| Surface Finishing: | Hot Air Soldering Leveling(HASL),lead free |

|---|---|

| Board Thickness: | 0.6mm |

| Copper Thickness: | 1 oz |

| Base Material: | 1W/MK dielectric material, MCPCB |

| Brand Name: | Bicheng Enterprise Limited |

| Min. Line Spacing: | 13 mil |

| Min. Line Width: | 14 mil |

| Min. Hole Size: | 1.5mm |

| Model Number: | BIC-753-V753 |

| Place of Origin: | China (Mainland) |

| Solder Mask Color: | Blask |

| Colour of Component Legend: | White |

| TEST: | 100% Electrical Test prior shipment |

Quick Details

Specifications

Double Sided Copper PCB

Double sided copper PCB is a unique metal core PCB characterized by good heat dissipation

and good electrical insulation. the thermal diffusion can be treated effectively in the circuit

Design, which can reduce the operating temperature of the product, improve the power density

and reliability of the product, and prolong the service life of the product.

Key Technology Breakthrough

A) Drill technology

B) Press and hole-filling technology

C) Contour profiling technology

Basic Production Method

1) the primary through holes with larger 0.5mm-1.0mm than the finished holes are drilled

on the pure copper plate, then the finished holes are drilled by the method of pressing and

Filling glue, which provides a prerequisite that there's no short circuit with the pure aluminum

Plate.

2) According to the copper plate lamination program, copper foils are pressed on both sides

of copper plate to complete the basic fabrication of double-sided copper PCB.

3) Other processes can be made as standard double sided PCB.

PCB Services

1) Prototype, small runs and mass production supply

2) Insulated metal substrate (IMS PCB) and Metal core PCB (MCPCB)

3) High thermal conductivity to 3W/MK

4) Proceeding thickness: 0.4-6.0mm thick

5) Plate through hole (PTH20m)

6) BGA (minimum pad 14 mil), Impedance control (+/-10)

7) V-Groove, Punch, CNC mill

8) Long strips, composite aluminum

9) ENIG, HASL, OSP and Immersion tin

MCPCB Case: Double Sided Aluminum PCB 0.6mm Thick

Plated through Hole (PTH)

(PCB's are custom-made products, the picture and parameters shown are just for reference)

General description

this is a type of double sided aluminum PCB for the application of LED Lighting. It's at 0.6mm

Thick with 1W/MK thermal conductivity. The aluminum plate is from ITEQ, Solder mask and

Silkscreen from Taiyo. It's fabricated per IPC 6012 Class 2 using supplied Gerber data. Each

25 panels are packed separately.

Features and benefits

SMT process;

Effective heat dissipation reduces the operating temperature of the module and prolongs

the service life;

Power density and reliability are improved up 10%.

Reduce the dependence of heat sinks and other hardware (including thermal interface

Materials),

Reduce the volume of the product,

Reduce the cost of hardware and assembly,

UL, ISO certified PCB manufacturing factory.

Make delivery on time keeping 98% on-time-delivery rate.

DDU Door to door shipment with competitive shipping cost,

Professional and experienced engineers

Competitive price

on-time service

Application

Balanced amplifier,Communication electronic equipment, Power controller, Industrial and

Mining lamps

Parameter and data sheet

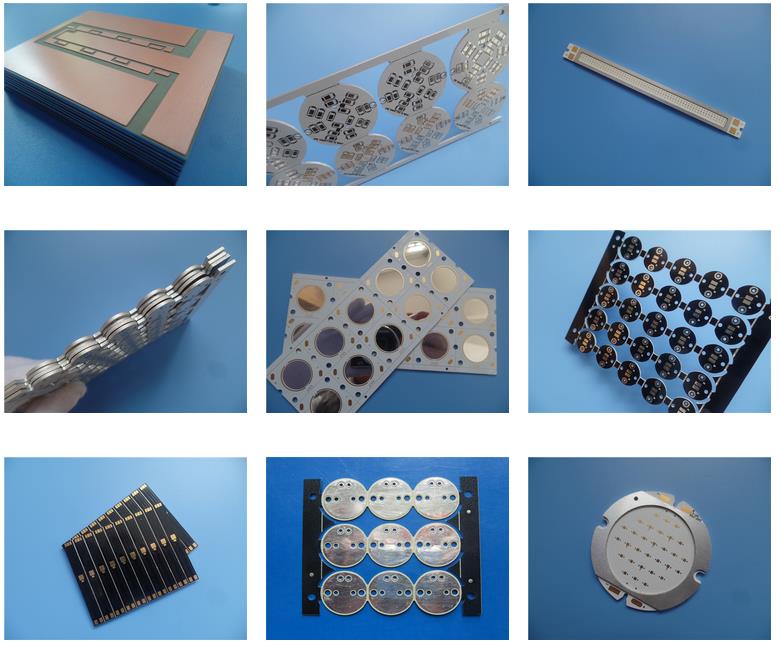

Variety of PCBs

AOI

Double sided copper PCB is a unique metal core PCB characterized by good heat dissipation

and good electrical insulation. the thermal diffusion can be treated effectively in the circuit

Design, which can reduce the operating temperature of the product, improve the power density

and reliability of the product, and prolong the service life of the product.

Key Technology Breakthrough

A) Drill technology

B) Press and hole-filling technology

C) Contour profiling technology

Basic Production Method

1) the primary through holes with larger 0.5mm-1.0mm than the finished holes are drilled

on the pure copper plate, then the finished holes are drilled by the method of pressing and

Filling glue, which provides a prerequisite that there's no short circuit with the pure aluminum

Plate.

2) According to the copper plate lamination program, copper foils are pressed on both sides

of copper plate to complete the basic fabrication of double-sided copper PCB.

3) Other processes can be made as standard double sided PCB.

PCB Services

1) Prototype, small runs and mass production supply

2) Insulated metal substrate (IMS PCB) and Metal core PCB (MCPCB)

3) High thermal conductivity to 3W/MK

4) Proceeding thickness: 0.4-6.0mm thick

5) Plate through hole (PTH20m)

6) BGA (minimum pad 14 mil), Impedance control (+/-10)

7) V-Groove, Punch, CNC mill

8) Long strips, composite aluminum

9) ENIG, HASL, OSP and Immersion tin

MCPCB Case: Double Sided Aluminum PCB 0.6mm Thick

Plated through Hole (PTH)

(PCB's are custom-made products, the picture and parameters shown are just for reference)

General description

this is a type of double sided aluminum PCB for the application of LED Lighting. It's at 0.6mm

Thick with 1W/MK thermal conductivity. The aluminum plate is from ITEQ, Solder mask and

Silkscreen from Taiyo. It's fabricated per IPC 6012 Class 2 using supplied Gerber data. Each

25 panels are packed separately.

Features and benefits

SMT process;

Effective heat dissipation reduces the operating temperature of the module and prolongs

the service life;

Power density and reliability are improved up 10%.

Reduce the dependence of heat sinks and other hardware (including thermal interface

Materials),

Reduce the volume of the product,

Reduce the cost of hardware and assembly,

UL, ISO certified PCB manufacturing factory.

Make delivery on time keeping 98% on-time-delivery rate.

DDU Door to door shipment with competitive shipping cost,

Professional and experienced engineers

Competitive price

on-time service

Application

Balanced amplifier,Communication electronic equipment, Power controller, Industrial and

Mining lamps

Parameter and data sheet

| PCB SIZE | 85 x 91mm=9PCS |

| BOARD TYPE | MCPCB |

| Number of Layers | Double sided PCB, Metal core PCB |

| Surface Mount Components | YES |

| through Hole Components | NO |

| LAYER STACKUP | Copper ------- 35um(1oz)+PLATE |

| 1W/MK dielectric material | |

| Aluminum 1060 | |

| 1W/MK dielectric material | |

| Copper ------- 35um(1oz)+PLATE | |

| TECHNOLOGY | |

| Minimum Trace and Space: | 13mil/14mil |

| Minimum / Maximum Holes: | 1.5/3.3mm |

| Number of Different Holes: | 4 |

| Number of Drill Holes: | 9 |

| Number of Milled Slots: | 0 |

| Number of Internal Cutouts: | 0 |

| Impedance Control | no |

| BOARD MATERIAL | |

| Thermal conductivity | 1W/MK dielectric material, MCPCB |

| Final foil external: | 1oz |

| Final foil internal: | 1oz |

| Final height of PCB: | 0.6mm 0.1 |

| PLATING and COATING | |

| Surface Finish | Hot Air Soldering Leveling(HASL),lead free, Sn>=2.54m |

| Solder Mask Apply to: | Top and Bottom. 12micon Minimum. |

| Solder Mask Color: | Blask |

| Solder Mask Type: | LPSM |

| CONTOUR/CUTTING | Routing |

| MARKING | |

| Side of Component Legend | TOP |

| Colour of Component Legend | White |

| Manufacturer Name or Logo: | Marked on the board in a conductor and leged FREE AREA |

| VIA | via tented. |

| FLAMIBILITY RATING | UL 94-V0 Approval MIN. |

| DIMENSION TOLERANCE | |

| Outline dimension: | 0.0059" (0.15mm) |

| Board plating: | 0.0030" (0.076mm) |

| Drill tolerance: | 0.002" (0.05mm) |

| TEST | 100% Electrical Test prior shipment |

| TYPE of ARTWORK to BE SUPPLIED | Gerber RS-274-X, PCBDOC etc |

| SERVICE AREA | Worldwide, Globally. |

Variety of PCBs

AOI