| Brand Name: | PCB |

|---|---|

| Color: | black |

| material: | rubber |

| width: | 200-2200mm |

| type: | EP100-EP500, ST500-ST6300 |

| Place of Origin: | China (Mainland) |

Quick Details

Specifications

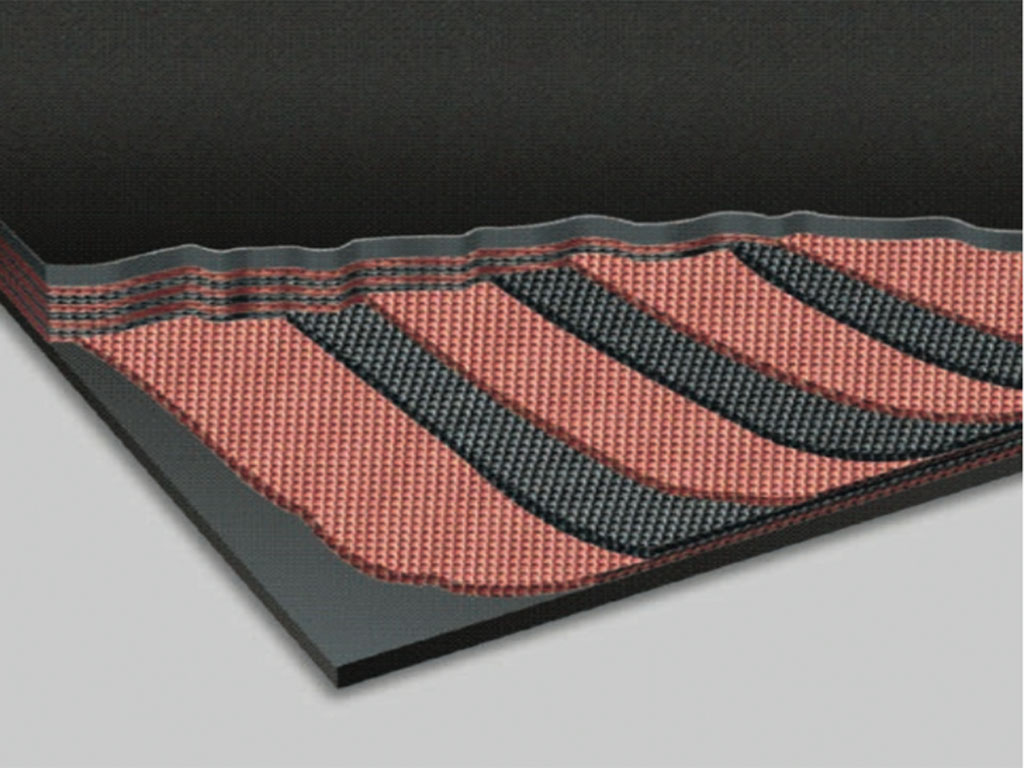

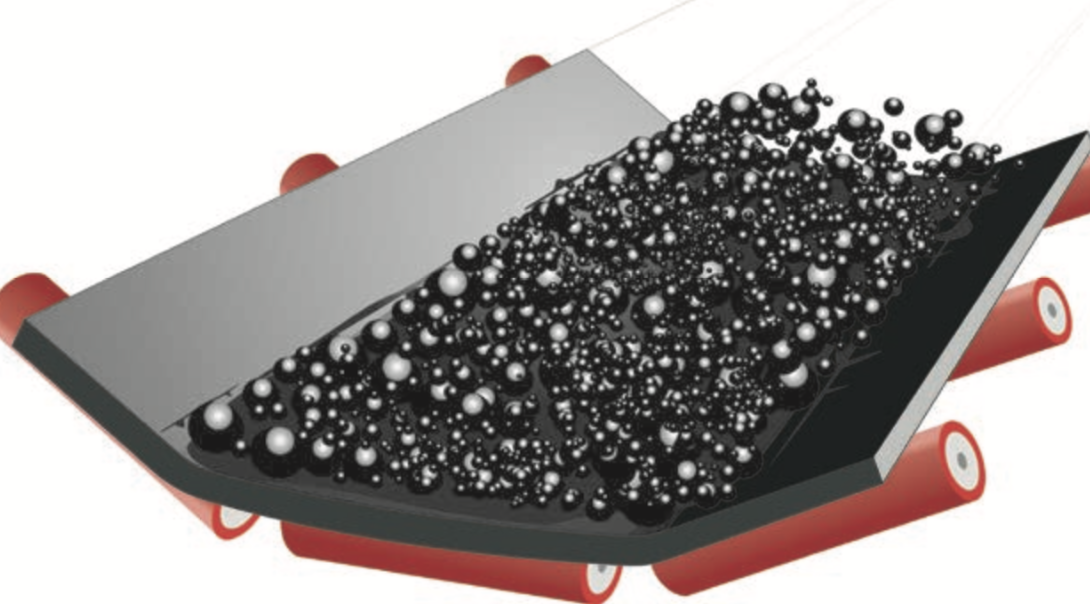

MULTIPLY FABRIC BELTING RANGE

PCB conveyor belting is an all synthetic multiply construction available in a very wide range of strengths and number of plies.

High performance industrial polyester and polyamide yarns are woven together, then given a special treatment to ensure exceptional long lasting ability to bond to the interply rubber. the interply rubber is formulated to provide not only high adhesion to prevent separation even in the most arduous applications but also to impart exceptional impact absorbing properties. Polyester warp yarns and polyamide weft in the traditional EP fabrics result in low elongation, exceptional fatigue and impact resistance and the ability of the belt to be joined by either vulcanised splice or mechanical fasteners. Breaking away from tradition, many of the belt fabrics are also available in high performance, economic all polyester (EE) construction.

PCB can offered with a wide range of rubber covers to suit a diverse range of applications from extreme abrasion, cutting and gouging to light duty conveying of non abrasive materials. the belt can be 6 meters width. the belt thickness can be over 50mm.

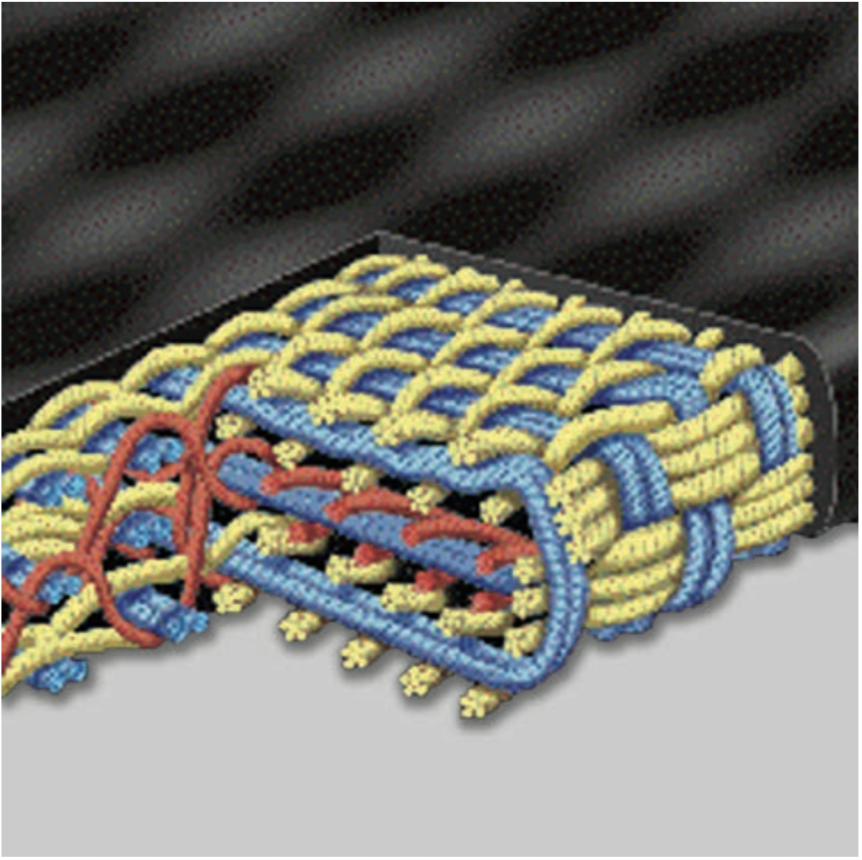

STEEL CORD CONVEYOR BELTING RANGE

PCB power cord is a steel cord reinforced conveyor belt incorporating the most current technology, many components have taken years of reinforcement to attain this technological precision. Every belt is guaranteed to provide maximum performance and maximum life.

Steel cord with galvanised steel cord strength carrying members embedded in a matrix of high performance rubber meets all demands for high strength, low elongation conveyor belting. the bonder rubber in the core is formulated to penetrate deep into the cords providing high cohesive and adhesive bond for long lasting protection and extreme join efficiency. Steel cord belt can be offered with a wide range of rubber covers to suit a diverse range of applications from extreme abrasion, cutting and gouging to less arduous conveying of non abrasive materials.

SOLID WOVEN CONVEYOR BELTING RANGE

Solid Woven technology is a solid woven construction conveyor belting having ultrafine polyester laments combined with cotton yarn in the warp members and high strength polyester/cotton blend weft members.

the combination allows deep penetration of PVC into the carcass that ensures the belt will not burn, meeting the most stringent standards of fire safety. Also the design ensures a tough belt that has superior rip resistance, excellent fastener holding capability and good abrasion resistance. Solid Woven conveyor belting is offered with abrasion resistant synthetic rubber covers that are chemically cross-linked to the PVC impregnation to ensure many years of trouble free service.

the cover thickness can be varied according to customer requirements.

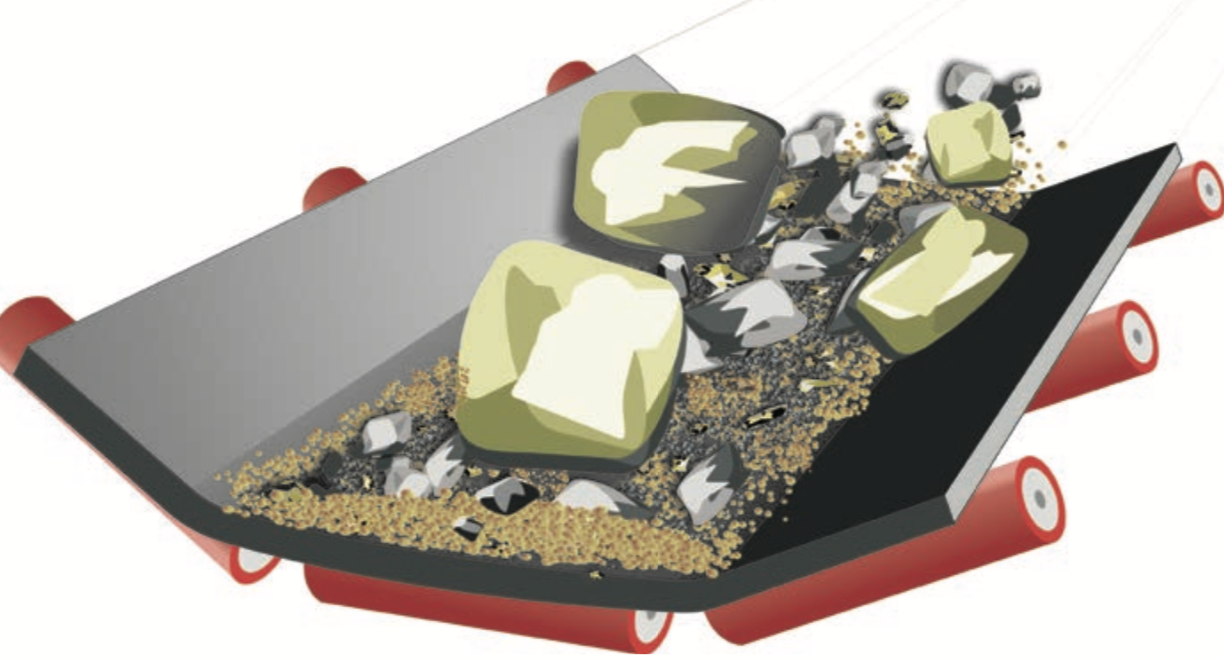

the CONVEYOR BELT COVER-WEAR RESISTANCE

the combination of tensile strength, abrasion resistance and elasticity of the conveyor cover are chosen to best suit the application in a range of cover types.

Abrasion resistance covers are in a league of their own when it comes to matching the life to the application. The mechanism of wear to conveyor belts is highly complex. Aninfinite mix of product size, sharpness and shape that strikes the belt surface at many different velocities all play a role. Also affecting rate of wear are the operating conditions.

the minmum abrasion can reach 50mm3 loss.

the CONVEYOR BELT COVER-Heat Resistance

We realize that there are not only an enormous range of different materials conveyed but also different temperature ranges that exist. First and foremost we understand that there needs to be differentiation between consistent or permanent heat and that of intermittent heat.

We have allowed for this in our temperature range and describe this in the table. It is always important to understand this, so as to benefit from the conveyor belt.

with all of this in mind we have developed and continue to develop and test our rubber covers so as to optimize heat requirement with optimal abrasion and tensile properties.

the CONVEYOR BELT COVER-OIL RESISTANCE

Oil resistance covers provide good tear, cut and abrasion resistance and also are resistant to swelling when caused by absorption of oils and grease.

the oil resistant cover is available in two grades. They are used when the material transported contains oils such as fuel oil in coal or fertilizers, lubrication oils in metal recycling, foundries, steel processes, waste industries or in the case of special processes such as glass or chemical.

the presence of oil in the transported material can have detrimental effects on standard rubber covers:

It will degrade the physical properties such as abrasion resistance, tensile strength and tear strength

the bel tcovers will absorb the oil causing them to swell and loose adhesion with the carcass.

the extent of degradation is depend on the type of oil and the temperature.

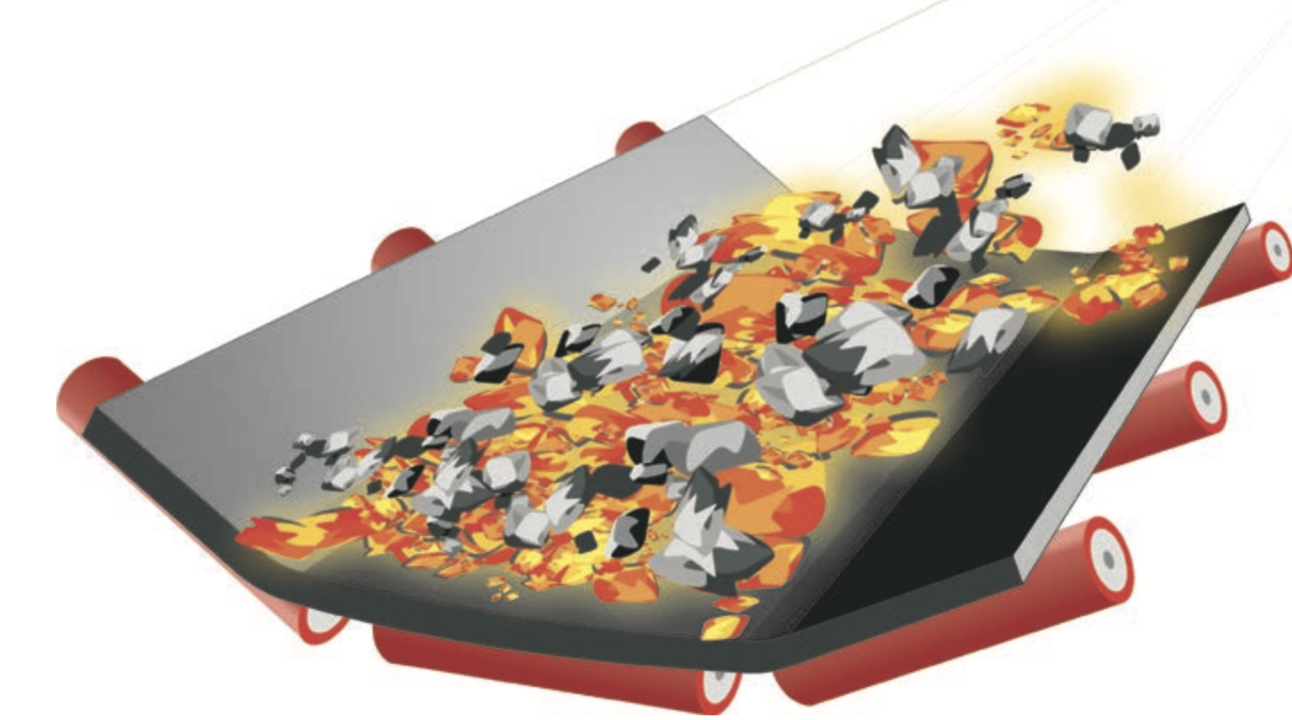

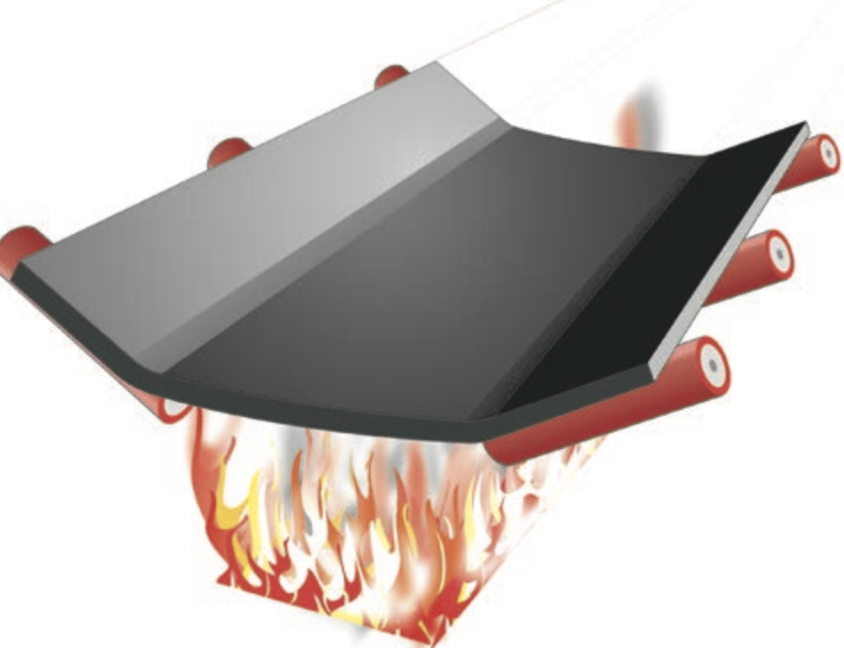

the CONVEYOR BELT COVER-FiRE RESISTANCE

the conveyor belting has rubber covers that provide good tear, cut, impact and abrasion resistance and is also re retardant.

the belt is available in a complete range of multiply strengths and also with steel cord reinforcement. Tests carried out on

Conveyor belting for determining are retarding properties.

1) Flame test - ISO 340:2013 test method

2) Electrical conductivity of the belt surface -ISO 284:2012 test method

3) Fire propagation test - EN 12881-1 test method

PCB conveyor belting is an all synthetic multiply construction available in a very wide range of strengths and number of plies.

High performance industrial polyester and polyamide yarns are woven together, then given a special treatment to ensure exceptional long lasting ability to bond to the interply rubber. the interply rubber is formulated to provide not only high adhesion to prevent separation even in the most arduous applications but also to impart exceptional impact absorbing properties. Polyester warp yarns and polyamide weft in the traditional EP fabrics result in low elongation, exceptional fatigue and impact resistance and the ability of the belt to be joined by either vulcanised splice or mechanical fasteners. Breaking away from tradition, many of the belt fabrics are also available in high performance, economic all polyester (EE) construction.

PCB can offered with a wide range of rubber covers to suit a diverse range of applications from extreme abrasion, cutting and gouging to light duty conveying of non abrasive materials. the belt can be 6 meters width. the belt thickness can be over 50mm.

STEEL CORD CONVEYOR BELTING RANGE

PCB power cord is a steel cord reinforced conveyor belt incorporating the most current technology, many components have taken years of reinforcement to attain this technological precision. Every belt is guaranteed to provide maximum performance and maximum life.

Steel cord with galvanised steel cord strength carrying members embedded in a matrix of high performance rubber meets all demands for high strength, low elongation conveyor belting. the bonder rubber in the core is formulated to penetrate deep into the cords providing high cohesive and adhesive bond for long lasting protection and extreme join efficiency. Steel cord belt can be offered with a wide range of rubber covers to suit a diverse range of applications from extreme abrasion, cutting and gouging to less arduous conveying of non abrasive materials.

SOLID WOVEN CONVEYOR BELTING RANGE

Solid Woven technology is a solid woven construction conveyor belting having ultrafine polyester laments combined with cotton yarn in the warp members and high strength polyester/cotton blend weft members.

the combination allows deep penetration of PVC into the carcass that ensures the belt will not burn, meeting the most stringent standards of fire safety. Also the design ensures a tough belt that has superior rip resistance, excellent fastener holding capability and good abrasion resistance. Solid Woven conveyor belting is offered with abrasion resistant synthetic rubber covers that are chemically cross-linked to the PVC impregnation to ensure many years of trouble free service.

the cover thickness can be varied according to customer requirements.

the CONVEYOR BELT COVER-WEAR RESISTANCE

the combination of tensile strength, abrasion resistance and elasticity of the conveyor cover are chosen to best suit the application in a range of cover types.

Abrasion resistance covers are in a league of their own when it comes to matching the life to the application. The mechanism of wear to conveyor belts is highly complex. Aninfinite mix of product size, sharpness and shape that strikes the belt surface at many different velocities all play a role. Also affecting rate of wear are the operating conditions.

the minmum abrasion can reach 50mm3 loss.

the CONVEYOR BELT COVER-Heat Resistance

We realize that there are not only an enormous range of different materials conveyed but also different temperature ranges that exist. First and foremost we understand that there needs to be differentiation between consistent or permanent heat and that of intermittent heat.

We have allowed for this in our temperature range and describe this in the table. It is always important to understand this, so as to benefit from the conveyor belt.

with all of this in mind we have developed and continue to develop and test our rubber covers so as to optimize heat requirement with optimal abrasion and tensile properties.

the CONVEYOR BELT COVER-OIL RESISTANCE

Oil resistance covers provide good tear, cut and abrasion resistance and also are resistant to swelling when caused by absorption of oils and grease.

the oil resistant cover is available in two grades. They are used when the material transported contains oils such as fuel oil in coal or fertilizers, lubrication oils in metal recycling, foundries, steel processes, waste industries or in the case of special processes such as glass or chemical.

the presence of oil in the transported material can have detrimental effects on standard rubber covers:

It will degrade the physical properties such as abrasion resistance, tensile strength and tear strength

the bel tcovers will absorb the oil causing them to swell and loose adhesion with the carcass.

the extent of degradation is depend on the type of oil and the temperature.

the CONVEYOR BELT COVER-FiRE RESISTANCE

the conveyor belting has rubber covers that provide good tear, cut, impact and abrasion resistance and is also re retardant.

the belt is available in a complete range of multiply strengths and also with steel cord reinforcement. Tests carried out on

Conveyor belting for determining are retarding properties.

1) Flame test - ISO 340:2013 test method

2) Electrical conductivity of the belt surface -ISO 284:2012 test method

3) Fire propagation test - EN 12881-1 test method