| After-sales Service Provided: | Engineers available to service machinery overseas |

|---|---|

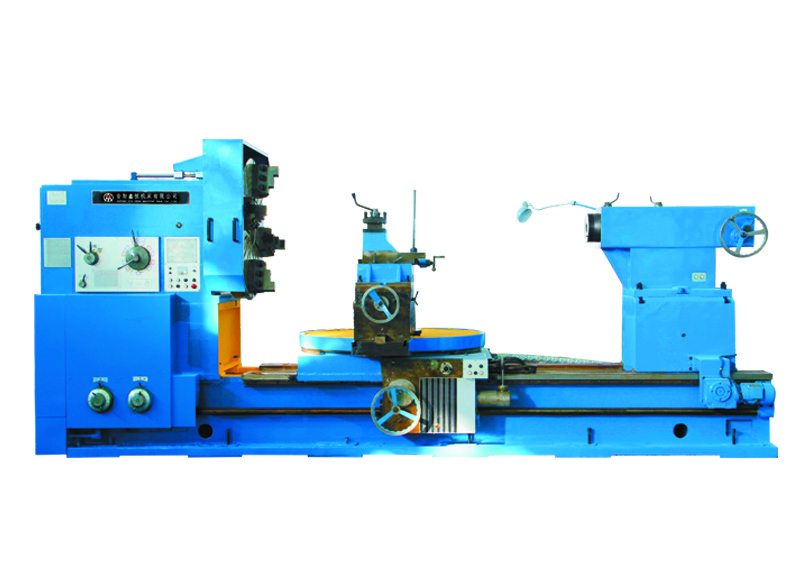

| Brand Name: | XINHENG |

| Automatic Grade: | Automatic |

| Type: | Horizontal |

| Condition: | New |

| Certification: | ISO9001 |

| Weight: | 12000KG |

| Dimension(L*W*H): | 4700*2500*2000mm |

| Power(W): | 22kw |

| Voltage: | 220v |

| Model Number: | C6595 |

| Place of Origin: | China (Mainland) |

| CNC or Not: | CNC |

| Max. Dia. of spherical: | 900mm |

| Min. Dia. of spherical: | 260mm |

| Dia. of spindle hole: | 130mm |

| Taper of hole of spindle: | 140mm |

| No. of spindle speeds: | 21 |

| Range of spindle speeds: | 3.15-315r/min |

| Spindle reverse speeds: | 3.5-291r/min |

| Swivel angle of toolpost: | 90 |

| warranty: | 12 months |

Quick Details

Specifications

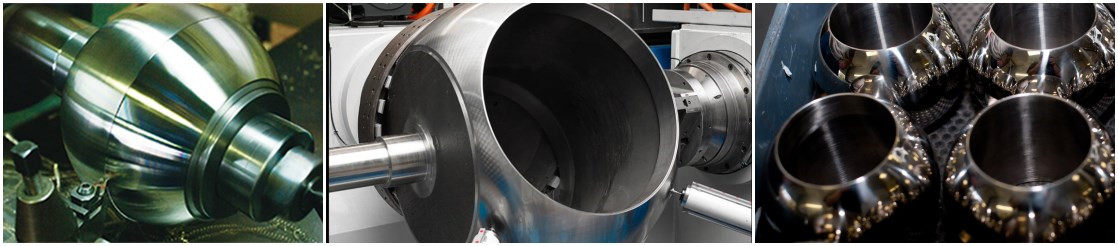

Spherical turning lathe, is also called ball turning lathe, external spherical surface turning lathe or globe lathe machine. Spherical turning lathe is mainly used for spherical outside surface, inner surface and the ball on shafts machining. The process range of spherical diameter is 550mm - 1800mm.Our company developed the spherical lathe according to the market demand, mainly used for the outer ball of the ball rough machining, finish grinding. It also can be used as a common lathe, such as turning cylindrical, bore, end and so on.

in China, we are the most professional spherical turning lathes manufacturer. Our factory has the best technical support team. The spherical surface turning lathe will be customized according to differernt requirements.

TECHNICAL PARAMETERS:

FEATURES of STEEL BALL TURNING LATHE:

in China, we are the most professional spherical turning lathes manufacturer. Our factory has the best technical support team. The spherical surface turning lathe will be customized according to differernt requirements.

TECHNICAL PARAMETERS:

| ITEM | UNIT | C6555 | C6595 | C65160 | C65180 |

| Max. Dia. of spherical | mm | 550 | 900 | 1600 | 1800 |

| Min. Dia. of spherical | mm | 50 | 260 | 1000 | 1200 |

| Dia. of spindle hole | mm | 100 | 130 | 100 | 100 |

| Taper of hole of spindle | mm | 120 | 140 | 140 | 140 |

| No. of spindle speeds | 18 | 21(12) | 21(12) | 21 | |

| Range of spindle speeds | r/min | 6~800 | 3.15~315 | 3.15~315 | 3.15~315 |

| Spindle reverse speeds | r/min | 11~838 | 3.5~291 | 3.5~291 | 3.5~291 |

| Swivel angle of toolpost | 90 | 90 | 55 | 55 | |

| Main power | kw | 11 | 22 | 30 | 30 |

| Weight | t | 4.4 | 12 | 25.4 | 27.4 |

| Length | mm | 3725 | 4700 | 6120 | 6220 |

| Width | mm | 1280 | 2500 | 2620 | 2720 |

| Height | mm | 1690 | 2000 | 2520 | 2620 |

FEATURES of STEEL BALL TURNING LATHE:

(1). the lathe bed adopts rectangular guide rails which with the best stability.

(2). the lathe spindle is of high precision which with 3 support structure.It can support heavy cutting.

(3). Operation is easy for workers.

(4). the rotary center line of the tool holder intersected with the rotating center line of the workpiece in order to ensure the roundness.

(5). You just need provide your workpiece and we will especially design precision lathe for you.

APPLICATION: (2). the lathe spindle is of high precision which with 3 support structure.It can support heavy cutting.

(3). Operation is easy for workers.

(4). the rotary center line of the tool holder intersected with the rotating center line of the workpiece in order to ensure the roundness.

(5). You just need provide your workpiece and we will especially design precision lathe for you.

Anyang Xinheng Machine Tool Co. Ltd. Is a professional machine tool manufacturer since 1946. Our factory covers an area of more than 30000 squares meters, equipped with our updated manufacturing facilities. We have LATHE, CNC LATHE, PIPE THREAD LATHE, SPHERE TURNING LATHE etc. We have attained ISO9001:2000 International Quality Control System Certification. Our products are sold both at home and abroad, and they are very popular around the world. Welcome to contact us!

Our service:

Free replacing parts available in the warranty period.

Cost price replacing parts available beyond the warranty period.

Quick action and reply for the technical questions at any time in the whole life of the machine.

Overseas after service center available in some region.

Engineer overseas service available on the requirement of customer(relative cost born by customer).

Free design drawing, free installation, free debugging, Cheap accessories.