| Surface Finishing: | Electroless nickel over Immersion Gold (ENIG) |

|---|---|

| Board Thickness: | 0.1mm |

| Copper Thickness: | 1.0 oz |

| Base Material: | Polyimide 0.1mm, FPC |

| Brand Name: | Bicheng Enterprise Limited |

| Min. Line Spacing: | 12 mil |

| Min. Line Width: | 12 mil |

| Min. Hole Size: | 2.5mm |

| Model Number: | BIC-251-V251 |

| Place of Origin: | China (Mainland) |

| Solder Mask Color: | Yellow, Coverlay |

| Colour of Component Legend: | White |

| TEST: | 100% Electrical Test prior shipment |

Quick Details

Specifications

Brief Introduction of FPC

Flexible Printed Circuit Board (FPC) is referred to as "soft board". In the industry, FPC is a

Printed circuit board made of flexible insulating substrate (mainly polyimide or polyester film),

Which has many advantages that rigid printed circuit boards do not have. for example, it can

Be freely bent, wound, folded. the volume of electronic products can be greatly reduced by

Using FPC, which is suitable for the development of electronic products in the direction of high

Density, miniaturization and high reliability. Therefore, FPC has been widely used in aerospace,

Military, laptop, computer peripherals, PDA, digital camera and other fields or products.

FPC also has the advantages of good heat dissipation,

Solderability, easy mounting and low cost.

Flexible printed circuit board has one layer, two layers and multilayer board. the base material

Is polyimide clad laminate. this kind of material has high heat resistance and good dimensional

Stability. It is the final product through pressing with the coating film which has both mechanical

Protection and good electrical insulation. the surface and inner conductors of double-sided and

Multi-layer printed circuit boards are metallized to realize the electrical connection of inner

and outer layers.

the function of flexible circuit board can be divided into four kinds, namely, lead line,

Printed circuit, connector and multifunction integrated system, which cover computer,

Computer peripheral auxiliary system, consumer household electrical appliance and

Automobile, etc.

FPC Case: Single Sided Flexible Printed Circuit (FPC)

Built on Polyimide with Immersion Gold

(FPC's are custom-made products, the picture and parameters shown are just for

Reference)

General description

this is a type of flexible printed circuit for the application of Bluetooth Headset. It's a single

Sided layer FPC at 0.15mm thick. the base laminate is from Shengyi. It's fabricated per IPC

6012 Class 2 using supplied Gerber data. Polyimide stiffener is applied on the inserting part.

Parameter and data sheet

Features and benefits

Excellent flexibility

Reducing the volume

Weight reduction

Consistency of assembly

Increased reliability

Controllability of electrical parameter design

the end can be whole soldered

Material optionality

Low cost

Continuity of processing

No minimum order quantity and low cost sample.

More than 15 years of experience

Application

Thin-film switch,Medical keypad soft board

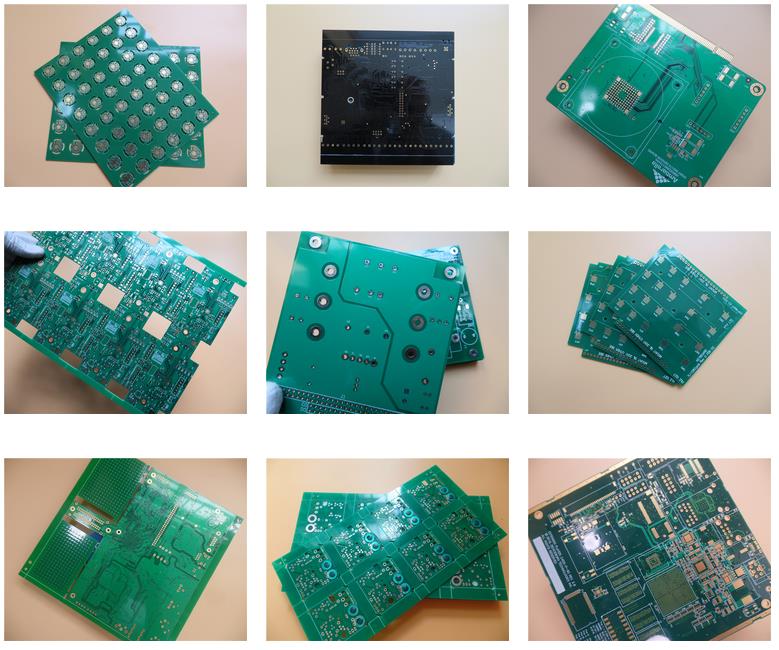

Variety of PCBs

PCB Film exposure

Flexible Printed Circuit Board (FPC) is referred to as "soft board". In the industry, FPC is a

Printed circuit board made of flexible insulating substrate (mainly polyimide or polyester film),

Which has many advantages that rigid printed circuit boards do not have. for example, it can

Be freely bent, wound, folded. the volume of electronic products can be greatly reduced by

Using FPC, which is suitable for the development of electronic products in the direction of high

Density, miniaturization and high reliability. Therefore, FPC has been widely used in aerospace,

Military, laptop, computer peripherals, PDA, digital camera and other fields or products.

FPC also has the advantages of good heat dissipation,

Solderability, easy mounting and low cost.

Flexible printed circuit board has one layer, two layers and multilayer board. the base material

Is polyimide clad laminate. this kind of material has high heat resistance and good dimensional

Stability. It is the final product through pressing with the coating film which has both mechanical

Protection and good electrical insulation. the surface and inner conductors of double-sided and

Multi-layer printed circuit boards are metallized to realize the electrical connection of inner

and outer layers.

the function of flexible circuit board can be divided into four kinds, namely, lead line,

Printed circuit, connector and multifunction integrated system, which cover computer,

Computer peripheral auxiliary system, consumer household electrical appliance and

Automobile, etc.

FPC Case: Single Sided Flexible Printed Circuit (FPC)

Built on Polyimide with Immersion Gold

(FPC's are custom-made products, the picture and parameters shown are just for

Reference)

General description

this is a type of flexible printed circuit for the application of Bluetooth Headset. It's a single

Sided layer FPC at 0.15mm thick. the base laminate is from Shengyi. It's fabricated per IPC

6012 Class 2 using supplied Gerber data. Polyimide stiffener is applied on the inserting part.

Parameter and data sheet

| PCB SIZE | 45 x 33mm=1PCS |

| BOARD TYPE | |

| Number of Layers | Single sided PCB |

| Surface Mount Components | YES |

| through Hole Components | no |

| LAYER STACKUP | Copper ------- 35um(1oz) |

| Polyimide 0.1mm | |

| TECHNOLOGY | |

| Minimum Trace and Space: | 12mil/12mil |

| Minimum / Maximum Holes: | 2.5mm |

| Number of Different Holes: | 1 |

| Number of Drill Holes: | 2 |

| Number of Milled Slots: | 0 |

| Number of Internal Cutouts: | 0 |

| Impedance Control | NO |

| BOARD MATERIAL | |

| Glass Epoxy: | Polyimide 0.1mm, FPC |

| Final foil external: | 1oz |

| Final foil internal: | 0oz |

| Final height of PCB: | 0.1mm 0.05 |

| PLATING and COATING | |

| Surface Finish | Electroless nickel over Immersion Gold (ENIG)( 1 " over 100 " nickel) |

| Solder Mask Apply to: | TOP |

| Solder Mask Color: | Yellow, Coverlay |

| Solder Mask Type: | LPSM |

| CONTOUR/CUTTING | Laser cut |

| MARKING | |

| Side of Component Legend | TOP |

| Colour of Component Legend | White, IJR-4000 MW300, Taiyo Supplied. |

| Manufacturer Name or Logo: | Marked on the board in a conductor and leged FREE AREA |

| VIA | None Plated through Hole(NPTH) |

| FLAMIBILITY RATING | UL 94-V0 Approval MIN. |

| DIMENSION TOLERANCE | |

| Outline dimension: | 0.0059" (0.15mm) |

| Board plating: | 0.0030" (0.076mm) |

| Drill tolerance: | 0.002" (0.05mm) |

| TEST | 100% Electrical Test prior shipment |

| TYPE of ARTWORK to BE SUPPLIED | Gerber RS-274-X, PCBDOC etc |

| SERVICE AREA | Worldwide, Globally. |

Features and benefits

Excellent flexibility

Reducing the volume

Weight reduction

Consistency of assembly

Increased reliability

Controllability of electrical parameter design

the end can be whole soldered

Material optionality

Low cost

Continuity of processing

No minimum order quantity and low cost sample.

More than 15 years of experience

Application

Thin-film switch,Medical keypad soft board

Variety of PCBs

PCB Film exposure