| Surface Finishing: | Hot Air Soldering Leveling(HASL),lead free |

|---|---|

| Board Thickness: | 1.6mm |

| Copper Thickness: | 1 oz |

| Base Material: | 1.0W/MK 75um dielectric material |

| Brand Name: | Bicheng Enterprise Limited |

| Min. Line Spacing: | 10 mil |

| Min. Line Width: | 10 mil |

| Min. Hole Diameter: | 5.5mm |

| Model Number: | BIC-766-V766 |

| Place of Origin: | China (Mainland) |

| Solder Mask Color: | Super white |

| Colour of Component Legend: | Black |

| TEST: | 100% Electrical Test prior shipment |

Quick Details

Specifications

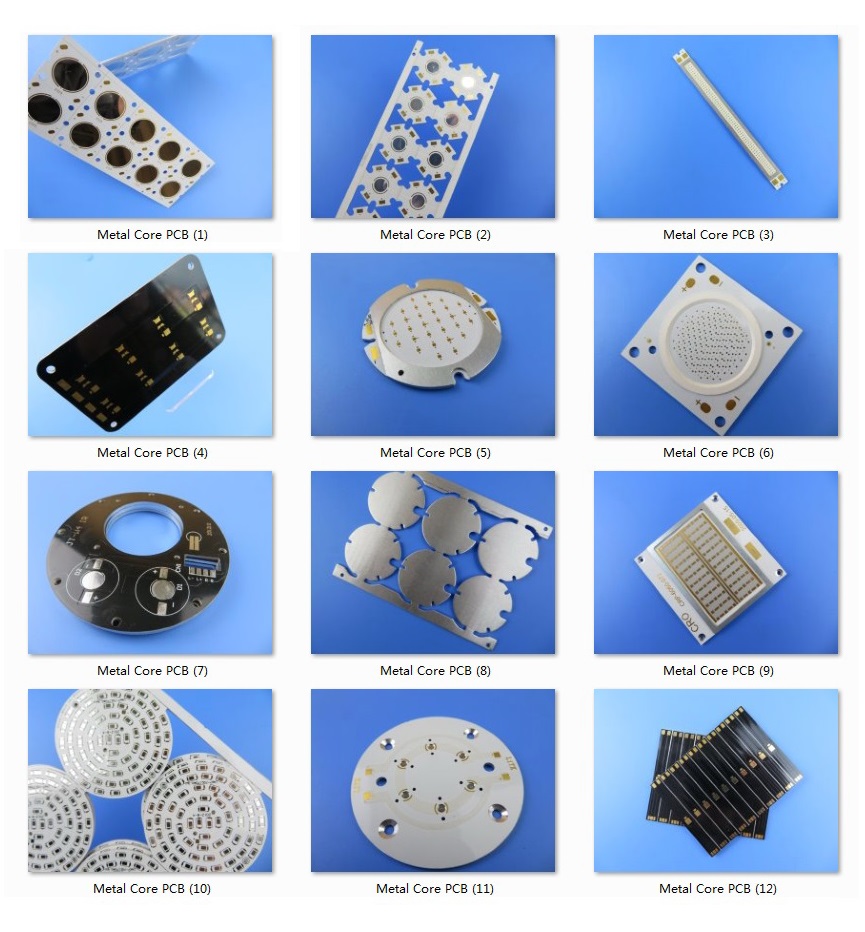

Metal Core PCB

Metal core PCB is thermal management circuit board used in LED lighting which needs fast

Cooling dissipation. the metal core can be aluminum (aluminum core PCB) and copper

(copper core PCB), stainless steel, even iron base.

Advantages of MCPCB

1) Effective heat dissipation reduces the operating temperature of the module and prolongs

the service life;

2) Power density and reliability are improved up 10%;

3) Reduce the dependence of heat sinks and other hardware (including thermal interface

Materials);

4) Reduce the volume of the product;

5) Reduce the cost of hardware and assembly;

6) Optimization combination of power circuit and control circuit;

7) Replace the fragile ceramic substrate and obtain a better mechanical durability;

8) Reduce the operating temperature of the equipment.

Applications

LED lighting, Switch regulator, DC/AC converter, Communication electronic equipment,

A filter electric circuit, Office automation equipment, Motor driver, Motor controller,

Automobile etc.

Solder Mask

Depending on whether light is to be absorbed or reflected, we have green, black and white

Solder mask. White solder mask is commonly used in LED PCB application and we use super

White LED solder mask and no yellowish or brown colour occurs after the bare PCB baking

as well as reflow and wave solder PCB assembly processes.

Aluminum PCB Case: Aluminum PCB Board Built 1W

/ MK for 9W LED Lighting

(PCB's are custom-made products, the picture and parameters shown are just for reference)

General description

this is a type of aluminum PCB for the application of LED Lighting. It's a single layer MCPCB

Board at 1.6 mm thick with 1 W/MK thermal conductivity. The aluminum plate is from ITEQ,

Solder mask and silkscreen from Taiyo. It's fabricated per IPC 6012 Class 2 using supplied

Gerber data. 25 panels are packed for shipment.

Features and benefits

Optimization combination of power circuit and control circuit,

Replace the fragile ceramic substrate and obtain a better mechanical durability,

Effective heat diffusion in the design of the circuit,

Reduce the operating temperature of the equipment,

Improve the power density and reliability of the device,

Prolong the service life of the product,

PCB manufacturing is strictly as per required specifications.

High voltage test, Impedance control test, micro-section, solder-ability test, thermal

Stress test, reliability test, insulation resistance test and ionic contamination test,

Focus on low to medium volume production

Small quantity order is accepted

Delivery on time: >98%

Application

Automobile rear lighting, Radiator, Security system, Gas station lighting,

Parameter and data sheet

Variety of PCBs

Disposal prior to Solder mask

Metal core PCB is thermal management circuit board used in LED lighting which needs fast

Cooling dissipation. the metal core can be aluminum (aluminum core PCB) and copper

(copper core PCB), stainless steel, even iron base.

Advantages of MCPCB

1) Effective heat dissipation reduces the operating temperature of the module and prolongs

the service life;

2) Power density and reliability are improved up 10%;

3) Reduce the dependence of heat sinks and other hardware (including thermal interface

Materials);

4) Reduce the volume of the product;

5) Reduce the cost of hardware and assembly;

6) Optimization combination of power circuit and control circuit;

7) Replace the fragile ceramic substrate and obtain a better mechanical durability;

8) Reduce the operating temperature of the equipment.

Applications

LED lighting, Switch regulator, DC/AC converter, Communication electronic equipment,

A filter electric circuit, Office automation equipment, Motor driver, Motor controller,

Automobile etc.

Solder Mask

Depending on whether light is to be absorbed or reflected, we have green, black and white

Solder mask. White solder mask is commonly used in LED PCB application and we use super

White LED solder mask and no yellowish or brown colour occurs after the bare PCB baking

as well as reflow and wave solder PCB assembly processes.

Aluminum PCB Case: Aluminum PCB Board Built 1W

/ MK for 9W LED Lighting

(PCB's are custom-made products, the picture and parameters shown are just for reference)

General description

this is a type of aluminum PCB for the application of LED Lighting. It's a single layer MCPCB

Board at 1.6 mm thick with 1 W/MK thermal conductivity. The aluminum plate is from ITEQ,

Solder mask and silkscreen from Taiyo. It's fabricated per IPC 6012 Class 2 using supplied

Gerber data. 25 panels are packed for shipment.

Features and benefits

Optimization combination of power circuit and control circuit,

Replace the fragile ceramic substrate and obtain a better mechanical durability,

Effective heat diffusion in the design of the circuit,

Reduce the operating temperature of the equipment,

Improve the power density and reliability of the device,

Prolong the service life of the product,

PCB manufacturing is strictly as per required specifications.

High voltage test, Impedance control test, micro-section, solder-ability test, thermal

Stress test, reliability test, insulation resistance test and ionic contamination test,

Focus on low to medium volume production

Small quantity order is accepted

Delivery on time: >98%

Application

Automobile rear lighting, Radiator, Security system, Gas station lighting,

Parameter and data sheet

| PCB SIZE | 135 x 145mm=4PCS |

| BOARD TYPE | IMS PCB |

| Number of Layers | Single sided PCB, Metal core PCB |

| Surface Mount Components | YES |

| through Hole Components | NO |

| LAYER STACKUP | Copper ------- 35um(1oz) |

| 1.0 W/MK 75um dielectric material | |

| Aluminum base 1060 | |

| TECHNOLOGY | |

| Minimum Trace and Space: | 10mil / 10mil |

| Minimum / Maximum Holes: | 5.5mm |

| Number of Different Holes: | 1 |

| Number of Drill Holes: | 7 |

| Thermal resistance(C/W) | 0.45 |

| Breakdown Voltage(VDC) | 4000 |

| Impedance Control | no |

| BOARD MATERIAL | |

| Thermal conductivity | 1.0W/MK 75um dielectric material |

| Final foil external: | 1oz |

| Final foil internal: | 0oz |

| Final height of PCB: | 1.6mm 0.16 |

| PLATING and COATING | |

| Surface Finish | Hot Air Soldering Leveling(HASL),lead free, Sn>=2.54m |

| Solder Mask Apply to: | Top. 12m Minimum. |

| Solder Mask Color: | Super white, Taiyo PSR400 WT02 |

| Solder Mask Type: | LPSM |

| CONTOUR/CUTTING | Routing |

| MARKING | |

| Side of Component Legend | TOP |

| Colour of Component Legend | Black |

| Manufacturer Name or Logo: | as per requirement |

| VIA | No via |

| FLAMIBILITY RATING | UL 94-V0 Approval MIN. |

| DIMENSION TOLERANCE | |

| Outline dimension: | 0.0059" (0.15mm) |

| Board plating: | 0.0030" (0.076mm) |

| Drill tolerance: | 0.002" (0.05mm) |

| TEST | 100% Electrical Test prior shipment |

| APPLICATION: | High power street LED Light, GPS Tracking Devices Electrical Transformers LED Light Panel Waterproof LED Lights Wireless Router Reviews |

| TYPE of ARTWORK to BE SUPPLIED | Gerber RS-274-X, PCBDOC etc |

| SERVICE AREA | Worldwide, Globally. |

Variety of PCBs

Disposal prior to Solder mask