| Surface Finishing: | Immersion Gold |

|---|---|

| Board Thickness: | 0.25mm |

| Copper Thickness: | 70 um |

| Base Material: | Polyimide 25um |

| Brand Name: | Bicheng Enterprise Limited |

| Min. Line Spacing: | N/A |

| Min. Line Width: | N/A |

| Min. Hole Size: | N/A |

| Model Number: | BIC-314-V314 |

| Place of Origin: | China (Mainland) |

| Coverlay Colour: | Yellow |

| Color of Silkscreen: | White |

Quick Details

Specifications

Structure of FPC

According to the number of layers of conductive copper foil, FPC can be divided into single

Layer circuit, double layer circuit, multi-layer circuit, double sided and so on.

Single-layer structure: the flexible circuit of this structure is the simplest structure of the

Flexible PCB. Usually the base material (dielectric substrates) + transparent rubber(adhesive)

+ copper foil is a set of purchased raw materials(semi-manufactures), the protective film

and transparent glue are another kind of bought raw material. First, copper foil must be

Etched to obtain the required circuit, and the protective film should be drilled to reveal

the corresponding pad. after cleaning, the two are combined by rolling. Then the exposed

Part of the pad electroplated gold or tin to protect. In this way, the big panel board will

Be ready. Generally also it's stamped into the corresponding shape of the small circuit

Board. There is also no protective film directly on the copper foil, but printed resistance

Soldering coating, so that the cost will be lower, but the mechanical strength of the circuit

Board will become worse. unless the strength requirement is not high and the price needs

to be as low as possible, it is best to apply the protective film method.

Double layer structure: when the circuit is too complex to be wired, or copper foil is needed

to shield the ground, it is necessary to choose a double layer or even a multilayer. the most

Typical difference between a multilayer and a single plate is the addition of a perforated structure

to connect the layers of copper foil. the first process of transparent rubber + base material +

Copper foil is to make holes. Drill holes in the base material and copper foil first, clean and then

Plated with a certain thickness of copper. the subsequent fabrication process is almost the same

as the single-layer circuit.

Double sided structure: both sides of the double sided FPC have pads, mainly used to connect

Other circuit boards. Although it and monolayer structure is similar, but the manufacturing

Process is very different. Its raw material is copper foil, protective film and transparent glue.

the protective film should be drilled according to the position of the pad first, then the copper

Foil should be affixed, the pad and track lines should be etched and then the protective film

of another drilled hole should be affixed.

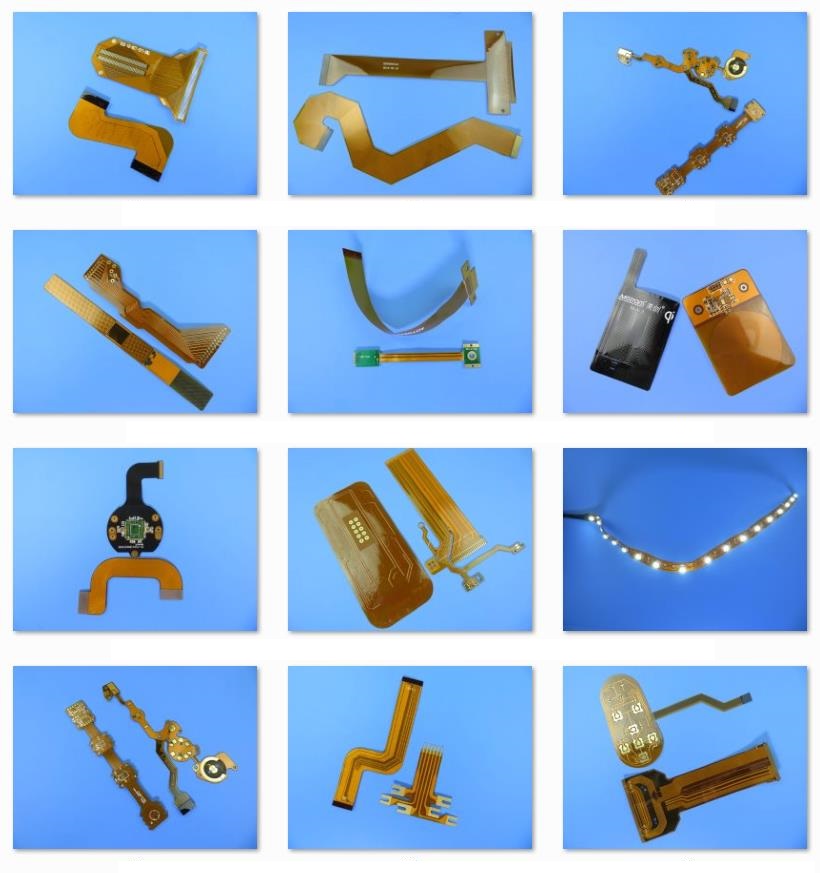

FPC Case: Flexible Printed Circuit (FPC) Built on 2oz

Polyimide for Analog Controller

(Flexible printed circuits are custom-made products, the picture and parameters shown

Are just for reference)

General description

this is a type of 2 Layer flexible printed circuit (FPC) built on 2oz polyimide for the

Application of Analog Controller.

Basic specifications

Base material: Polyimide 25m

Layer count: 2 layers

Type: Individual FPC

Format: 97mm x 51.5mm = 1 type = 1 piece

Surface finish: Immersion gold

Copper weight: Outer layer 70m/ Inner layer 0 m

Solder mask / Legend: Yellow coverlay / White

Final PCB height: 0.25 mm

Standard: IPC 6012 Class 2

Packing: 100 pieces are packed for shipment.

Lead time: 10 working days

Shelf life: 6 months

Features and benefits

Controllability of electrical parameter design;

the end can be whole soldered;

Low cost;

High solderability, no stressing of circuit boards and less contamination of PCB surface;

Meeting your PCB needs from prototype to mass production;

RoHS materials;

Eligible products rate of first production: >95%

Customer complaint rate: <1%

Application

Capacitive touch screen / panel, Toy lamp strip, industrial surveying and mapping

Instrument, medical equipment controller, Toy lamp strip, industrial control audio

Equipment

General Properties of Coverlay

Explanations:

C = Humidity conditioning;

E = Temperature conditioning;

1. Testing after laminating with shining side of copper foil in suitable condition;

* Certified to IPC-4203/2 Epoxy adhesive on one or two sides of polyimide dielectirc

Product Code Description

SF305C 05 15

SF305C: Shengyi Coverlay Designation

05: PI Film Thickness, 05- 12.5m; 10-25m

15: Adhesive Thickness, 15-15m, 25- 25m; 35- 35m

FPC

Film Exposure machine

According to the number of layers of conductive copper foil, FPC can be divided into single

Layer circuit, double layer circuit, multi-layer circuit, double sided and so on.

Single-layer structure: the flexible circuit of this structure is the simplest structure of the

Flexible PCB. Usually the base material (dielectric substrates) + transparent rubber(adhesive)

+ copper foil is a set of purchased raw materials(semi-manufactures), the protective film

and transparent glue are another kind of bought raw material. First, copper foil must be

Etched to obtain the required circuit, and the protective film should be drilled to reveal

the corresponding pad. after cleaning, the two are combined by rolling. Then the exposed

Part of the pad electroplated gold or tin to protect. In this way, the big panel board will

Be ready. Generally also it's stamped into the corresponding shape of the small circuit

Board. There is also no protective film directly on the copper foil, but printed resistance

Soldering coating, so that the cost will be lower, but the mechanical strength of the circuit

Board will become worse. unless the strength requirement is not high and the price needs

to be as low as possible, it is best to apply the protective film method.

Double layer structure: when the circuit is too complex to be wired, or copper foil is needed

to shield the ground, it is necessary to choose a double layer or even a multilayer. the most

Typical difference between a multilayer and a single plate is the addition of a perforated structure

to connect the layers of copper foil. the first process of transparent rubber + base material +

Copper foil is to make holes. Drill holes in the base material and copper foil first, clean and then

Plated with a certain thickness of copper. the subsequent fabrication process is almost the same

as the single-layer circuit.

Double sided structure: both sides of the double sided FPC have pads, mainly used to connect

Other circuit boards. Although it and monolayer structure is similar, but the manufacturing

Process is very different. Its raw material is copper foil, protective film and transparent glue.

the protective film should be drilled according to the position of the pad first, then the copper

Foil should be affixed, the pad and track lines should be etched and then the protective film

of another drilled hole should be affixed.

FPC Case: Flexible Printed Circuit (FPC) Built on 2oz

Polyimide for Analog Controller

(Flexible printed circuits are custom-made products, the picture and parameters shown

Are just for reference)

General description

this is a type of 2 Layer flexible printed circuit (FPC) built on 2oz polyimide for the

Application of Analog Controller.

Basic specifications

Base material: Polyimide 25m

Layer count: 2 layers

Type: Individual FPC

Format: 97mm x 51.5mm = 1 type = 1 piece

Surface finish: Immersion gold

Copper weight: Outer layer 70m/ Inner layer 0 m

Solder mask / Legend: Yellow coverlay / White

Final PCB height: 0.25 mm

Standard: IPC 6012 Class 2

Packing: 100 pieces are packed for shipment.

Lead time: 10 working days

Shelf life: 6 months

Features and benefits

Controllability of electrical parameter design;

the end can be whole soldered;

Low cost;

High solderability, no stressing of circuit boards and less contamination of PCB surface;

Meeting your PCB needs from prototype to mass production;

RoHS materials;

Eligible products rate of first production: >95%

Customer complaint rate: <1%

Application

Capacitive touch screen / panel, Toy lamp strip, industrial surveying and mapping

Instrument, medical equipment controller, Toy lamp strip, industrial control audio

Equipment

General Properties of Coverlay

| Test Item | Treatment Condition |

Unit | Property Date | |||

| IPC Standard * value |

Typical Value | |||||

| SF305C 0205 |

SF305C 0309 | |||||

| Resin Flow | A | mm | - | 0.15 | 0.15 | |

| Peeling Strength (90) | A | N/mm | 0.7 | 0.82 | 1.06 | |

| 288, 5s | 0.53 | 0.80 | 1.11 | |||

| Thermal Stress | 288, 20s | - | - | No Delamination |

No Delamination | |

| Dimensional Stability | MD | after peeling off the paper |

% | 0.2 | 0.1 | 0.1 |

| TD | 0.1 | 0.1 | ||||

| Chemical Resistance | after Chemical Exposure |

% | 80 | 90 | 90 | |

| Volume Resistvitiy | C-96/35/90 | M-cm | 10^6 | 7.8 x 10^6 | 2.2 x 10^7 | |

| Surface Resistance | C-96/35/90 | M | 10^4 | 2.5 x 10^5 | 4.2 x 10^5 | |

Explanations:

C = Humidity conditioning;

E = Temperature conditioning;

1. Testing after laminating with shining side of copper foil in suitable condition;

* Certified to IPC-4203/2 Epoxy adhesive on one or two sides of polyimide dielectirc

Product Code Description

SF305C 05 15

SF305C: Shengyi Coverlay Designation

05: PI Film Thickness, 05- 12.5m; 10-25m

15: Adhesive Thickness, 15-15m, 25- 25m; 35- 35m

FPC

Film Exposure machine