| Surface Finishing: | OSP |

|---|---|

| Board Thickness: | 1.2mm |

| Copper Thickness: | 280 um (8 oz) |

| Base Material: | Aluminum PCB, MCPCB |

| Brand Name: | Bicheng Enterprise Limited |

| Min. Line Spacing: | 16 mil |

| Min. Line Width: | 14.7 mil |

| Min. Hole Diameter: | no |

| Model Number: | BIC-775-V775 |

| Place of Origin: | China (Mainland) |

| Solder Mask Color: | N/A |

| Color of Silkscreen: | N/A |

| Function: | 100% Pass electrical test |

Quick Details

Specifications

Structure of MCPCB

the most common MCPCB construction consists of the following layers:

1) A metal substrate, typically aluminum. In some applications, a copper substrate is more

Appropriate due to its high thermal conductivity than aluminum (401W/MK versus 237 W/MK)

but more expensive.

2) Epoxy dielectric layer. this is the most important layer in the MCPCB construction as it

Affects the thermal performance, electrical breakdown strength, and, in some cases, the

Solder joint performance of the MCPCB system. the typical thermal conductivity of the

Dielectric layer on a MCPCB is 1W/MK. A higher value is better for good thermal performance.

A thinner dielectric layer is better for thermal performance as well but can negatively impact

the ability of the MCPCB to withstand a high potential test to meet minimum electrical safety

Standards as required in certain lighting markets. the typical dielectric thickness layer is 100m.

3) Top copper layer. A thicker copper layer improves heat spreading into the PCB but may

Pose challenges for PCB manufacturers when fabricating narrow traces or spaces. A copper

Thickness of 1oz (35m) or 2oz (70m) is common.

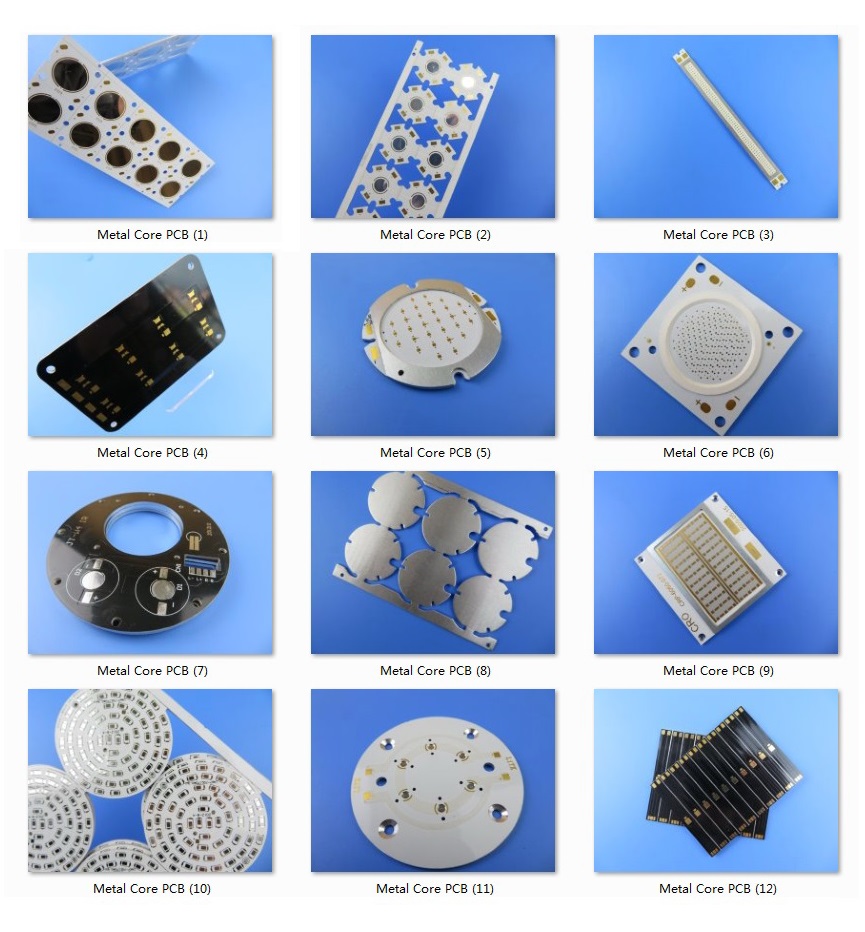

Aluminum PCB Case: Aluminum PCB Circuit Board Built

on 8oz Heavy Copper

(PCB's are custom-made products, the picture and parameters shown are just for reference)

General description

this is a type of heavy copper single sided aluminum PCB board at 1.2mm thick for the

Application of high current and high temperature dissipation. the base laminate is from

ITEQ 9oz Copper. It's fabricated per IPC 6012 Class 2 using supplied Gerber data. Each

20 panel boards are packed separately.

Features and benefits

Optimization combination of power circuit and control circuit,

Replace the fragile ceramic substrate and obtain a better mechanical durability,

Effective heat diffusion in the design of the circuit,

Reduce the operating temperature of the equipment,

Improve the power density and reliability of the device,

Prolong the service life of the product,

Whole fabrication processes are totally controlled.

100% tests inclusive of electrical test and AOI inspection, thermal stress test,

Reliability test, insulation resistance test and ionic contamination test

RoHS materials

Focus on low to medium volume production

Small quantity order is accepted

Application

Downlight, Automatic safety control system, DC/AC converter, power amplifier,

Parameter and data sheet

Variety of PCBs

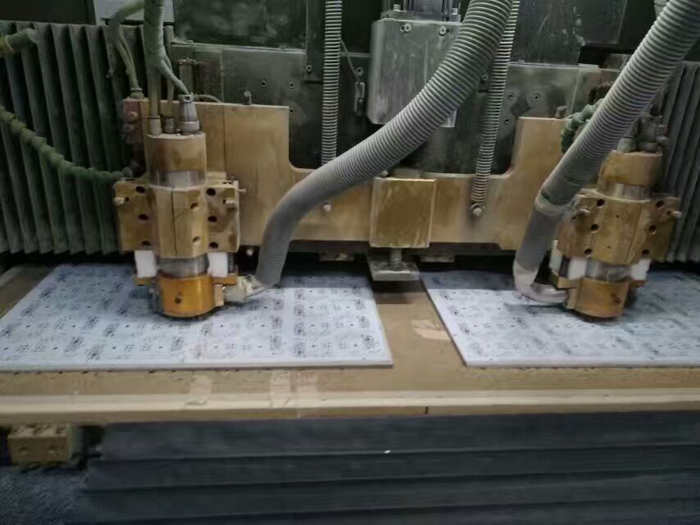

Aluminum drill

the most common MCPCB construction consists of the following layers:

1) A metal substrate, typically aluminum. In some applications, a copper substrate is more

Appropriate due to its high thermal conductivity than aluminum (401W/MK versus 237 W/MK)

but more expensive.

2) Epoxy dielectric layer. this is the most important layer in the MCPCB construction as it

Affects the thermal performance, electrical breakdown strength, and, in some cases, the

Solder joint performance of the MCPCB system. the typical thermal conductivity of the

Dielectric layer on a MCPCB is 1W/MK. A higher value is better for good thermal performance.

A thinner dielectric layer is better for thermal performance as well but can negatively impact

the ability of the MCPCB to withstand a high potential test to meet minimum electrical safety

Standards as required in certain lighting markets. the typical dielectric thickness layer is 100m.

3) Top copper layer. A thicker copper layer improves heat spreading into the PCB but may

Pose challenges for PCB manufacturers when fabricating narrow traces or spaces. A copper

Thickness of 1oz (35m) or 2oz (70m) is common.

Aluminum PCB Case: Aluminum PCB Circuit Board Built

on 8oz Heavy Copper

(PCB's are custom-made products, the picture and parameters shown are just for reference)

General description

this is a type of heavy copper single sided aluminum PCB board at 1.2mm thick for the

Application of high current and high temperature dissipation. the base laminate is from

ITEQ 9oz Copper. It's fabricated per IPC 6012 Class 2 using supplied Gerber data. Each

20 panel boards are packed separately.

Features and benefits

Optimization combination of power circuit and control circuit,

Replace the fragile ceramic substrate and obtain a better mechanical durability,

Effective heat diffusion in the design of the circuit,

Reduce the operating temperature of the equipment,

Improve the power density and reliability of the device,

Prolong the service life of the product,

Whole fabrication processes are totally controlled.

100% tests inclusive of electrical test and AOI inspection, thermal stress test,

Reliability test, insulation resistance test and ionic contamination test

RoHS materials

Focus on low to medium volume production

Small quantity order is accepted

Application

Downlight, Automatic safety control system, DC/AC converter, power amplifier,

Parameter and data sheet

| PCB Size | 90 X 70mm = 1 PCS |

| Number of Layers | 1 |

| Board Type | Single Sided PCB |

| Board Thickness | 1.20 mm +/-0.1 |

| Board Material | Aluminum PCB, MCPCB |

| Board Material Supplier | ITEQ |

| Tg Value of Board Material | 150 |

| PTH Cu thickness | N/A |

| Inner Iayer Cu thicknes | N/A |

| Surface Cu thickness | 280 um (8 oz) |

| Solder Mask Type and Model No. | N/A |

| Solder Mask Supplier | N/A |

| Solder Mask Colour | N/A |

| Number of Solder Masks | N/A |

| Thickness of Solder Mask | N/A |

| Type of Silkscreen Ink | N/A |

| Supplier of Silkscreen | N/A |

| Color of Silkscreen | N/A |

| Number of Silkscreen | N/A |

| Mininum Trace (mil) | 16 mil |

| Minimum Gap(mil) | 14.7 mil |

| Surface Finish | OSP |

| RoHS Required | Yes |

| Warpage | 0.14% |

| Thermal Shock Test | Pass, 2885,10 seconds, 3 cycles.No delamination, No blistering. |

| Solderablity Test | Pass, 2555,5 seconds Wetting Area Least 95% |

| Function | 100% Pass electrical test |

| Workmanship | Compliance with IPC-A-600H & IPC-6012C Class 2 |

Variety of PCBs

Aluminum drill