| Surface Finishing: | Immersion silver |

|---|---|

| Board Thickness: | 1.1 mm |

| Copper Thickness: | 1.0 oz |

| Base Material: | RO4003C mixed with FR-4 |

| Brand Name: | Bicheng Enterprise Limited |

| Min. Line Spacing: | 5 mil |

| Min. Line Width: | 6 mil |

| Min. Hole Size: | 0.3mm |

| Model Number: | BIC-101-V101 |

| Place of Origin: | China (Mainland) |

| Solder Mask Color: | Blue |

| Colour of Component Legend: | White |

| TEST: | 100% Electrical Test prior shipment |

Quick Details

Specifications

Brief Introduction

with the development of electronic communication technology, the communication frequency

Is becoming higher and higher, and the high frequency signal transmission, need to use low

Dielectric constant (Dk), low dielectric loss (Df) but expensive special materials. these materials

Have cyanate and high frequency materials such as polytetrafluoroethylene / ceramic based

(PTFE/Ceramic), hydrocarbons / ceramic based materials (Hydra Carbon/Ceramic).

Usually these materials are expensive.

Reducing the cost is an important means for customers to improve the competitiveness of

Products. Therefore, the customers adopt the laminated structure of mixed materials in the

Design of PCB structure, that is, the necessary signal layer uses high-frequency materials to

the needs of signal transmission. Other line layers are made of conventional fiberglass epoxy

FR-4, which we call a hybrid board.

Available high frequency material (Core)

RO4350BRO4003C

4mil (0.1mm)8mil (0.203mm)

6.6mil (0.168mm)12mil (0.3mm)

10mil (0.254mm)20mil (0.508mm)

13.3mil (0.338mm)32mil (0.813mm)

20mil (0.508mm)60mil (1.524mm)

30mil (0.762mm)

60mil (1.524mm)

PCCB Case: 4 Layer Hybrid PCB with RO4003C + FR4

Combined

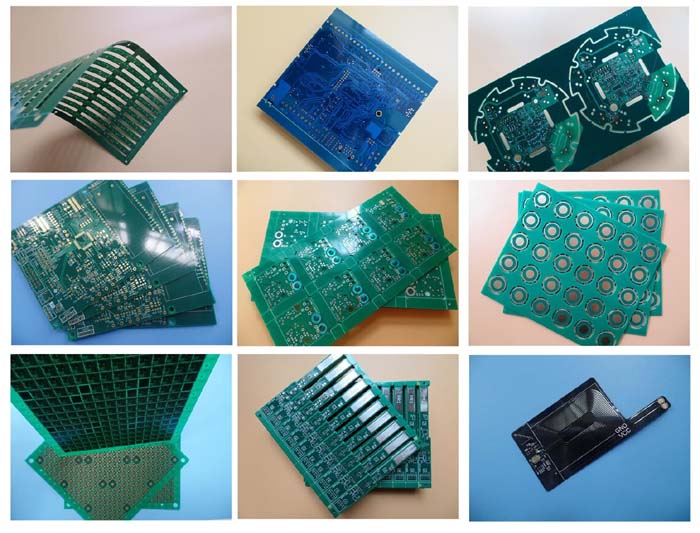

(PCB's are custom-made products, the picture and parameters shown are just for reference)

General description

this is a type of high frequency PCB built on RO4003C and FR4 combined for the application

of analogue transmitter. It's a 4 layer RF PCB board at 1.1 mm thick. It's immersion silver

Finish with blue solder mask and white silkscreen. It's fabricated per IPC 6012 Class 2 using

Supplied Gerber data. Each 20 boards are packed for shipment.

Features and benefits

the characteristic of low dielectric loss makes the signal loss at a lower level, which makes

the signal transmission of the whole equipment excellent.

Stable electrical coefficient of dielectric constant.

Delamination of copper foil will not be caused by the change of cold and heat due to the

Consistency with the thermal expansion coefficient of copper foil.

Immersion gold has excellent surface planarity, particularly helpful for PCBs with BGA

Packages or even CSP mounted components to reduce failure rate during assembly and

Soldering.

PCB manufacturing is strictly as per required specifications.

Meeting your printed circuit board needs from PCB prototyping to mass volume production.

Reduce manufacturing cost from advanced equipment import, worker training and technology

Improvement and management.

International approvals

RoHS materials

Application

Uhf radio, Directional coupler, Analogue transmitter, Base station antenna

Parameter and data sheet

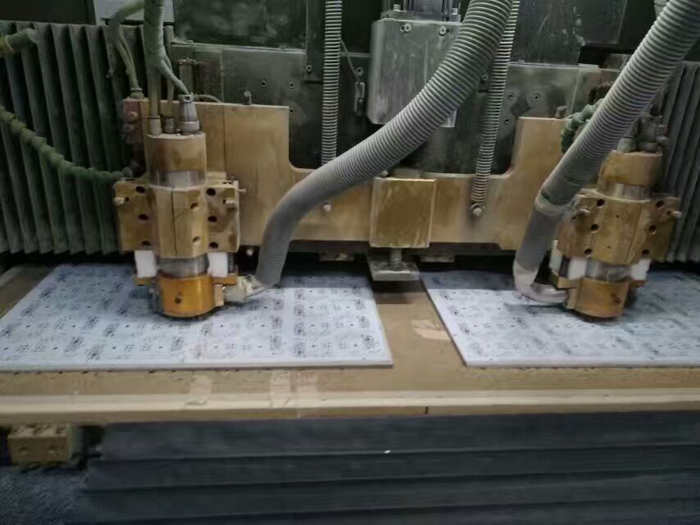

Variety of

Aluminum drill

with the development of electronic communication technology, the communication frequency

Is becoming higher and higher, and the high frequency signal transmission, need to use low

Dielectric constant (Dk), low dielectric loss (Df) but expensive special materials. these materials

Have cyanate and high frequency materials such as polytetrafluoroethylene / ceramic based

(PTFE/Ceramic), hydrocarbons / ceramic based materials (Hydra Carbon/Ceramic).

Usually these materials are expensive.

Reducing the cost is an important means for customers to improve the competitiveness of

Products. Therefore, the customers adopt the laminated structure of mixed materials in the

Design of PCB structure, that is, the necessary signal layer uses high-frequency materials to

the needs of signal transmission. Other line layers are made of conventional fiberglass epoxy

FR-4, which we call a hybrid board.

Available high frequency material (Core)

RO4350BRO4003C

4mil (0.1mm)8mil (0.203mm)

6.6mil (0.168mm)12mil (0.3mm)

10mil (0.254mm)20mil (0.508mm)

13.3mil (0.338mm)32mil (0.813mm)

20mil (0.508mm)60mil (1.524mm)

30mil (0.762mm)

60mil (1.524mm)

PCCB Case: 4 Layer Hybrid PCB with RO4003C + FR4

Combined

(PCB's are custom-made products, the picture and parameters shown are just for reference)

General description

this is a type of high frequency PCB built on RO4003C and FR4 combined for the application

of analogue transmitter. It's a 4 layer RF PCB board at 1.1 mm thick. It's immersion silver

Finish with blue solder mask and white silkscreen. It's fabricated per IPC 6012 Class 2 using

Supplied Gerber data. Each 20 boards are packed for shipment.

Features and benefits

the characteristic of low dielectric loss makes the signal loss at a lower level, which makes

the signal transmission of the whole equipment excellent.

Stable electrical coefficient of dielectric constant.

Delamination of copper foil will not be caused by the change of cold and heat due to the

Consistency with the thermal expansion coefficient of copper foil.

Immersion gold has excellent surface planarity, particularly helpful for PCBs with BGA

Packages or even CSP mounted components to reduce failure rate during assembly and

Soldering.

PCB manufacturing is strictly as per required specifications.

Meeting your printed circuit board needs from PCB prototyping to mass volume production.

Reduce manufacturing cost from advanced equipment import, worker training and technology

Improvement and management.

International approvals

RoHS materials

Application

Uhf radio, Directional coupler, Analogue transmitter, Base station antenna

Parameter and data sheet

| PCB SIZE | 70 x 12mm=1PCS |

| BOARD TYPE | Hybrid PCB |

| Number of Layers | Multilayer PCB, 4 layer PCB |

| Surface Mount Components | YES |

| through Hole Components | NO |

| LAYER STACKUP | Copper ------- 35um(1oz)+plate TOP layer |

| RO4003C 0.203mm (8 mil) | |

| Copper ------- 35um(1oz) MidLayer 1 | |

| FR-4 0.50 mm | |

| Copper ------- 35um(1oz) MidLayer 2 | |

| FR-4 0.20 mm | |

| Copper ------- 17um(0.5oz)+plate BOT Layer | |

| TECHNOLOGY | |

| Minimum Trace and Space: | 5 mil / 6 mil |

| Minimum / Maximum Holes: | 0.3/5.5 mm |

| Number of Different Holes: | 8 |

| Number of Drill Holes: | 97 |

| Number of Milled Slots: | 0 |

| Number of Internal Cutouts: | 1 |

| Impedance Control: | no |

| Number of Gold finger: | 0 |

| BOARD MATERIAL | |

| Glass Epoxy: | RO4003C 0.203 mm (8 mil) and FR-4 0.20 mm combined |

| Final foil external: | 1oz |

| Final foil internal: | 1oz |

| Final height of PCB: | 1.1mm 0.11 |

| PLATING and COATING | |

| Surface Finish | Immersion Silver |

| Solder Mask Apply to: | Top and Bottom side |

| Solder Mask Color: | Blue, KSM-6189BL04/KSM-19H01 |

| Solder Mask Type: | LPSM |

| CONTOUR/CUTTING | Routing |

| MARKING | |

| Side of Component Legend | Top |

| Colour of Component Legend | White |

| Manufacturer Name or Logo: | N/A |

| VIA | Plated through hole(PTH), via open |

| FLAMIBILITY RATING | UL 94-V0 Approval MIN. |

| DIMENSION TOLERANCE | |

| Outline dimension: | 0.0059" (0.15mm) |

| Board plating: | 0.0030" (0.076mm) |

| Drill tolerance: | 0.002" (0.05mm) |

| TEST | 100% Electrical Test prior shipment |

| TYPE of ARTWORK to BE SUPPLIED | Gerber RS-274-X, PCBDOC etc |

| SERVICE AREA | Worldwide, Globally. |

Variety of

Aluminum drill