| Surface Finishing: | Immersion Gold |

|---|---|

| Board Thickness: | 1.6mm |

| Copper Thickness: | 35 um (1oz) |

| Base Material: | FR-4 1.6mm / Polyimide 25um |

| Brand Name: | Bicheng Enterprise Limited |

| Min. Line Spacing: | N/A |

| Min. Line Width: | N/A |

| Min. Hole Size: | N/A |

| Model Number: | BIC-269-V269 |

| Place of Origin: | China (Mainland) |

| Coverlay Colour: | Yellow Coverlayer / Green solder mask |

| Color of Silkscreen: | White |

| Function: | 100% Pass electrical test |

Quick Details

Specifications

Brief Introduction of FPC

Flexible Printed Circuit Board (FPC) is referred to as "soft board". In the industry, FPC is

A printed circuit board made of flexible insulating substrate (mainly polyimide or polyester

Film), which has many advantages that rigid printed circuit boards do not have. for example,

It can be freely bent, wound, folded. the volume of electronic products can be greatly reduced

by using FPC, which is suitable for the development of electronic products in the direction of

High density, miniaturization and high reliability. Therefore, FPC has been widely used in

Aerospace, military, laptop, computer peripherals, PDA, digital camera and other fields or

Products.

FPC also has the advantages of good heat dissipation,

Solderability, easy mounting and low cost.

Flexible printed circuit board has one layer, two layers and multilayer board. the base material

Is polyimide clad laminate. this kind of material has high heat resistance and good dimensional

Stability. It is the final product through pressing with the coating film which has both mechanical

Protection and good electrical insulation. the surface and inner conductors of double-sided and

Multi-layer printed circuit boards are metallized to realize the electrical connection of inner and

Outer layers.

the function of flexible circuit board can be divided into four kinds, namely, lead line, printed

Circuit, connector and multifunction integrated system, which cover computer, computer

Peripheral auxiliary system, consumer household electrical appliance and automobile, etc.

FPC Case: 4 Layer Rigid-Flex PCB Built on 1.6mm

FR4 and 0.2mm Polyimide

(FPC's are custom-made products, the picture and parameters shown are just for reference)

General description

this is a type of rigid flex PCB for the application of Portable Sound Systems. It's a 4 layer

PCB with flexible part in the middle. the base laminate is from Shengyi, It's fabricated per

IPC 6012 Class 2 using supplied Gerber data.

Parameter and data sheet

Features and benefits

Excellent flexibility

Reducing the volume

Weight reduction

Consistency of assembly

Increased reliability

Controllability of electrical parameter design

the end can be whole soldered

Material optionality

Low cost

Continuity of processing

Professional and experienced engineers

Engineering design prevents problems from occurring in pre-production.

Application

Instrument panel,Camera flex board,Tablet antenna soft board

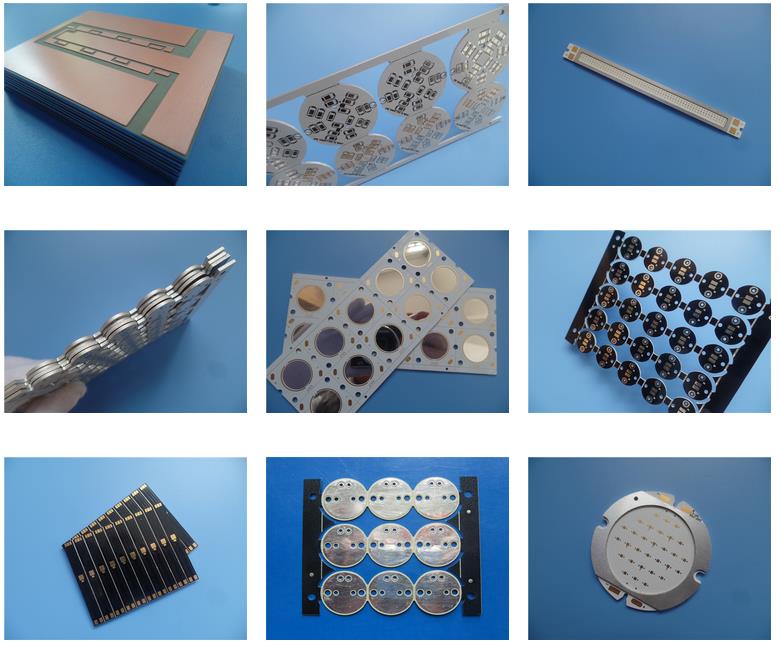

Variety of PCBs

CNC Routing

Flexible Printed Circuit Board (FPC) is referred to as "soft board". In the industry, FPC is

A printed circuit board made of flexible insulating substrate (mainly polyimide or polyester

Film), which has many advantages that rigid printed circuit boards do not have. for example,

It can be freely bent, wound, folded. the volume of electronic products can be greatly reduced

by using FPC, which is suitable for the development of electronic products in the direction of

High density, miniaturization and high reliability. Therefore, FPC has been widely used in

Aerospace, military, laptop, computer peripherals, PDA, digital camera and other fields or

Products.

FPC also has the advantages of good heat dissipation,

Solderability, easy mounting and low cost.

Flexible printed circuit board has one layer, two layers and multilayer board. the base material

Is polyimide clad laminate. this kind of material has high heat resistance and good dimensional

Stability. It is the final product through pressing with the coating film which has both mechanical

Protection and good electrical insulation. the surface and inner conductors of double-sided and

Multi-layer printed circuit boards are metallized to realize the electrical connection of inner and

Outer layers.

the function of flexible circuit board can be divided into four kinds, namely, lead line, printed

Circuit, connector and multifunction integrated system, which cover computer, computer

Peripheral auxiliary system, consumer household electrical appliance and automobile, etc.

FPC Case: 4 Layer Rigid-Flex PCB Built on 1.6mm

FR4 and 0.2mm Polyimide

(FPC's are custom-made products, the picture and parameters shown are just for reference)

General description

this is a type of rigid flex PCB for the application of Portable Sound Systems. It's a 4 layer

PCB with flexible part in the middle. the base laminate is from Shengyi, It's fabricated per

IPC 6012 Class 2 using supplied Gerber data.

Parameter and data sheet

| Size of Flexible PCB | 60.22 X 132.27mm |

| Number of Layers | 4 |

| Board Type | Rigid-flex PCB |

| Board Thickness | 1.6mm |

| Board Material | FR-4 1.6mm / Polyimide 25m |

| Board Material Supplier | Shengyi |

| Tg Value of Board Material | 60 |

| PTH Cu thickness | 20 m |

| Inner Iayer Cu thicknes | 35 m |

| Surface Cu thickness | 35 m |

| Coverlay Colour | Yellow Coverlayer / Green solder mask |

| Number of Coverlay | 2 |

| Thickness of Coverlay | 25 m |

| Stiffener Material | no |

| Stiffener Thickness | N/A |

| Type of Silkscreen Ink | IJR-4000 MW300 |

| Supplier of Silkscreen | TAIYO |

| Color of Silkscreen | White |

| Number of Silkscreen | 2 |

| Peeling test of Coverlay | No peelable |

| Legend Adhesion | 3M 90 No peeling after Min. 3 times test |

| Surface Finish | Immersion Gold |

| Thickness of Nickle/Gold | Au: 0.03m(Min.); Ni 2-4m |

| RoHS Required | Yes |

| Famability | 94-V0 |

| Thermal Shock Test | Pass, -25125, 1000 cycles. |

| Thermal Stress | Pass, 3005,10 seconds, 3 cycles. No delamination, no Blistering. |

| Function | 100% Pass electrical test |

| Workmanship | Compliance with IPC-A-600H & IPC-6013C Class 2 |

Features and benefits

Excellent flexibility

Reducing the volume

Weight reduction

Consistency of assembly

Increased reliability

Controllability of electrical parameter design

the end can be whole soldered

Material optionality

Low cost

Continuity of processing

Professional and experienced engineers

Engineering design prevents problems from occurring in pre-production.

Application

Instrument panel,Camera flex board,Tablet antenna soft board

Variety of PCBs

CNC Routing