| Application: | Laser Cutting |

|---|---|

| Certification: | CE,ISO,SGS |

| Brand Name: | Pioneer Laser |

| Graphic Format Supported: | DST,DWG,DXF,DXP |

| Applicable Material: | Metal |

| Laser Type: | Fiber Laser |

| After-sales Service Provided: | Engineers available to service machinery overseas |

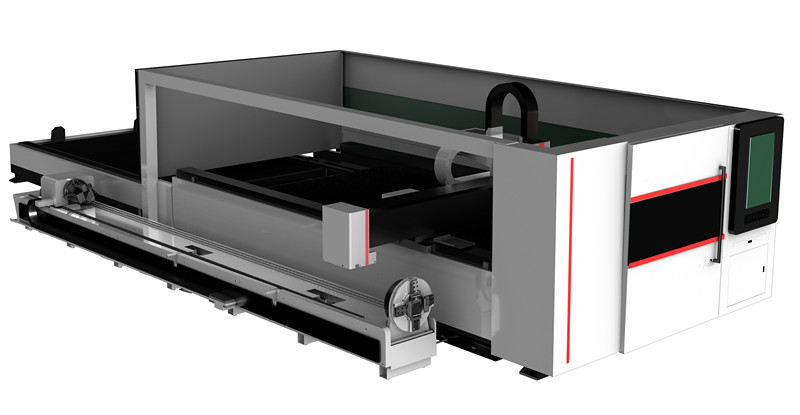

| Model Number: | PFG-3015D |

| Place of Origin: | China (Mainland) |

| Control Software: | CypCut |

| Cooling Mode: | Water Cooling |

| CNC or Not: | Yes |

| Cutting Speed: | 100m/min |

| Cutting Area: | 1500mmx3000mm |

| Cutting Thickness: | 25mm |

| Condition: | New |

| Control system: | CypCut |

| Laser power source: | IPG |

| Laser head: | Precitec |

| Servo motor: | Yaskawa |

| Rack&pinion: | YCC |

| Linear slider: | Hiwin |

| Water cooling: | Tongfei |

| Positioning accuracy: | &plus0.03mm |

| Accleration: | 2G |

Quick Details

Specifications

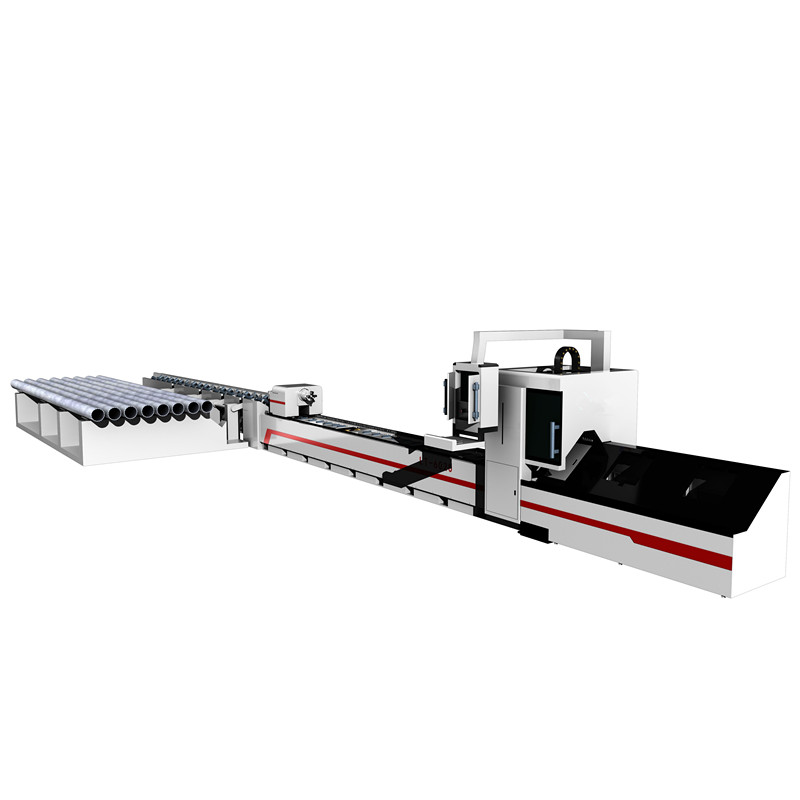

Multiple Use CNC Tube&Plate Steel Laser Cutter for Tube Processing

Brief CNC Laser Cutter Introduction

this PFG-3015D double-platform laser cutting machine is a fully enclosed laser cutting machine combining with tube cutting function.Full enclosure design can not only reduce the damage of laser radiation to workers, but also effectively prevent metal debris splash from causing damage to operators.the maximum power of this metal laser cutting machine can reach 20000W. It can be used for cutting, punching and engraving various precision parts and machine panel.the metal crafts processed by the optical fiber laser cutting machine have little heat effect on the cutting seam and generally do not need secondary processing.

Application Materials

Fiber Laser Cutting Equipment is suitable for metal cutting like Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

Application Industries

Machines are widely used in manufacture Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

Main Configuration

Technical Parameter

the features of a laser cutting machine

1. High rigidity heavy chassis, reducing the vibration generated during the high-speed cutting process.

2.Gantry double-drive structure, with imported Germany rack & gear transmission system, which improves the production efficiency.

3. High-performance cast aluminum guide rail, after infinite analysis, which accelerates the circular arc cutting speed.

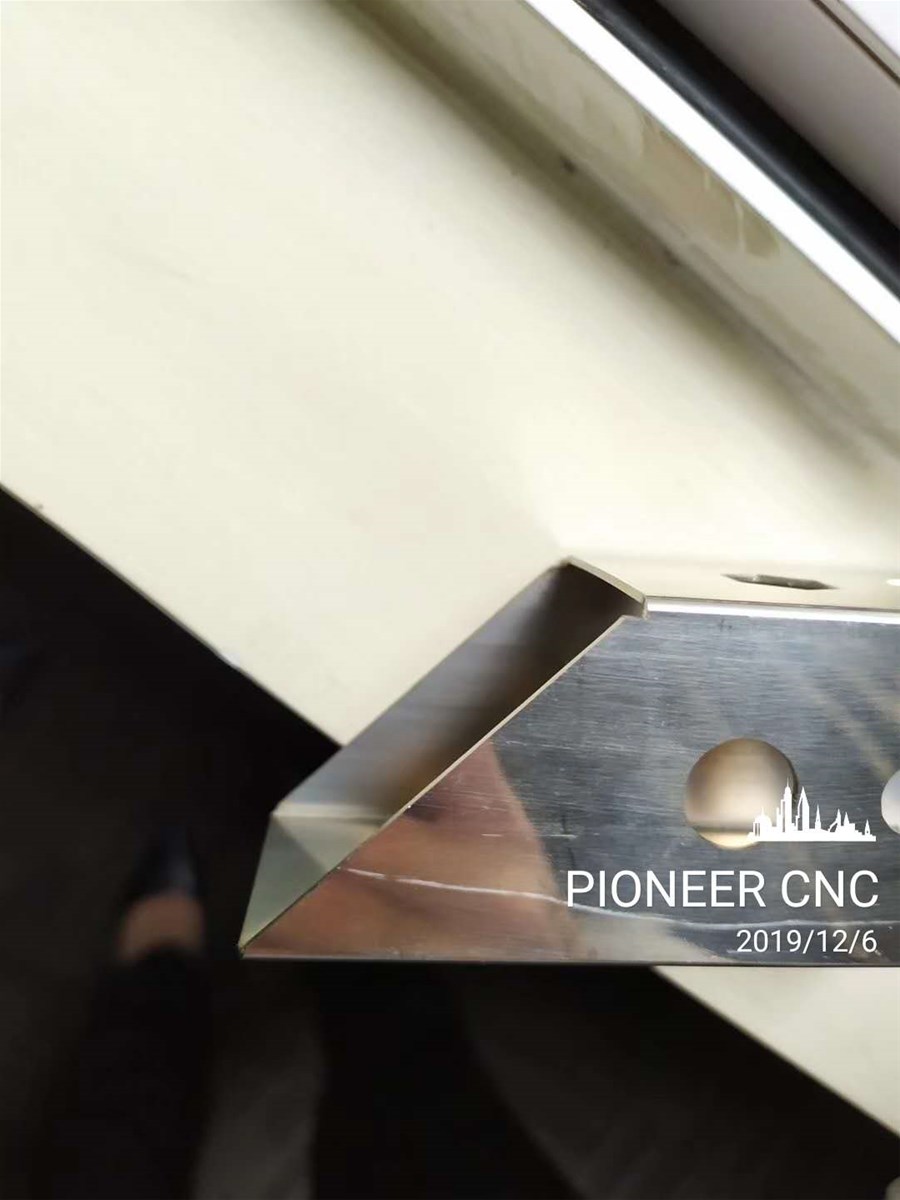

4.High precision, fast speed, narrow slit, minimum heat-affected zone, smooth cut surface, and no burr.

5. the laser cutting head does not come into contact with the surface of the material and does not scratch the workpiece.

6. the slit is the narrowest, the heat-affected zone is the smallest, the local deformation of the workpiece is very small, and there is no mechanical deformation.

7. It has good processing flexibility, can process any pattern, and can cut pipes and other profiles.

8. Non-deformable cutting can be performed on materials of any hardness such as steel plates, stainless steel, aluminum alloy plates, and hard alloys.

Laser Cutting Machine Function

1 Height Follow-up Torch Move up and Down According to Plate Height

2 Power Control Laser Power Control According to Slope

3 Reverse Function Reverse to Execute NC Program

4 Breakpoint Return Return to Breakpoint after Recovery

5 Multi Piercing Pulse, Blasting, Progress, High-Speed

6 Lead Line Set Lead Line Parameter

7 Auto-Edge Finding Find Cutting Piece Coordinate Automatically

8 Leapfrog Function Leapfrog to Improve Cutting Efficiency

9 Common Line Common Line to Improve Cutting Efficiency

10 Marking Function Mark Any Shape On Plate

Main Products Range

1.Laser cutting system;

2.Laser Welding Machine;

3.Plasma cutting system;

4.Flame cutting system;

5.Robotic cutting system;

6.High-pressure water jet cutting system;

7.Pipe profile cutting system;

8.Section steel cutting system;

9.Hydralic Press brake;

10.CNC Shearing Machine;

11.CNC Grooving Machine;

12.Welding Roller;

13.Welding Manipulator;

14.3D and 2D metal sheet and tube cutting solutions;

Delivery and Payment Terms

1:Validity: the price is valid in 30 days.

2:Price term: FOB Qingdao

3:Terms of payment: fiber laser machine: 30% deposit, 40% after acceptance and full payment before delivery;

4:Delivery time: 25 Working days after getting your deposit

5:Shipment: by sea.

Why Jinan Pioneer CNC Technology Co.,Ltd

1. Pioneer CNC technology located in Jinan, China, where is famous for the laser industry. most laser companies are here, so we have a superior geography position. and we have already established long term cooperation with stable clients and suppliers after working in the laser industry wholeheartedly in those years.

2. Team Work: after many years of development, now we have a professional team including mechanical engineer, machine designer, production engineer, sales team and sound after-sale service engineer.

We have established a strong partnership with customers from more than 100 countries. Our products have already won the trust of the market with its stable running condition, less failure rate, longer lifespan and quicker service for troubleshooting.

3. Our Sales-Network:

Jinan Pioneer CNC Technology Co., Ltd is dedicated to bringing the best laser products to world-wide customers. We are establishing our sales and distributors network all over the world. Now we already had close contact with our clients from all the world like Thailand, Indonesia, Malaysia, Singapore, India, Kuwait, U.S, Mexico, Brazil, Argentina... Welcome to work with Jinan Pioneer CNC!

Our Warranty Promise

1. All of our laser machines will be full-checked by our quality control department before the shipment. We make sure that customers will get good products from us, and all of our machines with two years quality guarantee period.

2. Our engineer will make a door-to-door instruction training service.Ps: Our technician can go to client's country offer training according to client's demand and schedule(client is supposed to afford to the tickets and visa fee, accommodation and food)

3. 24 hours online support Service response time: within 2 hours. We will offer plenty of online supports, by email, telephone, skype, whatsapp, wechat and so on.

Brief CNC Laser Cutter Introduction

this PFG-3015D double-platform laser cutting machine is a fully enclosed laser cutting machine combining with tube cutting function.Full enclosure design can not only reduce the damage of laser radiation to workers, but also effectively prevent metal debris splash from causing damage to operators.the maximum power of this metal laser cutting machine can reach 20000W. It can be used for cutting, punching and engraving various precision parts and machine panel.the metal crafts processed by the optical fiber laser cutting machine have little heat effect on the cutting seam and generally do not need secondary processing.

Application Materials

Fiber Laser Cutting Equipment is suitable for metal cutting like Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

Application Industries

Machines are widely used in manufacture Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

Main Configuration

| Laser power source | IPG/Raycus(2000w-10000w) |

| Laser head | Swiss Raytools/Germany Precitec |

| Servo motor | Japan Yaskawa |

| Reducer | Shimpo |

| Linear slider | Rexroth |

| Gear&Rack | YYC |

| Control system | CypCut |

| Machine bed | Heavy-duty plate steel welded machine bed |

| Gantry beam | Cast aluminum gantry structure |

| Water chiller | Tongfei |

| Electrical components | Schnider |

Technical Parameter

| Laser power source range | 2000w-10000w |

| Effective cutting area for plate steel | 3000mmx1500mm(can be customized) |

| Tube cutting diameter range | 20-220mm diameter |

| Tube cutting length | 6000mm(can be customized) |

| Acceleration speed | 2G |

| Positioning accuracy | ±0.03mm |

| Repeating positioning accuracy | ±0.015mm |

| Maximum moving speed | 100m/min |

the features of a laser cutting machine

1. High rigidity heavy chassis, reducing the vibration generated during the high-speed cutting process.

2.Gantry double-drive structure, with imported Germany rack & gear transmission system, which improves the production efficiency.

3. High-performance cast aluminum guide rail, after infinite analysis, which accelerates the circular arc cutting speed.

4.High precision, fast speed, narrow slit, minimum heat-affected zone, smooth cut surface, and no burr.

5. the laser cutting head does not come into contact with the surface of the material and does not scratch the workpiece.

6. the slit is the narrowest, the heat-affected zone is the smallest, the local deformation of the workpiece is very small, and there is no mechanical deformation.

7. It has good processing flexibility, can process any pattern, and can cut pipes and other profiles.

8. Non-deformable cutting can be performed on materials of any hardness such as steel plates, stainless steel, aluminum alloy plates, and hard alloys.

Laser Cutting Machine Function

1 Height Follow-up Torch Move up and Down According to Plate Height

2 Power Control Laser Power Control According to Slope

3 Reverse Function Reverse to Execute NC Program

4 Breakpoint Return Return to Breakpoint after Recovery

5 Multi Piercing Pulse, Blasting, Progress, High-Speed

6 Lead Line Set Lead Line Parameter

7 Auto-Edge Finding Find Cutting Piece Coordinate Automatically

8 Leapfrog Function Leapfrog to Improve Cutting Efficiency

9 Common Line Common Line to Improve Cutting Efficiency

10 Marking Function Mark Any Shape On Plate

Main Products Range

1.Laser cutting system;

2.Laser Welding Machine;

3.Plasma cutting system;

4.Flame cutting system;

5.Robotic cutting system;

6.High-pressure water jet cutting system;

7.Pipe profile cutting system;

8.Section steel cutting system;

9.Hydralic Press brake;

10.CNC Shearing Machine;

11.CNC Grooving Machine;

12.Welding Roller;

13.Welding Manipulator;

14.3D and 2D metal sheet and tube cutting solutions;

Delivery and Payment Terms

1:Validity: the price is valid in 30 days.

2:Price term: FOB Qingdao

3:Terms of payment: fiber laser machine: 30% deposit, 40% after acceptance and full payment before delivery;

4:Delivery time: 25 Working days after getting your deposit

5:Shipment: by sea.

Why Jinan Pioneer CNC Technology Co.,Ltd

1. Pioneer CNC technology located in Jinan, China, where is famous for the laser industry. most laser companies are here, so we have a superior geography position. and we have already established long term cooperation with stable clients and suppliers after working in the laser industry wholeheartedly in those years.

2. Team Work: after many years of development, now we have a professional team including mechanical engineer, machine designer, production engineer, sales team and sound after-sale service engineer.

We have established a strong partnership with customers from more than 100 countries. Our products have already won the trust of the market with its stable running condition, less failure rate, longer lifespan and quicker service for troubleshooting.

3. Our Sales-Network:

Jinan Pioneer CNC Technology Co., Ltd is dedicated to bringing the best laser products to world-wide customers. We are establishing our sales and distributors network all over the world. Now we already had close contact with our clients from all the world like Thailand, Indonesia, Malaysia, Singapore, India, Kuwait, U.S, Mexico, Brazil, Argentina... Welcome to work with Jinan Pioneer CNC!

Our Warranty Promise

1. All of our laser machines will be full-checked by our quality control department before the shipment. We make sure that customers will get good products from us, and all of our machines with two years quality guarantee period.

2. Our engineer will make a door-to-door instruction training service.Ps: Our technician can go to client's country offer training according to client's demand and schedule(client is supposed to afford to the tickets and visa fee, accommodation and food)

3. 24 hours online support Service response time: within 2 hours. We will offer plenty of online supports, by email, telephone, skype, whatsapp, wechat and so on.