| Surface Finishing: | Immersion Gold |

|---|---|

| Board Thickness: | 0.20mm |

| Copper Thickness: | 35 um (1oz) |

| Base Material: | Polyimide 25um |

| Brand Name: | Bicheng Enterprise Limited |

| Min. Line Spacing: | N/A |

| Min. Line Width: | N/A |

| Min. Hole Size: | N/A |

| Model Number: | BIC-342-V342 |

| Place of Origin: | China (Mainland) |

| Coverlay Colour: | Black |

| Color of Silkscreen: | White |

Quick Details

Specifications

Overview

A breakdown of a flexible circuit shows that it consists of 3 basic elements: copper foil,

Dielectric material and adhesive. most of the manufacturing processes, i.e. Imaging transfer,

Plating and etching, are quite similar to those used when producing plated-through boards.

however, there're differences due to the thin and floppy material used in flexible circuits.

Bicheng Flexible Printed Circuit Capability 2019

Purpose of Flexible Circuits

1) to provide interconnections between printed circuit boards and other components.

2) to serve as three-dimensional substrates for the mounting of SMT components, e.g.,

in

Photographic and video cameras.

3) to establish interconnections capable of withstanding dynamic flexing.

4) to form part of rigid-flex circuit boards.

Advantages

1) Flexibility

2) Volume decreases

3) Weight reduces

4) Consistency of SMD mounting

5) Reliability increases

6) Controllability of electrical design of parameters

7) Tin soldered overall on the FPC end

8) Material optional (PI, PET)

9) Low cost

10) Continuity of processing

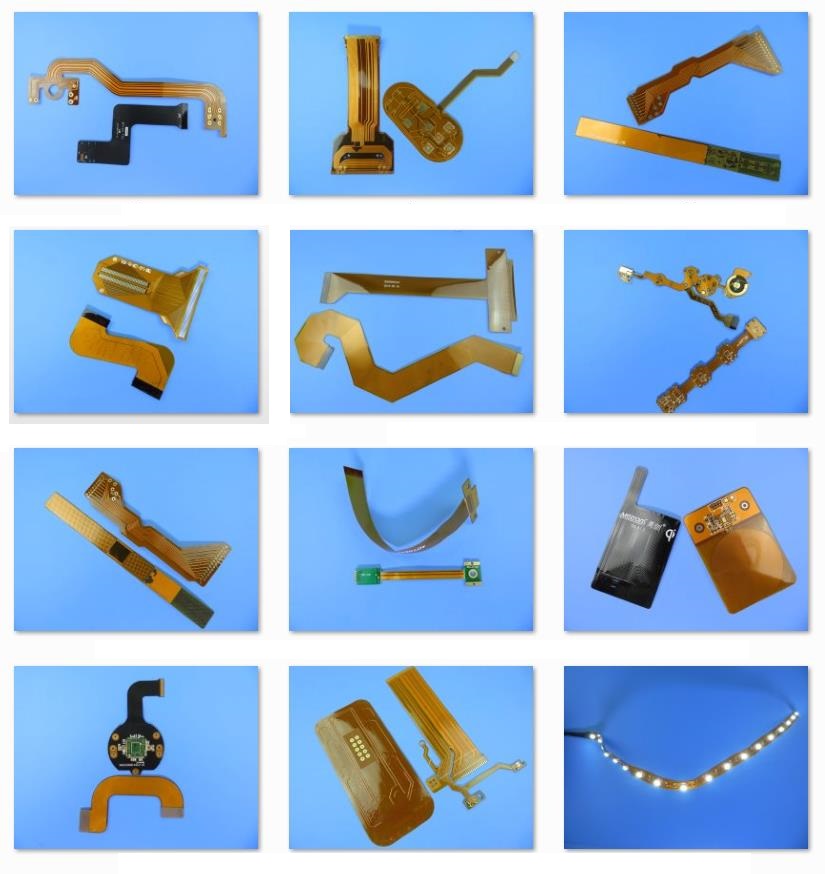

Applications

Thin-film switch, capacitive touch screen / panel, keypad FPC, laser head FPC,General

Purpose LED soft light strip,Telephone receiver / earphone FPC, contact belt of inkjet

Printer, Toy lamp strip,LCD module, instrument panel, flexible flat cable, display backlight

Etc.

FPC

FPC

FPC

Pattern developing

Pattern plating

A breakdown of a flexible circuit shows that it consists of 3 basic elements: copper foil,

Dielectric material and adhesive. most of the manufacturing processes, i.e. Imaging transfer,

Plating and etching, are quite similar to those used when producing plated-through boards.

however, there're differences due to the thin and floppy material used in flexible circuits.

Bicheng Flexible Printed Circuit Capability 2019

| No. | Specifications | Capabilities |

| 1 | Board Type | Single layer, Doulbe layer, Multilayer, Rigid-Flex |

| 2 | Base Material | PI, PET |

| 3 | Copper Weight | 0.5oz, 1oz, 2oz |

| 4 | LED Maximum Size | 250 x 5000mm |

| 5 | General Maximum Size | 250 x 2000mm |

| 6 | Board Thickness | 0.03mm-3.0mm |

| 7 | Thickness Tolerance | 0.03mm |

| 8 | Mininum Drill Hole | 0.05mm |

| 9 | Maximum Drill Hole | 6.5mm |

| 10 | Tolerance of Drill Hole | 0.025mm |

| 11 | Thickness of Hole Wall | 8 um |

| 12 | Minimum Track/Gap of Single Layer Board |

0.025/0.03mm |

| 13 | Minimum Track/Gap of Double Layer and Multilayer Board |

0.03/0.040mm |

| 14 | Etching Tolerance | 0.02mm |

| 15 | Minimum Width of Silk Legend | 0.125mm |

| 16 | Minimum Heigh of Silk Legend | 0.75mm |

| 17 | Distance from Legend to Pad | 0.15mm |

| 18 | Distance from Opening Solder Mask of Drill Coverlay to Track |

0.03mm |

| 19 | Distance from Opening Solder Mask of Punching Coverlay to Track |

0.03mm |

| 20 | Thickness of Immersion Nickel | 100-300u" |

| 21 | Thickness of Immersion Gold | 1-3u" |

| 22 | Thicnkess of Immersion Tin | 150-400u" |

| 23 | Minimum Electrical Testing Pad | 0.2mm |

| 24 | Minimum Tolerance of Outline (Normal Steel Mould Punch) |

0.1mm |

| 25 | Minimum Tolerance of Outline (Precision Steel Mould Punch) |

0.05mm |

| 26 | Mininum Radius of Bevel Angle (Outline) | 0.2mm |

| 27 | Stiffner Material | PI, FR-4, 3M Adhesive, PET, Steel Sheet |

| 28 | RoHs | Yes |

| 29 | Solder Mask Colour | Yellow, White, Black, Green |

Purpose of Flexible Circuits

1) to provide interconnections between printed circuit boards and other components.

2) to serve as three-dimensional substrates for the mounting of SMT components, e.g.,

in

Photographic and video cameras.

3) to establish interconnections capable of withstanding dynamic flexing.

4) to form part of rigid-flex circuit boards.

Advantages

1) Flexibility

2) Volume decreases

3) Weight reduces

4) Consistency of SMD mounting

5) Reliability increases

6) Controllability of electrical design of parameters

7) Tin soldered overall on the FPC end

8) Material optional (PI, PET)

9) Low cost

10) Continuity of processing

Applications

Thin-film switch, capacitive touch screen / panel, keypad FPC, laser head FPC,General

Purpose LED soft light strip,Telephone receiver / earphone FPC, contact belt of inkjet

Printer, Toy lamp strip,LCD module, instrument panel, flexible flat cable, display backlight

Etc.

FPC

FPC

FPC

Pattern developing

Pattern plating