| After-sales Service Provided: | Engineers available to service machinery overseas |

|---|---|

| Brand Name: | XINHENG |

| Automatic Grade: | Automatic |

| Type: | Horizontal |

| Condition: | New |

| Certification: | ISO9001 |

| Voltage: | 220V |

| Place of Origin: | China (Mainland) |

| CNC or Not: | CNC |

| port: | shanghai |

| color: | blue |

| warranty: | 12 months |

| packing: | standard wooden box |

Quick Details

Specifications

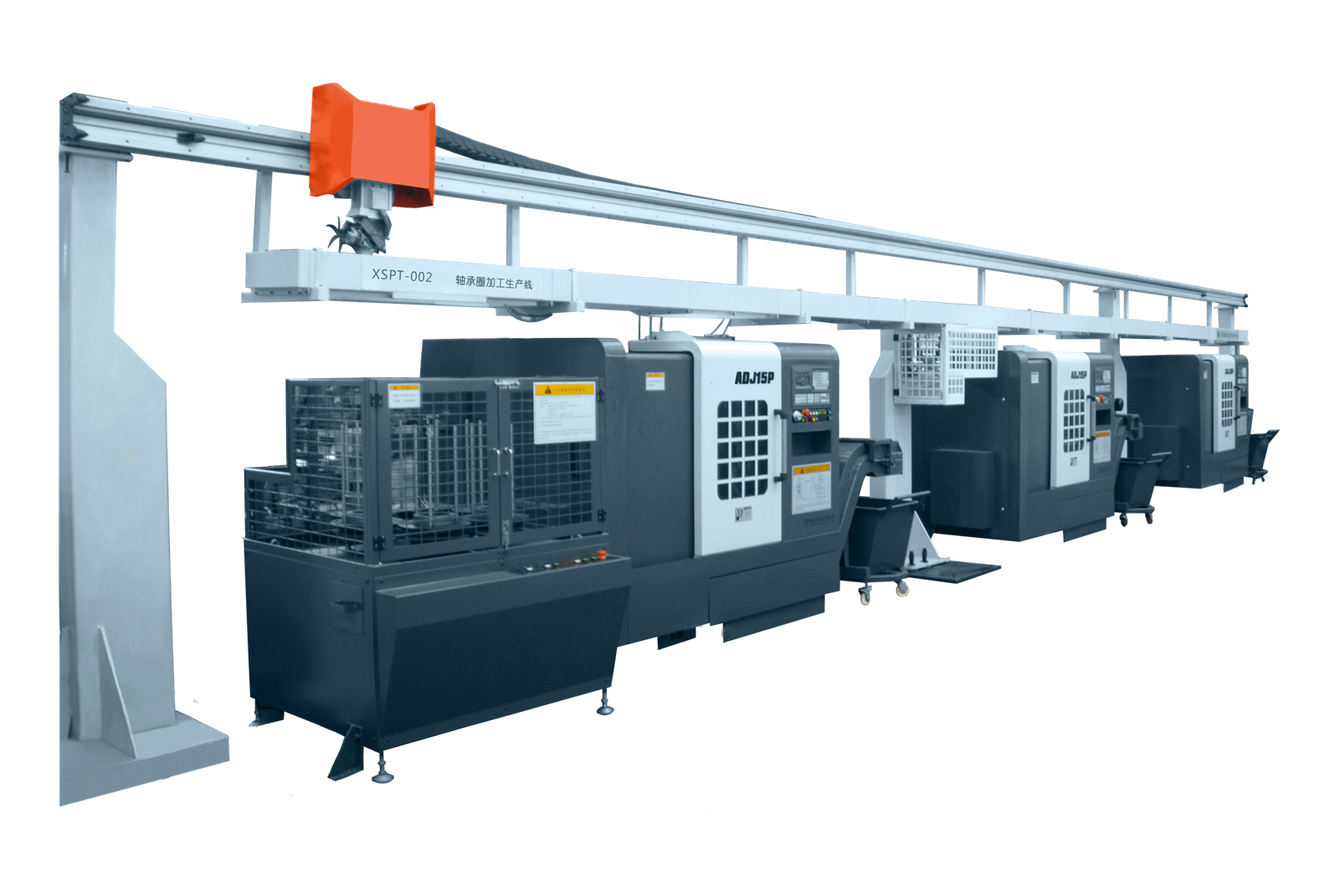

AUTOMATIC BEARING RING PRODUCTION LINE:XSPT-002 bearing ring automatic line is composed of three ADJ15P CNC lathes and a set of SMT20 Manipulator automatic feeding device.

the automatic line to grab the workpiece weight 7Kg.

Outer diameter: 100mm-200mm

the width of disk type parts: 14mm-70mm.

Designed according to user-specific requirements.

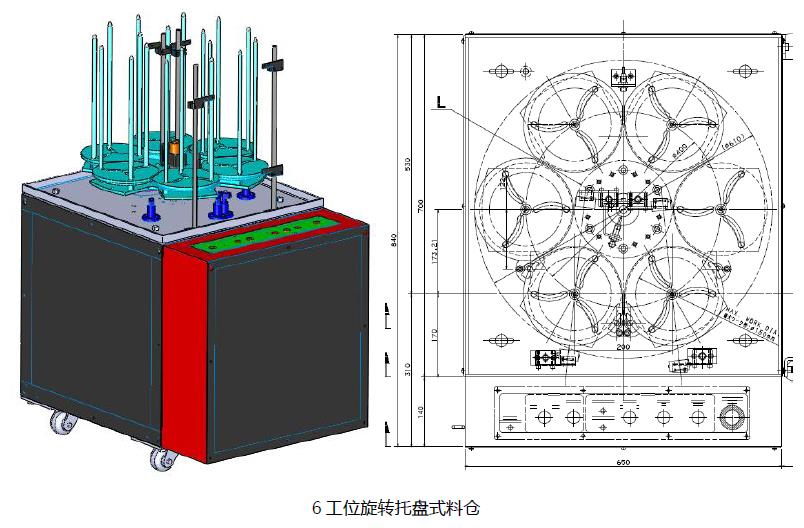

SIX-STATION ROTARY TRAY SILOS:the feeding device of the automatic line is composed by the 6 Station pallet type rotary silos, and the silo is controlled by the sensor induction signal. It can control the feeding position and the stroke of each action.

Silo specifications: 6 stations.

Delivery parts diameter: 30 ~ 230;

Each station stack height: 400mm.

Each tray carry weight: 35kg.

the automatic line to grab the workpiece weight 7Kg.

Outer diameter: 100mm-200mm

the width of disk type parts: 14mm-70mm.

Designed according to user-specific requirements.

| Workpiece | Bearing out ring(No. CG-GAC110S/K.01-LG1) |

| Annual output estimation | 12 months26 days20 hours3600 seconds0.85 Utilization rate/85 seconds(Automatic line cycle time)= 224640 pieces. |

SIX-STATION ROTARY TRAY SILOS:the feeding device of the automatic line is composed by the 6 Station pallet type rotary silos, and the silo is controlled by the sensor induction signal. It can control the feeding position and the stroke of each action.

Silo specifications: 6 stations.

Delivery parts diameter: 30 ~ 230;

Each station stack height: 400mm.

Each tray carry weight: 35kg.