLLOWS:Raw materialMelting furnaceHolding furnaceTractionAutomatic cutting machineHydraulic drawing machinePeelingFinished product brass rod.

2. BRASS VALVE BLANK FORGING PROCESS:

3. CNC LATHE MACHINING PARAMETER:

APPLICATION:

Step 1: the brass rod making machines process copper rod from scrap copper material.

Step 2: the automatic valve hot forging machine is a high efficient automatic machine which produce variety shapes of semi-finished product(valve blanks).

Step 3: Finally turning the valve blanks into finish products.

the PRODUCTION PROCESS: 1. BRASS ROD HORIZONTAL CONTINUOUS CASTING PRODUCTION PROCESS IS AS FOLLOWS:Raw materialMelting furnaceHolding furnaceTractionAutomatic cutting machineHydraulic drawing machinePeelingFinished product brass rod.

2. BRASS VALVE BLANK FORGING PROCESS:

3. CNC LATHE MACHINING PARAMETER:

| Model | Blanks weight (g) | Productivity (n/min) | MotorPower (KW) | Frequency furnace power(KW) | Machine weight (KG) | Machine size L*W*H (mm) |

| ZW-TA06 | 30 | 70 | 4 | 50 | 2500 | 2150X1100X1100 |

| ZW-TA08 | 50 | 70 | 7.5 | 60 | 5000 | 4200X1500X1450 |

| ZW-TA10 | 100 | 70 | 15 | 80 | 8000 | 4900X1850X1820 |

| ZW-TA12 | 120 | 70 | 18.5 | 100 | 10000 | 5000X1900X1800 |

| ZW-TA16 | 160 | 65 | 22 | 120 | 12000 | 5600X1900X1950 |

| ZW-TA20 | 200 | 60 | 30 | 150 | 15000 | 5800X1950X1900 |

| ZW-TA30 | 250 | 60 | 30 | 200 | 18000 | 5800X2000X1900 |

APPLICATION: