| Surface Finishing: | Immersion gold |

|---|---|

| Board Thickness: | 2.0mm |

| Copper Thickness: | 35-105um |

| Base Material: | Thermoelectric Separation (398 W/MK) |

| Brand Name: | Bicheng Enterprise Limited |

| Min. Line Spacing: | N/A |

| Min. Line Width: | N/A |

| Min. Hole Diameter: | N/A |

| Model Number: | BIC-0801-V801 |

| Place of Origin: | China (Mainland) |

| Solder mask Colour: | Black |

| Silkscreen Color: | White |

| E-test: | 100% open-short circuit test, AOI Test |

Quick Details

Specifications

Copper Based PCB

Copper core PCB is one of the most expensive metal substrates, and its thermal conductivity

Is many times better than that of aluminum and iron substrates. It is suitable for high frequency

Circuits, high and low temperature changing regions and the heat dissipation and building

Decoration industries of precision communication equipment.

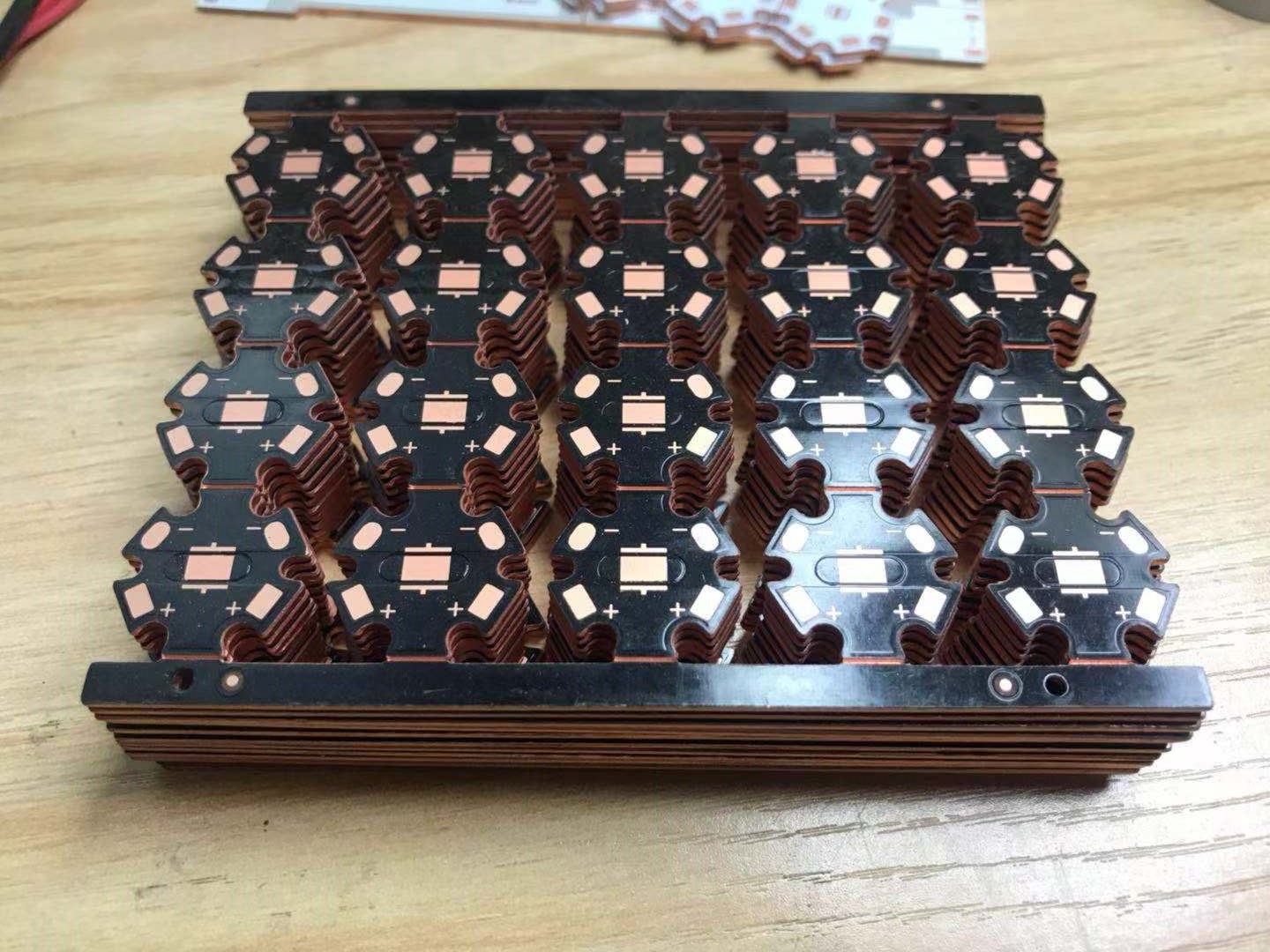

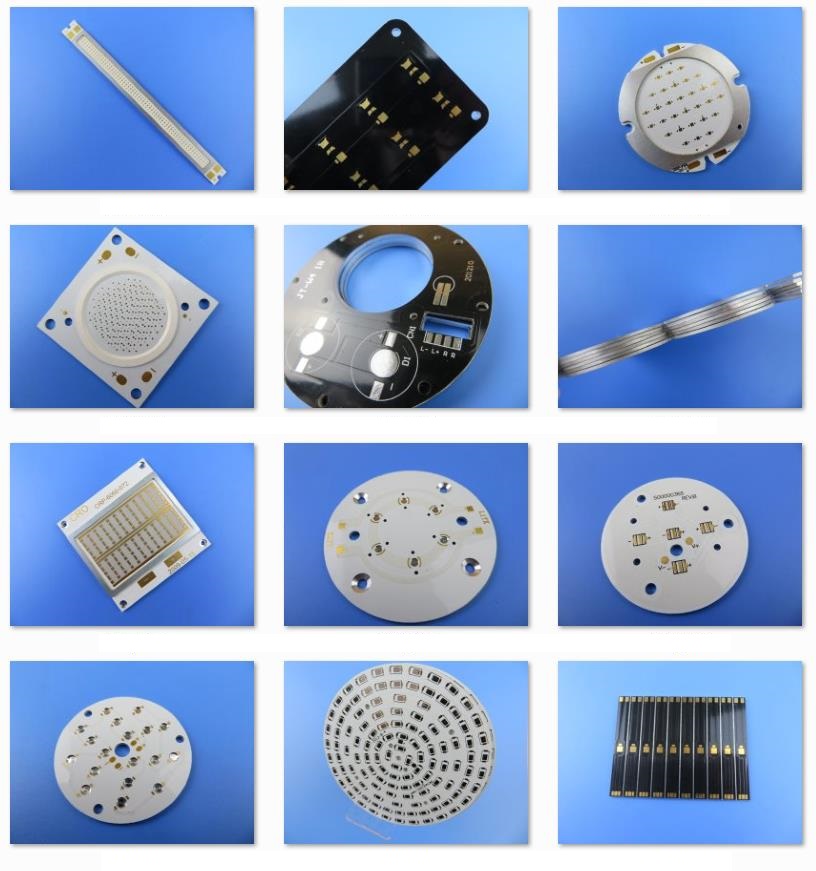

Metal Core PCB Case: Single Sided Copper Core PCB

with Immersion Gold

(PCB's are custom-made products, the picture and parameters shown are just for reference)

General profile

Board thickness: 2.0mm

Copper weight: 35-105um

Production technology: Exposure technology

Surface finish: Immersion gold

Voltage-withstand: AC2500-4000V

Thermal conductivity: Thermoelectric Separation (398 W/MK)

Solder mask: White

E-test: 100% open-short circuit test, AOI Test

Lead time: 2 weeks

Contour: Punch +CNC mill

Metal Core PCB Capability 2019

the circuit layer of copper substrate is required to have a large current-carrying capacity,

so a thick copper foil should be used, the thickness of which is generally 35 m ~ 280 m;

Thermal insulation layer is the core technology of copper substrate too. The core thermal

Conductivity is composed of aluminum trioxide and silicon powder and polymer filled with

Epoxy resin, the thermal resistance is low (0.15), viscoelasticity is excellent, and it has the

Ability to resist thermal aging. It is able to withstand mechanical and thermal stress.

Metal base is the support member of copper PCB. It is required to have high thermal

Conductivity, generally copper sheet is used because copper can provide better thermal

Conductivity, suitable for drilling, punching, shearing and cutting and other conventional

Machining.

Thermoelectric Separation

A) the heat derived from LED is directly transfer through copper

B) Thermal conductivity is higher at 380 W/MK

C) Maximum power output 80 watt

Copper Core PCB

1) Single sided, double sided.

2) Insulated metal substrate (IMS PCB) and Metal core PCB (MCPCB)

3) V-Groove, Punch, CNC milling

4) ENIG, HASL, OSP and Immersion tin

5) Solder mask: Black, White and Green

MCPCB

MCPCB

Automatic sticking film machine

Copper core PCB is one of the most expensive metal substrates, and its thermal conductivity

Is many times better than that of aluminum and iron substrates. It is suitable for high frequency

Circuits, high and low temperature changing regions and the heat dissipation and building

Decoration industries of precision communication equipment.

Metal Core PCB Case: Single Sided Copper Core PCB

with Immersion Gold

(PCB's are custom-made products, the picture and parameters shown are just for reference)

General profile

Board thickness: 2.0mm

Copper weight: 35-105um

Production technology: Exposure technology

Surface finish: Immersion gold

Voltage-withstand: AC2500-4000V

Thermal conductivity: Thermoelectric Separation (398 W/MK)

Solder mask: White

E-test: 100% open-short circuit test, AOI Test

Lead time: 2 weeks

Contour: Punch +CNC mill

Metal Core PCB Capability 2019

| NO. | Parameter | Value |

| 1 | Type of Metal Core | Aluminum, Copper, Iron |

| 2 | Model of Metal Core | A1100, A5052, A6061, A6063, C1100 |

| 3 | Surface Finish | HASL, Immersion Gold, Immersion Silver, OSP |

| 4 | Thickness of Surface plating | HASL: Sn>2.54M, ENIG: Au 0.025-0.1m, Ni 2.5-5m |

| 5 | Layer Count | 1-4 Layers |

| 6 | Maximum of Board Size | 23" x 46" (584mm1168mm) |

| 7 | Mininum of Board Size | 0.1969" x 0.1969" (5mm5mm) |

| 8 | Board Thickness | 0.0157" x 0.2362" (0.4-6.0mm) |

| 9 | Copper Thickness | 0.5OZ(17.5m),1OZ(35m),2OZ(70m) 3OZ(105m),4OZ(140m) to 10oz (350m) |

| 10 | Minimum Track Width | 5mil (0.127mm) |

| 11 | Minimum Space | 5mil (0.127mm) |

| 12 | Minimum Hole Size | 0.0197" (0.5mm) |

| 13 | Maximum Hole Size | No limit |

| 14 | Minimum Holes Punched | PCB thickness <1.0mm: 0.0394" (1.0mm) |

| PCB thikness 1.2-3.0mm: 0.0591" (1.5mm) | ||

| 15 | PTH Wall Thickness | >20m |

| 16 | Tolerance of PTH | 0.00295" (0.075mm) |

| 17 | Tolerance of NPTH | 0.00197" (0.05mm) |

| 18 | Deviation of Hole Position | 0.00394" (0.10mm) |

| 19 | Outline Tolerance | Routing: 0.00394" (0.1mm) |

| Punching: 0.00591" (0.15mm) | ||

| 20 | Angle of V-cut | 30, 45, 60 |

| 21 | V-cut Size | 0.1969" x 47.24" (5mm1200mm) |

| 22 | Thickness of V-cut Board | 0.0236" x 0.1181" (0.6-3mm) |

| 23 | Tolerance of V-cut Angle | 5 |

| 24 | V-CUT Verticality | 0.0059" (0.15mm) |

| 25 | Minimum Square Slots Punched | PCB thickness < 1.0mm: 0.0315" x 0.0315" (0.8 x 0.8mm) |

| PCB thickness 1.2-3.0mm: 0.0394" x 0.0394" (1.0 x 1.0mm) | ||

| 26 | Minimum BGA PAD | 0.01378" (0.35mm) |

| 27 | Minimum Width of Solder Mask Bridge. | 8mil (0.2032mm) |

| 28 | Minimum Thickness of Solder Mask | >13M (0.013mm) |

| 29 | Insulation Resistance | 1012Normal |

| 30 | Peel-off Strength | 2.2N/mm |

| 31 | Solder float | 260 3min |

| 32 | E-test Voltage | 50-250V |

| 33 | Thermal Conductivity | 0.8-8W/M.K |

| 34 | Warp or Twist | 0.5% |

| 35 | Flammability | FV-0 |

| 36 | Minimum Height of Component indicator | 0.0059"(0.15mm) |

| 37 | Minimum Open Solder Mask on Pad | 0.000394" (0.01mm) |

the circuit layer of copper substrate is required to have a large current-carrying capacity,

so a thick copper foil should be used, the thickness of which is generally 35 m ~ 280 m;

Thermal insulation layer is the core technology of copper substrate too. The core thermal

Conductivity is composed of aluminum trioxide and silicon powder and polymer filled with

Epoxy resin, the thermal resistance is low (0.15), viscoelasticity is excellent, and it has the

Ability to resist thermal aging. It is able to withstand mechanical and thermal stress.

Metal base is the support member of copper PCB. It is required to have high thermal

Conductivity, generally copper sheet is used because copper can provide better thermal

Conductivity, suitable for drilling, punching, shearing and cutting and other conventional

Machining.

Thermoelectric Separation

A) the heat derived from LED is directly transfer through copper

B) Thermal conductivity is higher at 380 W/MK

C) Maximum power output 80 watt

Copper Core PCB

1) Single sided, double sided.

2) Insulated metal substrate (IMS PCB) and Metal core PCB (MCPCB)

3) V-Groove, Punch, CNC milling

4) ENIG, HASL, OSP and Immersion tin

5) Solder mask: Black, White and Green

MCPCB

MCPCB

Automatic sticking film machine