| Application: | Laser Cutting |

|---|---|

| Certification: | CE,ISO,SGS |

| Brand Name: | Pioneer Laser |

| Graphic Format Supported: | DST,DWG,DXF |

| Applicable Material: | Metal |

| Laser Type: | Fiber Laser |

| After-sales Service Provided: | Engineers available to service machinery overseas |

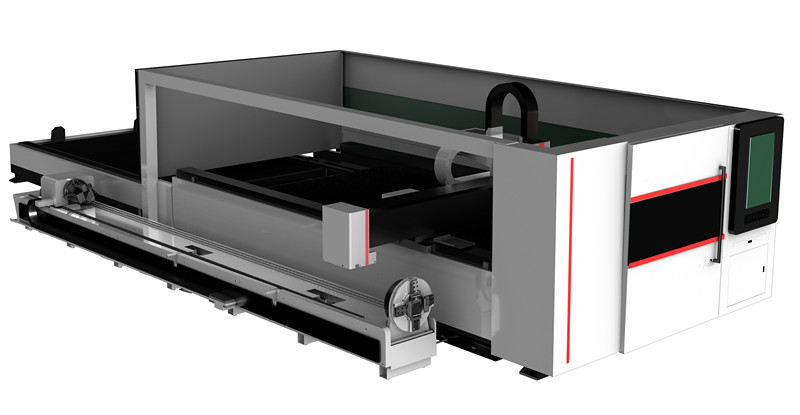

| Model Number: | PG-6020 |

| Place of Origin: | China (Mainland) |

| Control Software: | CypCut |

| Cooling Mode: | Water Cooling |

| CNC or Not: | Yes |

| Cutting Speed: | 100m/min |

| Cutting Area: | 1500mmx3000mm |

| Cutting Thickness: | 25mm |

| Condition: | New |

| Control system: | CypCut |

| Laser power source: | IPG |

| Laser head: | Precitec |

| Servo motor: | Yaskawa |

| Rack&pinion: | YYC |

| Linear slider: | Hiwin |

| Water cooling: | Tongfei |

| Positioning accuracy: | &plus0.03mm |

| Accleration: | 2G |

| Trademark: | Pioneer Laser |

Quick Details

Specifications

High Speed Fiber Laser Tube Cutting Machine CNC Tube Laser Cutter for Sale

1.PG-6020L tube laser fiber cutting machine is professional tube cutting fiber laser machine, suitable for all kinds of stainless tube, round tube, square tube and oval tube.

2.It can satisfy various tube cutting process such as tube cutting-off,tube hole cutting,or any shapes cutting on tube surface.

3.the machine adopt Raycus laser source,Swiss Raytools auto focus laser head,Japan Yaskawa servo motor to give you perfect tube laser cutting performance meanwhile ensure long time stable running,less failure rate,maintenance costetc

4.It can be also equipped with automatic material loading system to higher efficience,it is optional according to your demands.

the advantages of Pioneer laser tube cutting machine

Main Function of Laser Tube Cutter

1.both front and rear chucks adopt pneumatic chucks, one-key automatic centering and double-drive rotation to ensure synchronous front and rear rotation, short stroke, high efficiency and no deformation of thin plates;

2.Ultra-short tailings processing reduces the cost of raw materials, lower costs and drives more possibilities.

3.Imported servo motor with large torque to ensure the high speed and acceleration of the whole machine.

the function of CNC laser tube cutter

1. A plurality of cylindrical intersecting line holes with different directions and diameters can be cut on the main pipe to meet the conditions of eccentric and non-eccentric vertical intersection of the branch pipe axis and the main pipe axis;

2. the end of the cylindrical intersecting line can be cut at the end of the branch pipe to meet the conditions of eccentric vertical intersection and inclined intersection of the branch pipe axis and the main pipe axis;

3. It is possible to cut the oblique end face at the end of the circular tube.

4. the cutting of the intersection line end of the branch pipe intersecting with the annular main pipe can be realized;

5.It can cut bevel face, square hole and waist hole with variable angle.

Main configuration of CNC laser cutting machine

Cutting capacity of different power laser source

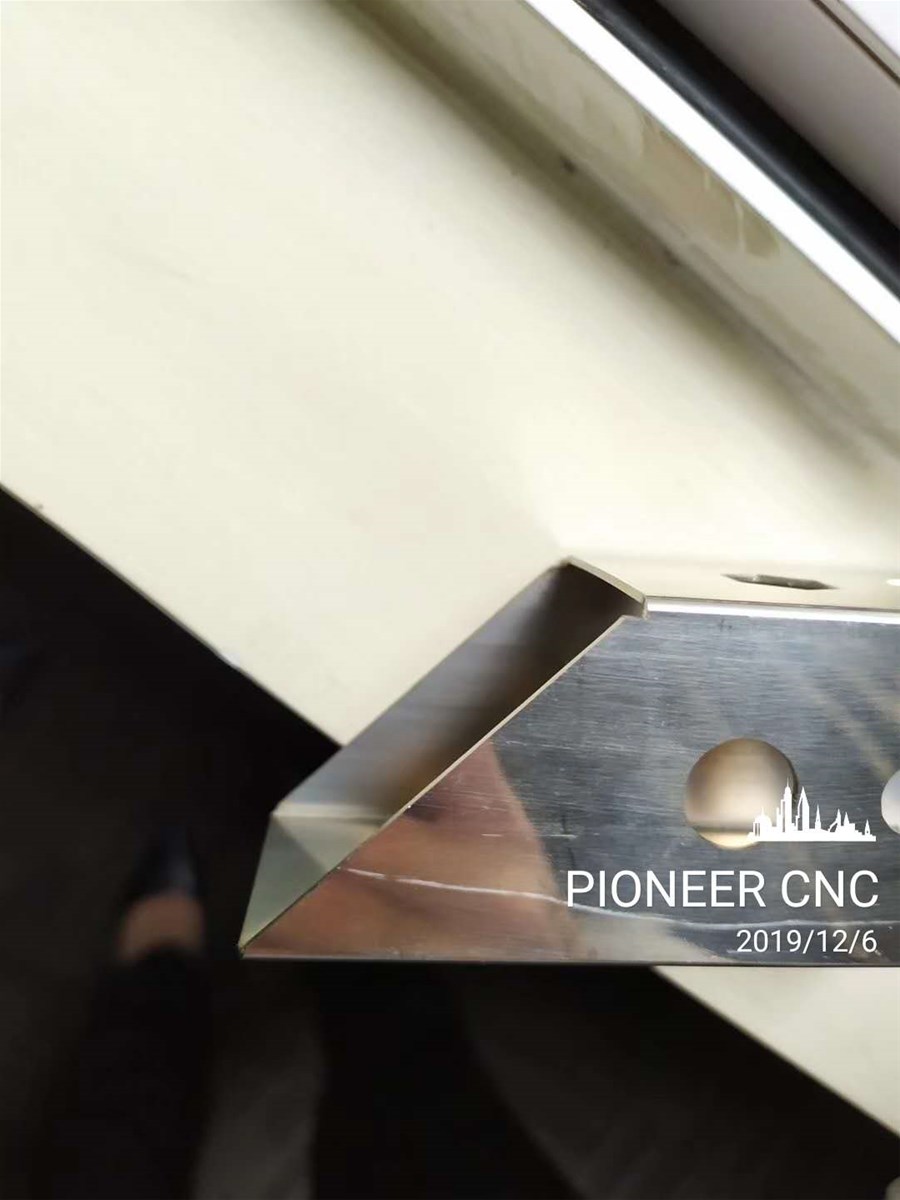

CNC Fiber Laser Cutter Cut Stainless Steel

while we cut stainless steel with a CNC fiber laser cutting machine,we prefer to use N2 rather than use O2.

N2 can protect stainless steel from oxidation while laser cutting,less glitch,so there is no need secondary polishing for welding.According to the material properties of stainless steel,N2 can acclerate liquid flow,so the cutting efficiency quicker.but if we use O2 to cust stainless steel,there will be no smooth and black end cutting face.

CNC Fiber Laser Cutter Cut Carbon Steel

O2 is a good choice to cut carbon steel with CNC fiber laser cutting machine.Oxygen reaction heat will improve cutting efficiency a lot,meanwhile,oxide file can improve spectral absorption factor of reflective materials.

but tiny oxidation on the end might be a problem while use o2 to cut carbon steel.

If you need high precision cutting,you can use N2 for high pressure cutting

CNC Fiber Laser Cutter Cut Aluminum

Aluminum is high reflection material,which has high reflectivity and thermal condictivity.

so anti-reflection device is necessary to protect inner optical components.Generally speaking,for same power CNC laser cutter,its capacity for carbon steel and stainless steel will be thicker than for aluminum.

Also,N2 is suitable to cut aluminum with laser cutting machinery.

CNC Fiber Laser Cutter Cut Copper

Same as aluminum,copper is kind of high reflection material.

Anti-reflectivity device is necessary also when choose suitable laser cutting machine.

and N2 is a good gas choice while cooper laser cutting.

Advantages of CNC Fiber Laser Cutting Machine

1.Laser cutting machine can replace traditional die punching,save mould manufacturing cost by 80%;

2.Laser cutting can satisfy small batch,complicated trajectory plate steel cutting process;

3.CNC laser cutter is computer controled,less operating error;

4.CNC laser cutting machine can realize whole plate steel nesting function,easy to operate,higher working efficiency a lot;

5.Laser cutting has better cutting precision and cutting surface smoothness.

about Jinan Pioneer CNC Technology Co.,Ltd

Jinan Pioneer CNC Technology Co.,Ltd is a high technology company which specialized in R&D,sale of fiber laser cutting machine,laser tube cutting machine,3D robot laser cutting line,robot laser welding automation line,handheld laser welding machine,laser cleaner,laser marking machines.

Our products are widely used in advertising signs,soft metal laser cutting,metal craft gifts,metal processing industries,kitchen utensils,metal hardware,fitness equipmentetc.

to satisfy diversified market demands,we will keep innovative,keep bettering our quality and service to provide the best laser cutting & laser welding solution for our customers.

Why choose Jinan Pioneer CNC Technology Co.,Ltd

1. Pioneer CNC technology located in Jinan, China, where is famous for laser industry. most laser companies are here, so we have superior geography position. and we have already established long term cooperation with stable clients and suppliers after working in laser industry wholeheartedly in those years.

2. Team Work: after many years development,now we have a professional team including mechanical engineer, machine designer,production engineer,sale team and sound after sale service engineer.

We have established strong partnership with customers from more than 100 countries.Our products have already win the trust of market with its stable running condition,less failure rate,longer lifespan and quicker service for trouble shooting.

3. Our Sales-Network:

Jinan Pioneer CNC Technology Co.,Ltd is dedicated to bringing best laser products to the world-wide customers. We are establishing our sales and distributors network all over the world. Now we already had close contact with our clients from all the world like Thailand, Indonesia, Malaysia, Singapore, India, Kuwait, U.S, Mexico, Brazil, Argentina.... Welcome to work with Jinan Pioneer CNC!

Our Warranty Promise

1. All of our machine will be full-checked by our quality control department before the shipment. We make sure that customers will be get good products from us, and all of our machine with two years quality guarantee period.

2. Our engineer will make a door-to-door instruction training service.Ps:Our technician can go to client's country offer training according to client's demand and schedule(client is supposed to afford to the tickets and visa fee,accommodation and food)

3. 24 hours online support,Service response time: within 2 hours .We will offer plenty of online supports, by email, telephone, skype, whatsapp, wechat and so on.

Related Machines

1.PG-6020L tube laser fiber cutting machine is professional tube cutting fiber laser machine, suitable for all kinds of stainless tube, round tube, square tube and oval tube.

2.It can satisfy various tube cutting process such as tube cutting-off,tube hole cutting,or any shapes cutting on tube surface.

3.the machine adopt Raycus laser source,Swiss Raytools auto focus laser head,Japan Yaskawa servo motor to give you perfect tube laser cutting performance meanwhile ensure long time stable running,less failure rate,maintenance costetc

4.It can be also equipped with automatic material loading system to higher efficience,it is optional according to your demands.

the advantages of Pioneer laser tube cutting machine

Main Function of Laser Tube Cutter

1.both front and rear chucks adopt pneumatic chucks, one-key automatic centering and double-drive rotation to ensure synchronous front and rear rotation, short stroke, high efficiency and no deformation of thin plates;

2.Ultra-short tailings processing reduces the cost of raw materials, lower costs and drives more possibilities.

3.Imported servo motor with large torque to ensure the high speed and acceleration of the whole machine.

the function of CNC laser tube cutter

1. A plurality of cylindrical intersecting line holes with different directions and diameters can be cut on the main pipe to meet the conditions of eccentric and non-eccentric vertical intersection of the branch pipe axis and the main pipe axis;

2. the end of the cylindrical intersecting line can be cut at the end of the branch pipe to meet the conditions of eccentric vertical intersection and inclined intersection of the branch pipe axis and the main pipe axis;

3. It is possible to cut the oblique end face at the end of the circular tube.

4. the cutting of the intersection line end of the branch pipe intersecting with the annular main pipe can be realized;

5.It can cut bevel face, square hole and waist hole with variable angle.

Main configuration of CNC laser cutting machine

| Laser power source | IPG/Raycus(1000w,2000w,3000w optional) |

| Laser head | Swiss Raytools or Germany Precitec |

| Servo motor | Japan Yaskawa servo motor |

| Electrical components | Schneider |

| Liner slider | TBI |

| Rack&pinion | YYC |

| Machine bed | Heavy plate steel welded |

Cutting capacity of different power laser source

| Laser power source | 1000w | 2000w | 3000w | 4000w | 6000w |

| cutting capacity | |||||

| Carbon steel(mm) | 10 | 15 | 20 | 20 | 25 |

| Stainless steel(mm) | 4 | 8 | 12 | 15 | 20 |

| Aluminum(mm) | 2 | 6 | 12 | 12 | 15 |

| Brass(mm) | 2 | 4 | 6 | 8 | 10 |

| Copper(mm) | 2 | 4 | 6 | 8 | 10 |

CNC Fiber Laser Cutter Cut Stainless Steel

while we cut stainless steel with a CNC fiber laser cutting machine,we prefer to use N2 rather than use O2.

N2 can protect stainless steel from oxidation while laser cutting,less glitch,so there is no need secondary polishing for welding.According to the material properties of stainless steel,N2 can acclerate liquid flow,so the cutting efficiency quicker.but if we use O2 to cust stainless steel,there will be no smooth and black end cutting face.

CNC Fiber Laser Cutter Cut Carbon Steel

O2 is a good choice to cut carbon steel with CNC fiber laser cutting machine.Oxygen reaction heat will improve cutting efficiency a lot,meanwhile,oxide file can improve spectral absorption factor of reflective materials.

but tiny oxidation on the end might be a problem while use o2 to cut carbon steel.

If you need high precision cutting,you can use N2 for high pressure cutting

CNC Fiber Laser Cutter Cut Aluminum

Aluminum is high reflection material,which has high reflectivity and thermal condictivity.

so anti-reflection device is necessary to protect inner optical components.Generally speaking,for same power CNC laser cutter,its capacity for carbon steel and stainless steel will be thicker than for aluminum.

Also,N2 is suitable to cut aluminum with laser cutting machinery.

CNC Fiber Laser Cutter Cut Copper

Same as aluminum,copper is kind of high reflection material.

Anti-reflectivity device is necessary also when choose suitable laser cutting machine.

and N2 is a good gas choice while cooper laser cutting.

Advantages of CNC Fiber Laser Cutting Machine

1.Laser cutting machine can replace traditional die punching,save mould manufacturing cost by 80%;

2.Laser cutting can satisfy small batch,complicated trajectory plate steel cutting process;

3.CNC laser cutter is computer controled,less operating error;

4.CNC laser cutting machine can realize whole plate steel nesting function,easy to operate,higher working efficiency a lot;

5.Laser cutting has better cutting precision and cutting surface smoothness.

about Jinan Pioneer CNC Technology Co.,Ltd

Jinan Pioneer CNC Technology Co.,Ltd is a high technology company which specialized in R&D,sale of fiber laser cutting machine,laser tube cutting machine,3D robot laser cutting line,robot laser welding automation line,handheld laser welding machine,laser cleaner,laser marking machines.

Our products are widely used in advertising signs,soft metal laser cutting,metal craft gifts,metal processing industries,kitchen utensils,metal hardware,fitness equipmentetc.

to satisfy diversified market demands,we will keep innovative,keep bettering our quality and service to provide the best laser cutting & laser welding solution for our customers.

Why choose Jinan Pioneer CNC Technology Co.,Ltd

1. Pioneer CNC technology located in Jinan, China, where is famous for laser industry. most laser companies are here, so we have superior geography position. and we have already established long term cooperation with stable clients and suppliers after working in laser industry wholeheartedly in those years.

2. Team Work: after many years development,now we have a professional team including mechanical engineer, machine designer,production engineer,sale team and sound after sale service engineer.

We have established strong partnership with customers from more than 100 countries.Our products have already win the trust of market with its stable running condition,less failure rate,longer lifespan and quicker service for trouble shooting.

3. Our Sales-Network:

Jinan Pioneer CNC Technology Co.,Ltd is dedicated to bringing best laser products to the world-wide customers. We are establishing our sales and distributors network all over the world. Now we already had close contact with our clients from all the world like Thailand, Indonesia, Malaysia, Singapore, India, Kuwait, U.S, Mexico, Brazil, Argentina.... Welcome to work with Jinan Pioneer CNC!

Our Warranty Promise

1. All of our machine will be full-checked by our quality control department before the shipment. We make sure that customers will be get good products from us, and all of our machine with two years quality guarantee period.

2. Our engineer will make a door-to-door instruction training service.Ps:Our technician can go to client's country offer training according to client's demand and schedule(client is supposed to afford to the tickets and visa fee,accommodation and food)

3. 24 hours online support,Service response time: within 2 hours .We will offer plenty of online supports, by email, telephone, skype, whatsapp, wechat and so on.

Related Machines