| Type: | Other Type |

|---|---|

| Seals Type: | wooden case |

| Outside Diameter: | 0-0 mm |

| Bore Size: | 0-0 mm |

| Brand Name: | xinheng |

| Type: | horizontal |

| After-sales Service Provided: | Engineers available to service machinery overseas |

| Automatic Grade: | Automatic |

| Condition: | New |

| Certification: | ISO9001 |

| Voltage: | 220V |

Quick Details

Specifications

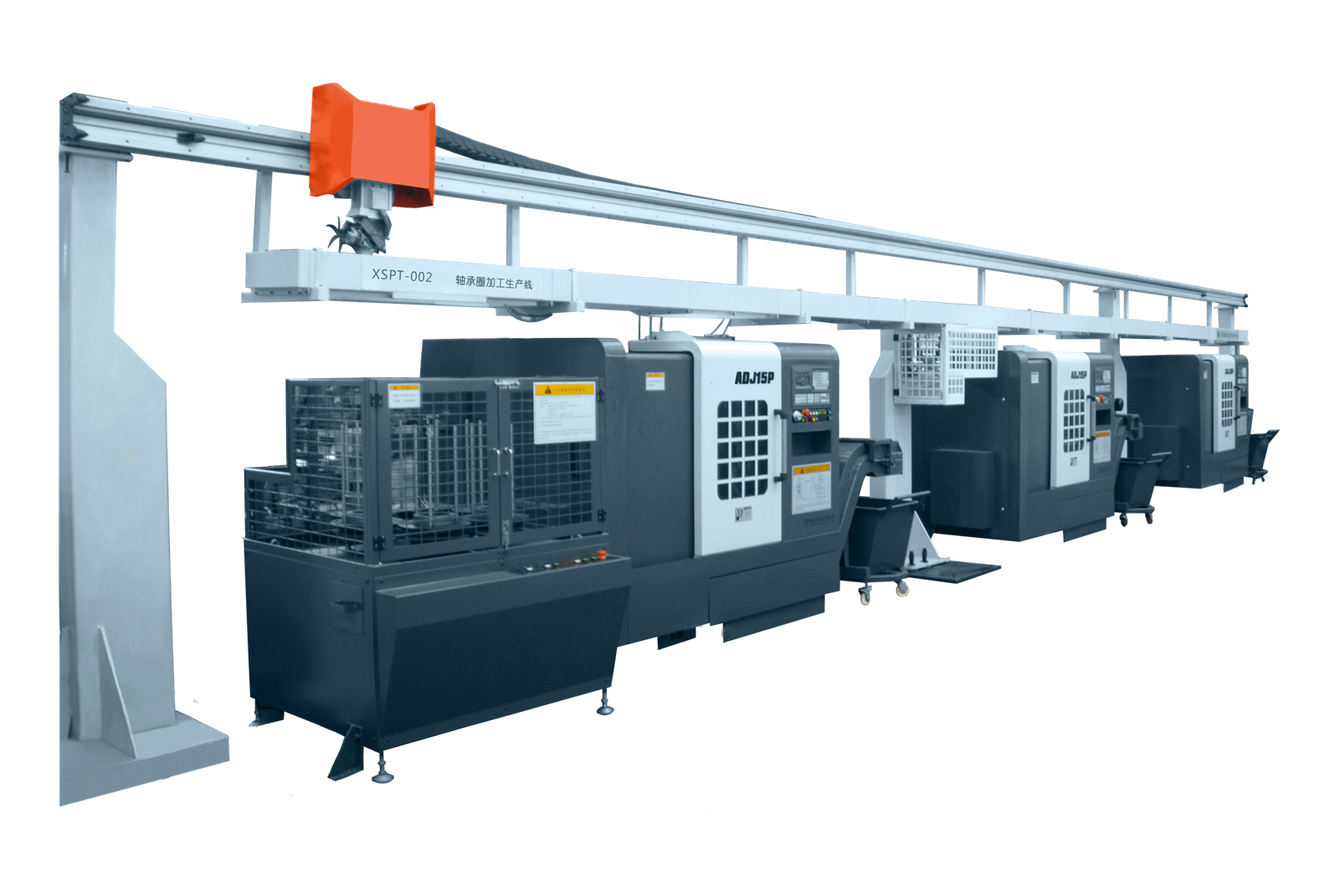

AUTOMATIC BEARING RING PRODUCTION LINE:XSPT-002 bearing ring automatic line is composed of three ADJ15P CNC lathes and a set of SMT20 Manipulator automatic feeding device.

the automatic line to grab the workpiece weight 7Kg.

Outer diameter: 100mm-200mm

the width of disk type parts: 14mm-70mm.

Designed according to user-specific requirements.

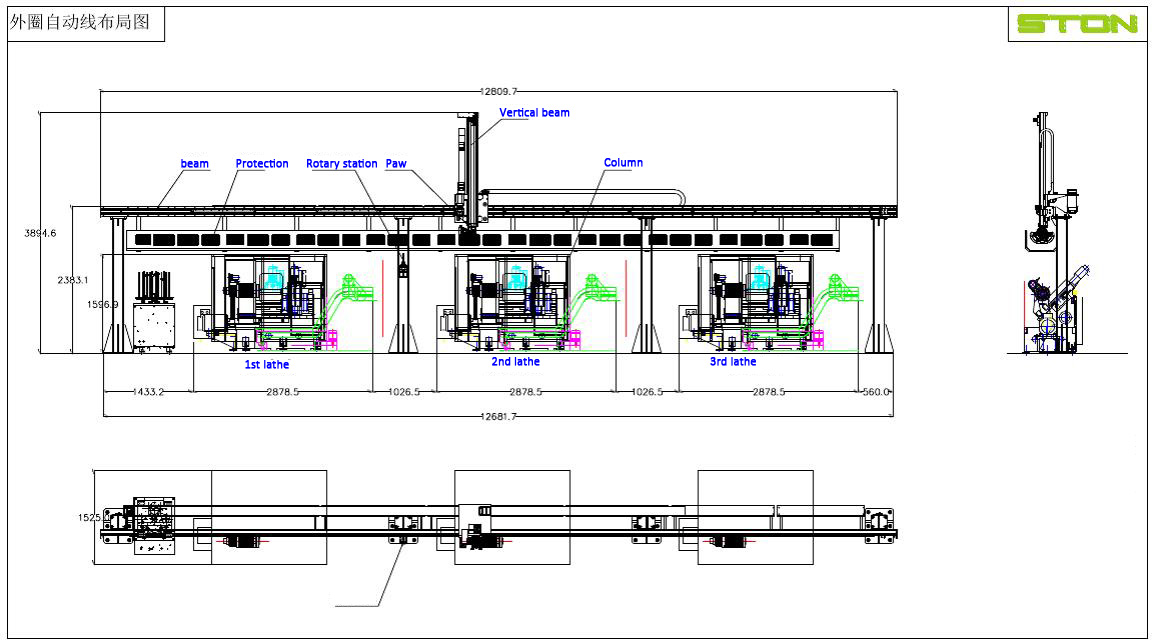

LAYOUT of the BEARING RING LATHES:

SIX-STATION ROTARY TRAY SILOS:the feeding device of the automatic line is composed by the 6 Station pallet type rotary silos, and the silo is controlled by the sensor induction signal. It can control the feeding position and the stroke of each action.

Silo specifications: 6 stations.

Delivery parts diameter: 30 ~ 230;

Each station stack height: 400mm.

Each tray carry weight: 35kg.

the automatic line to grab the workpiece weight 7Kg.

Outer diameter: 100mm-200mm

the width of disk type parts: 14mm-70mm.

Designed according to user-specific requirements.

| Workpiece | Bearing out ring(No. CG-GAC110S/K.01-LG1) |

| Annual output estimation | 12 months26 days20 hours3600 seconds0.85 Utilization rate/85 seconds(Automatic line cycle time)= 224640 pieces. |

LAYOUT of the BEARING RING LATHES:

SIX-STATION ROTARY TRAY SILOS:the feeding device of the automatic line is composed by the 6 Station pallet type rotary silos, and the silo is controlled by the sensor induction signal. It can control the feeding position and the stroke of each action.

Silo specifications: 6 stations.

Delivery parts diameter: 30 ~ 230;

Each station stack height: 400mm.

Each tray carry weight: 35kg.

Anyang Xinheng Machine Tool Co. Ltd. Is a professional machine tool manufacturer since 1946. Our factory covers an area of more than 30000 squares meters, equipped with our updated manufacturing facilities. We have LATHE, CNC LATHE, PIPE THREAD LATHE, SPHERE TURNING LATHE etc. We have attained ISO9001:2000 International Quality Control System Certification. Our products are sold both at home and abroad, and they are very popular around the world. Welcome to contact us!

Our service:

Free replacing parts available in the warranty period.

Cost price replacing parts available beyond the warranty period.

Quick action and reply for the technical questions at any time in the whole life of the machine.

Overseas after service center available in some region.

Engineer overseas service available on the requirement of customer(relative cost born by customer).

Free design drawing, free installation, free debugging, Cheap accessories.