| Type: | Packaging Line |

|---|---|

| Brand Name: | Fushegn Sirui |

| Packaging Material: | Metal,Plastic,Wood |

| Packaging Type: | Bags,Cans,Cartons,Case,Pouch |

| Application: | Chemical,Commodity,Food,Machinery & Hardware,Medical |

| Type: | Check weigher |

| After-sales Service Provided: | Engineers available to service machinery overseas |

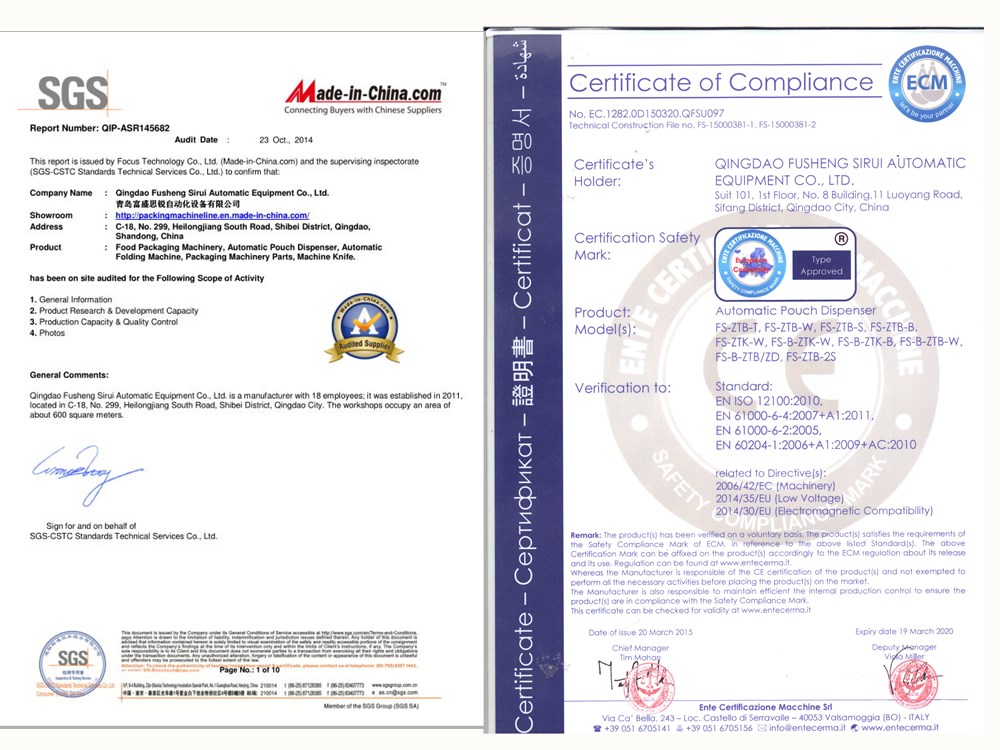

| Certification: | CE; ISO9001 |

| Weight: | 104kg |

| Dimension(L*W*H): | 750mm(height) |

| Model Number: | FS-220I |

| Place of Origin: | China (Mainland) |

| Power: | AC110V/220V 50-60HZ |

| Voltage: | AC110V/220V |

| Driven Type: | Electric |

| Automatic Grade: | Automatic |

| Condition: | New |

| Material: | Stainless Steel and aviation aluminum-alloy |

| Display: | Human Machine Interaction |

| Output speed: | 1-60 pcs./min |

| Weighing scale: | 1-1500g |

| Accuracy grade: | about 0.3g |

| Alarm: | Sound-light alarm |

| Other fuction: | customized |

Quick Details

Specifications

Check Weigher(FS-220I)

Check weigher is mainly used for automatic weight checking on food/pharmaceutical automatic production lines and logistics transportation systems.

Check Weigher(FS-220I) advantages:

1.the metel near the weight conveyor belt isAviation aluminum-alloywith light weight, so the weight sensor can be replace to 2kg, the accuracy will be improved a lot.

2. Multi-language support: Chinese, English, Spanish, Italian, Japanese, Korean, etc. (specified by the customer), default is Chinese and English

3. It can store 100 kinds of product detection data, which is convenient for users to call

4. USB data storage interface, report data can be transferred to PC for analysis and printing

5. Password setting protection, only for the administrator to operate.

6. Automatic zero tracking system, ensures the reliability of test data

7. Built - in temperature and noise compensation system to ensure system stability

8. Simple mechanical structure, convenient cleaning and maintenance.

9. Special shock absorbing and shockproof material is used to ensure long-term stability and service life

10. Online printing (customization is required)

11. External data communication interface, which can connect other equipment in the production line (eg: labelling machine and coding machine) (customization is required)

Specification

Configuration list:

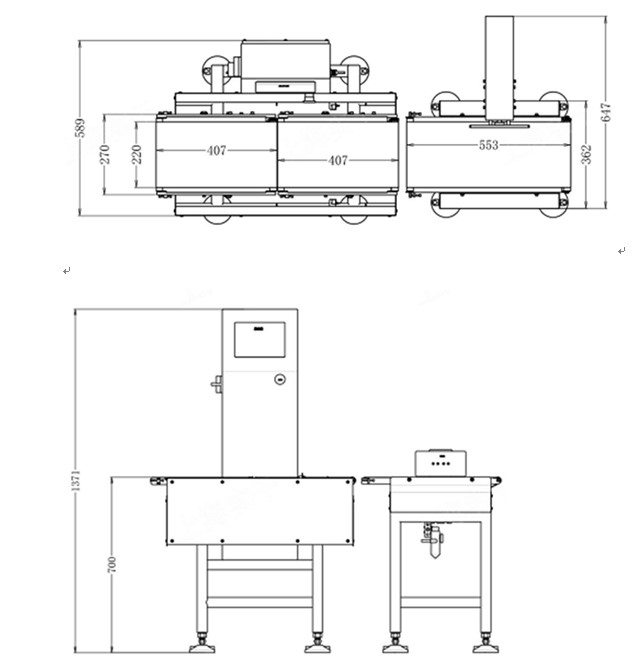

Outline dimensional drawing

Certificate:

Factory show(office):

Factory show( workshop):

FAQ:

Q1:how long does it take to deliver the machine after the order &Deposit?

A1:Usually it will take 30 working days to delivery for our regular products. If the machines need to be customized, it will take about 60 working days to manufacture the machine and make it ready to deliver.

.

Q2. What is the payment term?

A2: Our regular payment term is T/T 30% deposit,70% again B/L copy or L/C at sight.

Q3: Can you do the production as customized?

A3: Yes, we have a professional R&D team, the products could be customized on your requirements.

Check weigher is mainly used for automatic weight checking on food/pharmaceutical automatic production lines and logistics transportation systems.

Check Weigher(FS-220I) advantages:

1.the metel near the weight conveyor belt isAviation aluminum-alloywith light weight, so the weight sensor can be replace to 2kg, the accuracy will be improved a lot.

2. Multi-language support: Chinese, English, Spanish, Italian, Japanese, Korean, etc. (specified by the customer), default is Chinese and English

3. It can store 100 kinds of product detection data, which is convenient for users to call

4. USB data storage interface, report data can be transferred to PC for analysis and printing

5. Password setting protection, only for the administrator to operate.

6. Automatic zero tracking system, ensures the reliability of test data

7. Built - in temperature and noise compensation system to ensure system stability

8. Simple mechanical structure, convenient cleaning and maintenance.

9. Special shock absorbing and shockproof material is used to ensure long-term stability and service life

10. Online printing (customization is required)

11. External data communication interface, which can connect other equipment in the production line (eg: labelling machine and coding machine) (customization is required)

Specification

| No | Item | Specs. |

| 1 | Material | Stainless Steel and aviation aluminum-alloy |

| 2 | Display | Human Machine Interaction |

| 3 | Delivery direction | Facing the operation panel, from left to right |

| 4 | Carton dimension | L300mm, W220mm, H3mm |

| 5 | Output speed | 30 pcs./min.(1-60 pcs./min.) |

| 6 | Weighing scale | 5-1500g |

| 7 | Accuracy grade | About0.3G |

| 8 | Display scale | 0.1g |

| 9 | Weighing length | 407mm |

| 10 | Conveyor width | 220mm |

| 11 | Conveyor height above ground | 750mm 50mm |

| 12 | Despecking Type | Pushing type |

| 13 | Alarm | Sound-light alarm |

| 14 | Air requirement | Constant pressure air source |

| 15 | Power | AC110V/220V 50-60HZ |

| 16 | Weigher weight | about 60 kg +44kg |

Configuration list:

| No | Description | Brand |

| 1 | Weight sensor | HBM(Germany) |

| 2 | Frequency changer | Telta (Taiwan) |

| 3 | Touch screen | WEINVIEW (Taiwan) |

| 4 | Motor | Zhongda |

| 5 | Conveyer belt | Habasit (Switzerland) |

| 6 | Material | Stainless Steel and aviation aluminum-alloy |

Outline dimensional drawing

Certificate:

Factory show(office):

Factory show( workshop):

FAQ:

Q1:how long does it take to deliver the machine after the order &Deposit?

A1:Usually it will take 30 working days to delivery for our regular products. If the machines need to be customized, it will take about 60 working days to manufacture the machine and make it ready to deliver.

.

Q2. What is the payment term?

A2: Our regular payment term is T/T 30% deposit,70% again B/L copy or L/C at sight.

Q3: Can you do the production as customized?

A3: Yes, we have a professional R&D team, the products could be customized on your requirements.