| Surface Finishing: | HASL |

|---|---|

| Board Thickness: | 1.2mm |

| Copper Thickness: | 1.0 OZ |

| Base Material: | 1W/MK thermal conductivity |

| Brand Name: | Bicheng Enterprise Limited |

| Min. Line Spacing: | N/A |

| Min. Line Width: | N/A |

| Min. Hole Diameter: | N/A |

| Model Number: | BIC-804-V804 |

| Place of Origin: | China (Mainland) |

| Solder mask Colour: | White |

| Silkscreen Color: | Black |

| TEST: | 100% Electrical Test prior shipment |

Quick Details

Specifications

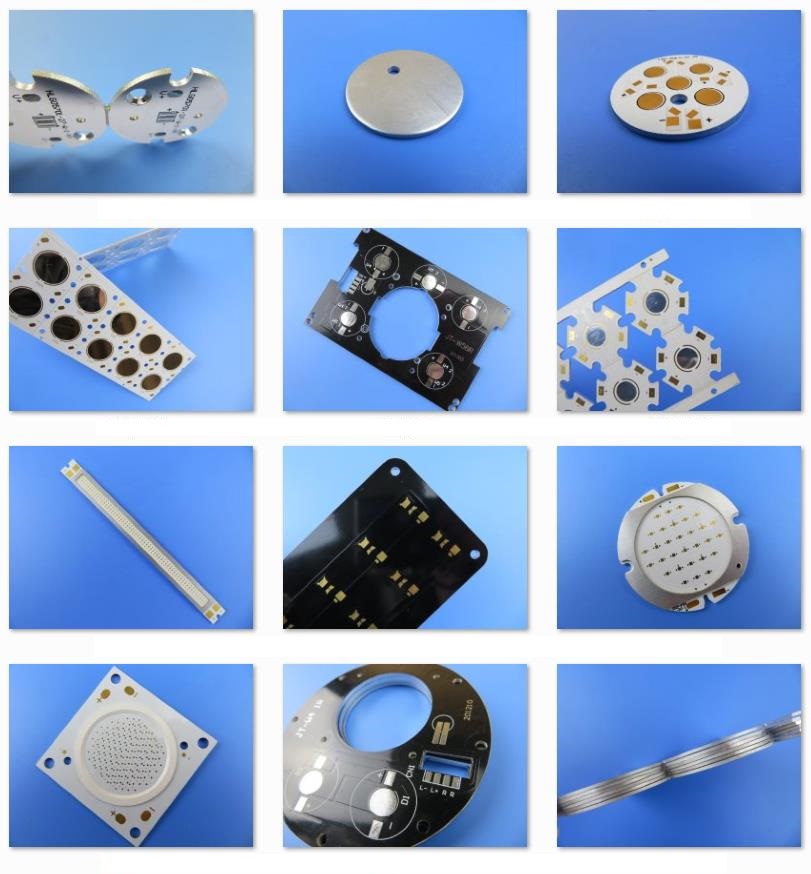

COB Mirror Aluminum PCB | Metal Core Circuit Board

(PCB's are custom-made products, the picture and parameters shown are just for reference)

Mirror Aluminum PCB

the mirror aluminum PCB is a substrate which is pressed together with BT material circuit

Layer and aluminum substrate with silver particles. It is the most suitable raw material for

COB packaging.

Advantages

Good heat dissipation: the mirror silver aluminum substrate adopts thermoelectric separation

Technology, and the thermal conductivity of ordinary aluminum PCB with insulating layer is

1W/MK to 3W/MK. the thermal conductivity of mirror aluminum PCB reaches higher 137W/MK,

Which greatly improves the heat dissipation of the chip.

High light efficiency: the reflectivity of the ordinary gold aluminum PCB is 80%, the reflectivity

of the cup hole aluminum PCB is 85%, the reflectivity of the silver plated aluminum PCB is 95%,

and the reflectivity of the mirror silver aluminum PCB is 98%. the mirror silver aluminum PCB

Can make the light of the chip better excited.

PCB Services

1) Prototype, small runs and mass production supply

2) V-Groove, Punch, CNC mill

3) ENIG, HASL, OSP and Immersion tin

4) No MOQ

5) Door to door shipping service

Metal Core PCB Capability 2019

MCPCB

MCPCB

Developing line

(PCB's are custom-made products, the picture and parameters shown are just for reference)

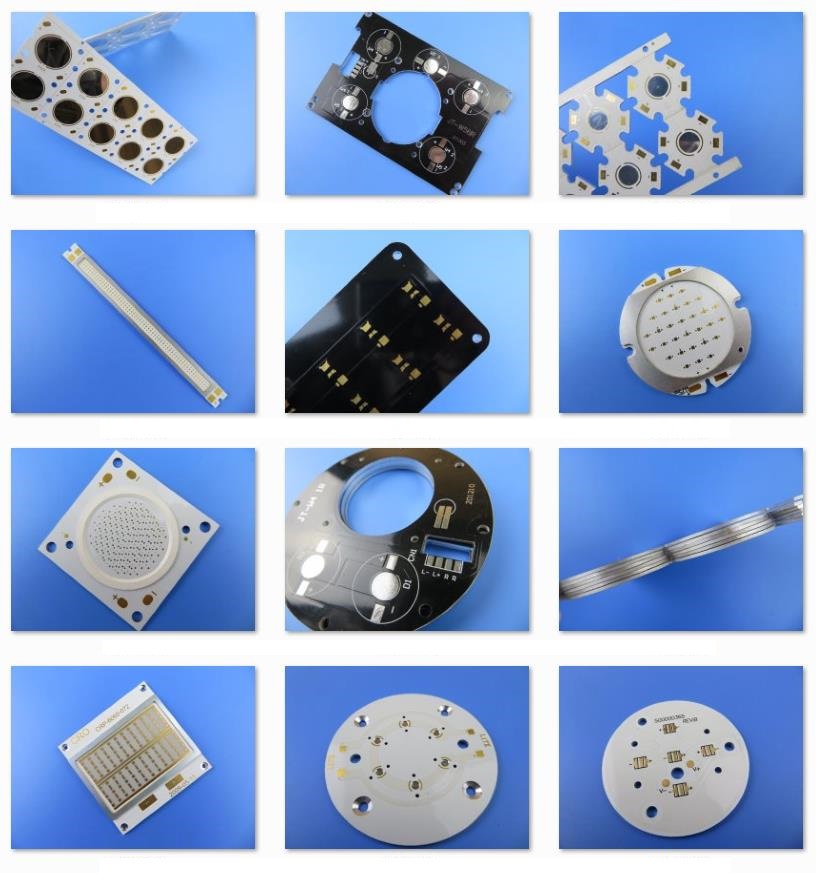

Mirror Aluminum PCB

the mirror aluminum PCB is a substrate which is pressed together with BT material circuit

Layer and aluminum substrate with silver particles. It is the most suitable raw material for

COB packaging.

Advantages

Good heat dissipation: the mirror silver aluminum substrate adopts thermoelectric separation

Technology, and the thermal conductivity of ordinary aluminum PCB with insulating layer is

1W/MK to 3W/MK. the thermal conductivity of mirror aluminum PCB reaches higher 137W/MK,

Which greatly improves the heat dissipation of the chip.

High light efficiency: the reflectivity of the ordinary gold aluminum PCB is 80%, the reflectivity

of the cup hole aluminum PCB is 85%, the reflectivity of the silver plated aluminum PCB is 95%,

and the reflectivity of the mirror silver aluminum PCB is 98%. the mirror silver aluminum PCB

Can make the light of the chip better excited.

PCB Services

1) Prototype, small runs and mass production supply

2) V-Groove, Punch, CNC mill

3) ENIG, HASL, OSP and Immersion tin

4) No MOQ

5) Door to door shipping service

Metal Core PCB Capability 2019

| NO. | Parameter | Value |

| 1 | Type of Metal Core | Aluminum, Copper, Iron |

| 2 | Model of Metal Core | A1100, A5052, A6061, A6063, C1100 |

| 3 | Surface Finish | HASL, Immersion Gold, Immersion Silver, OSP |

| 4 | Thickness of Surface plating | HASL: Sn>2.54M, ENIG: Au 0.025-0.1m, Ni 2.5-5m |

| 5 | Layer Count | 1-4 Layers |

| 6 | Maximum of Board Size | 23" x 46" (584mm1168mm) |

| 7 | Mininum of Board Size | 0.1969" x 0.1969" (5mm5mm) |

| 8 | Board Thickness | 0.0157" x 0.2362" (0.4-6.0mm) |

| 9 | Copper Thickness | 0.5OZ(17.5m),1OZ(35m),2OZ(70m) 3OZ(105m),4OZ(140m) to 10oz (350m) |

| 10 | Minimum Track Width | 5mil (0.127mm) |

| 11 | Minimum Space | 5mil (0.127mm) |

| 12 | Minimum Hole Size | 0.0197" (0.5mm) |

| 13 | Maximum Hole Size | No limit |

| 14 | Minimum Holes Punched | PCB thickness <1.0mm: 0.0394" (1.0mm) |

| PCB thikness 1.2-3.0mm: 0.0591" (1.5mm) | ||

| 15 | PTH Wall Thickness | >20m |

| 16 | Tolerance of PTH | 0.00295" (0.075mm) |

| 17 | Tolerance of NPTH | 0.00197" (0.05mm) |

| 18 | Deviation of Hole Position | 0.00394" (0.10mm) |

| 19 | Outline Tolerance | Routing: 0.00394" (0.1mm) |

| Punching: 0.00591" (0.15mm) | ||

| 20 | Angle of V-cut | 30, 45, 60 |

| 21 | V-cut Size | 0.1969" x 47.24" (5mm1200mm) |

| 22 | Thickness of V-cut Board | 0.0236" x 0.1181" (0.6-3mm) |

| 23 | Tolerance of V-cut Angle | 5 |

| 24 | V-CUT Verticality | 0.0059" (0.15mm) |

| 25 | Minimum Square Slots Punched | PCB thickness < 1.0mm: 0.0315" x 0.0315" (0.8 x 0.8mm) |

| PCB thickness 1.2-3.0mm: 0.0394" x 0.0394" (1.0 x 1.0mm) | ||

| 26 | Minimum BGA PAD | 0.01378" (0.35mm) |

| 27 | Minimum Width of Solder Mask Bridge. | 8mil (0.2032mm) |

| 28 | Minimum Thickness of Solder Mask | >13M (0.013mm) |

| 29 | Insulation Resistance | 1012Normal |

| 30 | Peel-off Strength | 2.2N/mm |

| 31 | Solder float | 260 3min |

| 32 | E-test Voltage | 50-250V |

| 33 | Thermal Conductivity | 0.8-8W/M.K |

| 34 | Warp or Twist | 0.5% |

| 35 | Flammability | FV-0 |

| 36 | Minimum Height of Component indicator | 0.0059"(0.15mm) |

| 37 | Minimum Open Solder Mask on Pad | 0.000394" (0.01mm) |

MCPCB

MCPCB

Developing line