| Surface Finishing: | HASL, Lead Free |

|---|---|

| Board Thickness: | 1.6mm |

| Copper Thickness: | 1 oz |

| Base Material: | 2W/MK dielectric material |

| Brand Name: | Bicheng Enterprise Limited |

| Min. Line Spacing: | 10 mil |

| Min. Line Width: | 12 mil |

| Min. Hole Diameter: | 0.4mm |

| Model Number: | BIC-752-V752 |

| Place of Origin: | China (Mainland) |

| Solder Mask Color: | White |

| Colour of Component Legend: | Black |

| TEST: | 100% Electrical Test prior shipment |

Quick Details

Specifications

Structure of MCPCB

the most common MCPCB construction consists of the following layers:

A metal substrate, typically aluminum. In some applications, a copper substrate is more

Appropriate due to its high thermal conductivity than aluminum (401W/MK versus 237

W/MK) but more expensive.

Epoxy dielectric layer. this is the most important layer in the MCPCB construction as it

Affects the thermal performance, electrical breakdown strength, and, in some cases, the

Solder joint performance of the MCPCB system. the typical thermal conductivity of the

Dielectric layer on a MCPCB is 1W/MK. A higher value is better for good thermal performance.

A thinner dielectric layer is better for thermal performance as well but can negatively impact

the ability of the MCPCB to withstand a high potential test to meet minimum electrical safety

Standards as required in certain lighting markets. the typical dielectric thickness layer is 100m.

Top copper layer. A thicker copper layer improves heat spreading into the PCB but may pose

Challenges for PCB manufacturers when fabricating narrow traces or spaces. A copper thickness

of 1oz (35m) or 2oz (70m) is common.

MCPCB Case: Single Sided Aluminum PCB 2W / MK HASL

LF Applied in LED Lighting

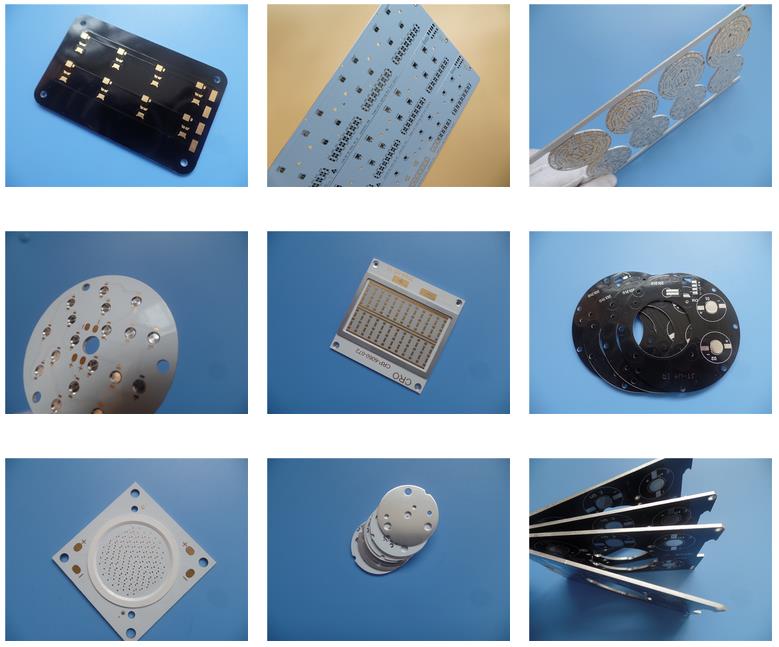

(PCB's are custom-made products, the picture and parameters shown are just for reference)

General description

this is a type of Aluminum PCB for the application of LED Lighting. It's a single layer MCPCB

Board at 1.6 mm thick with 2W/MK thermal conductivity. The aluminum plate is from ITEQ,

Solder mask and silkscreen from Taiyo. It's fabricated per IPC 6012 Class 2 using supplied

Gerber data. Each 10 boards or panels are packed separately.

Features and benefits

SMT process;

Effective heat dissipation reduces the operating temperature of the module and prolongs

the service life;

Power density and reliability are improved up 10%;

Reduce the dependence of heat sinks and other hardware (including thermal interface

Materials),

Reduce the volume of the product;

Reduce the cost of hardware and assembly,

Strict WIP inspection and monitoring as well as working instruction,

Whole fabrication processes are totally controlled;

Meeting your printed circuit board needs from PCB prototyping to mass volume production;

UL recognized and RoHS Directive-compliant;

RoHS materials;

UL conformed

Application

Input-output amplifier,DC/AC converter, automotive ignitor, Street lamp,

Parameter and data sheet

Variety of PCBs

X-ray target shooting

the most common MCPCB construction consists of the following layers:

A metal substrate, typically aluminum. In some applications, a copper substrate is more

Appropriate due to its high thermal conductivity than aluminum (401W/MK versus 237

W/MK) but more expensive.

Epoxy dielectric layer. this is the most important layer in the MCPCB construction as it

Affects the thermal performance, electrical breakdown strength, and, in some cases, the

Solder joint performance of the MCPCB system. the typical thermal conductivity of the

Dielectric layer on a MCPCB is 1W/MK. A higher value is better for good thermal performance.

A thinner dielectric layer is better for thermal performance as well but can negatively impact

the ability of the MCPCB to withstand a high potential test to meet minimum electrical safety

Standards as required in certain lighting markets. the typical dielectric thickness layer is 100m.

Top copper layer. A thicker copper layer improves heat spreading into the PCB but may pose

Challenges for PCB manufacturers when fabricating narrow traces or spaces. A copper thickness

of 1oz (35m) or 2oz (70m) is common.

MCPCB Case: Single Sided Aluminum PCB 2W / MK HASL

LF Applied in LED Lighting

(PCB's are custom-made products, the picture and parameters shown are just for reference)

General description

this is a type of Aluminum PCB for the application of LED Lighting. It's a single layer MCPCB

Board at 1.6 mm thick with 2W/MK thermal conductivity. The aluminum plate is from ITEQ,

Solder mask and silkscreen from Taiyo. It's fabricated per IPC 6012 Class 2 using supplied

Gerber data. Each 10 boards or panels are packed separately.

Features and benefits

SMT process;

Effective heat dissipation reduces the operating temperature of the module and prolongs

the service life;

Power density and reliability are improved up 10%;

Reduce the dependence of heat sinks and other hardware (including thermal interface

Materials),

Reduce the volume of the product;

Reduce the cost of hardware and assembly,

Strict WIP inspection and monitoring as well as working instruction,

Whole fabrication processes are totally controlled;

Meeting your printed circuit board needs from PCB prototyping to mass volume production;

UL recognized and RoHS Directive-compliant;

RoHS materials;

UL conformed

Application

Input-output amplifier,DC/AC converter, automotive ignitor, Street lamp,

Parameter and data sheet

| PCB SIZE | 160 x 83mm=8PCS |

| BOARD TYPE | |

| Number of Layers | Single sided PCB |

| Surface Mount Components | YES |

| through Hole Components | NO |

| LAYER STACKUP | Copper ------- 35um(1oz) |

| 80um 2W/MK dielectric material | |

| Metal base (Aluminum 5052) | |

| TECHNOLOGY | |

| Minimum Trace and Space: | 10mil/12mil |

| Minimum / Maximum Holes: | 0.4/2.5mm |

| Number of Different Holes: | 5 |

| Number of Drill Holes: | 454 |

| Number of Milled Slots: | 22 |

| Number of Internal Cutouts: | 0 |

| Impedance Control | no |

| BOARD MATERIAL | |

| Glass Epoxy: | 2W/MK dielectric material, Aluminum based PCB |

| Final foil external: | 1oz |

| Final foil internal: | 0oz |

| Final height of PCB: | 1.6mm 0.16 |

| PLATING and COATING | |

| Surface Finish | HASL, Lead Free, Sn>=2.54m |

| Solder Mask Apply to: | Top ,12micon Minimum. |

| Solder Mask Color: | White. |

| Solder Mask Type: | LPSM |

| CONTOUR/CUTTING | Routing |

| MARKING | |

| Side of Component Legend | TOP |

| Colour of Component Legend | Black |

| Manufacturer Name or Logo: | Marked on the board in a conductor and leged FREE AREA |

| VIA | Plated through Hole(PTH), via tented. |

| FLAMIBILITY RATING | UL 94-V0 Approval MIN. |

| DIMENSION TOLERANCE | |

| Outline dimension: | 0.0059" (0.15mm) |

| Board plating: | 0.0030" (0.076mm) |

| Drill tolerance: | 0.002" (0.05mm) |

| TEST | 100% Electrical Test prior shipment |

| TYPE of ARTWORK to BE SUPPLIED | Gerber RS-274-X, PCBDOC etc |

| SERVICE AREA | Worldwide, Globally. |

Variety of PCBs

X-ray target shooting