| After-sales Service Provided: | Overseas third-party support available |

|---|---|

| Clamping Force: | 3500N |

| Brand Name: | SUNBUN |

| Style: | Horizontal |

| Condition: | New |

| Certification: | CE UL ISO9001 ISO14001 |

| Power(W): | 37 KW |

| Opening Stroke: | 700 mm |

| Injection Rate: | 403 cm3/s |

| Injection Weight: | 1306 |

| Automatic: | Yes |

| Plastic Type: | Thermoplastic |

| Place of Origin: | China (Mainland) |

| Model Number: | SK350 |

| Type: | Preform Injection |

Quick Details

Specifications

Brand:Sunbun

Founded:2002 Year

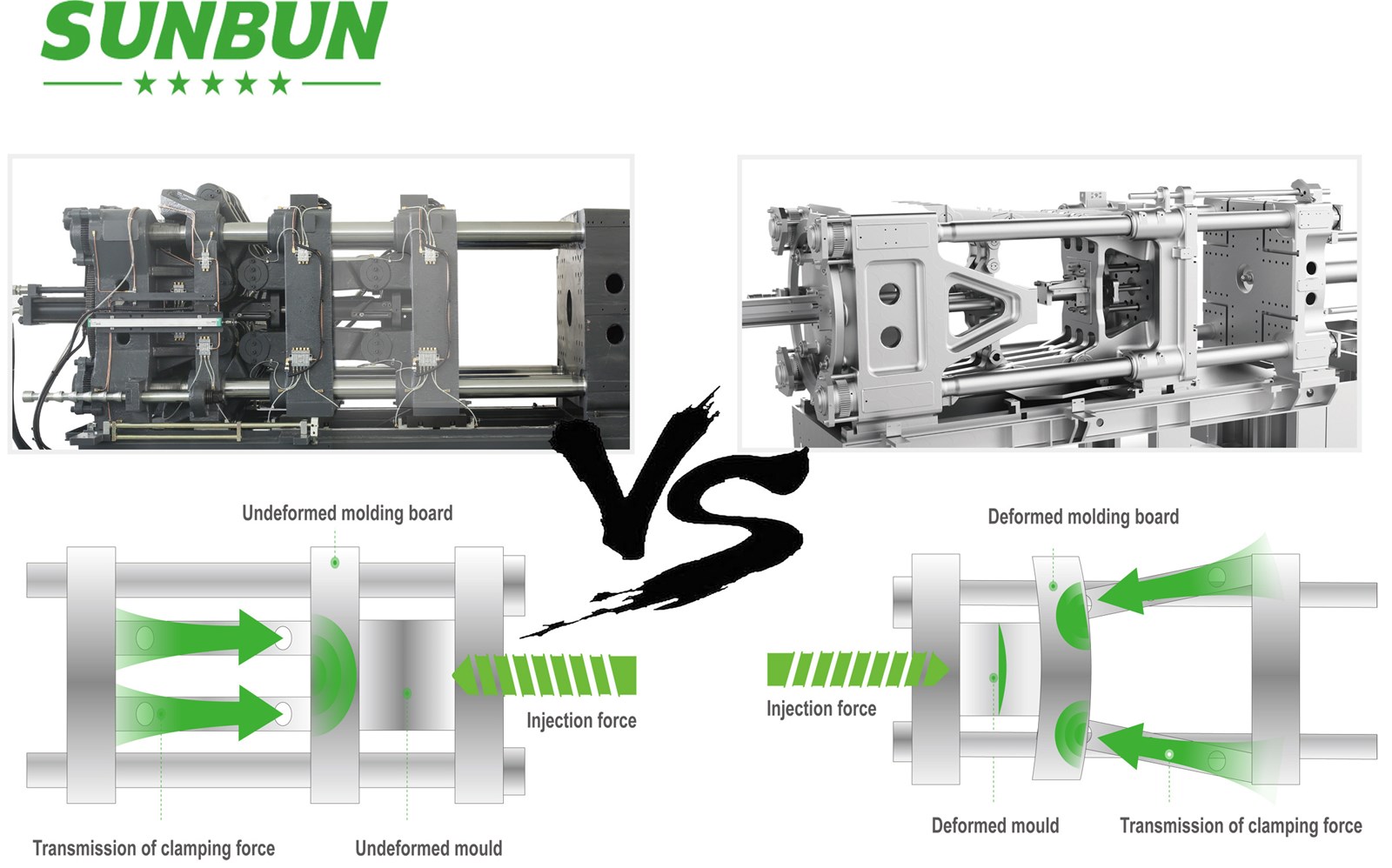

Structure:Central locking stucture / Central clamping sturcture (China only 2 factory )

Production condition:2000 set 2018 years

Tonnage:140T-2800T

Series:SK Series High speed high precision machine

Biggest live project:1800T /2500T

Advantage of Central locking sturcture (sales points)

1, 100% clampping force use ratio.10%-20% higher than tradtional one

2, Less fins on the finished products

3, 2%-6% raw material saving on the production (deeper cavity more, save more material)

4, effective production for the mold.Mold board and pull rod

5, Open stroke 10%-20% longer than tradtional one

6, Less deformation after cooling

7, FB:

Shortl spacking.......

1, Bigger clampping force, Use smaller machine make bigger productes

2, Bigger Open stroke, Very suit for deep cavity product

Founded:2002 Year

Structure:Central locking stucture / Central clamping sturcture (China only 2 factory )

Production condition:2000 set 2018 years

Tonnage:140T-2800T

Series:SK Series High speed high precision machine

Biggest live project:1800T /2500T

Advantage of Central locking sturcture (sales points)

1, 100% clampping force use ratio.10%-20% higher than tradtional one

2, Less fins on the finished products

3, 2%-6% raw material saving on the production (deeper cavity more, save more material)

4, effective production for the mold.Mold board and pull rod

5, Open stroke 10%-20% longer than tradtional one

6, Less deformation after cooling

7, FB:

Shortl spacking.......

1, Bigger clampping force, Use smaller machine make bigger productes

2, Bigger Open stroke, Very suit for deep cavity product

| Inject type | Unit | SK350/C1900 | |||||||

| Screw type | A | B | C | D | |||||

| Screw dia | Mm | 60 | 65 | 70 | 75 | ||||

| Screw dia ratio | L/D | 22.5 | 21 | 21.5 | 20 | ||||

| Injection volume | Cm3 | 918 | 1078 | 1250 | 1435 | ||||

| Injection volume (ps) | G | 835 | 981 | 1138 | 1306 | ||||

| Max injection rate to air | Cm3/s | 258 | 302 | 350 | 403 | ||||

| Injection pressure | Mpa | 206 | 176 | 152 | 132 | ||||

| Injection stroke | Mm | 325 | |||||||

| Max injection speed | Mm/s | 92 | |||||||

| Screw max speed | R/min | 182 | |||||||

| Clamping force | Kn | 3500 | |||||||

| Open stroke | mm | 700 | |||||||

| Bar distance | Mmxmm | 713X660 | |||||||

| Max mold | Mm | 730 | |||||||

| Min mold | Mm | 330 | |||||||

| Ejector stroke | Mm | 190 | |||||||

| Ejector force forward | Kn | 113 | |||||||

| Ejector force backard | Kn | 82 | |||||||

| Thimble qty | Pcs | 1+12 | |||||||

| System pressure | Mpa | 16 | |||||||

| Motor power | Kw | 37 | |||||||

| Heater power | Kw | 24.95/28.55 | |||||||

| Tem control zone qty | Pcs | 1+5 | |||||||

| Bucket capacity | Kg | 50 | |||||||

| Oil tank capacity | L | 520 | |||||||

| Size | M | 7.1X1.75X2.2 | |||||||

| Weight | T | 13 | |||||||