| Material: | Iron |

|---|---|

| Brand Name: | JUFENG |

| Application: | Municipal Building |

| size: | OEM manhole cover |

| Type: | Round and Square |

| Model Number: | B125 C250 D400 E600 |

| Place of Origin: | China (Mainland) |

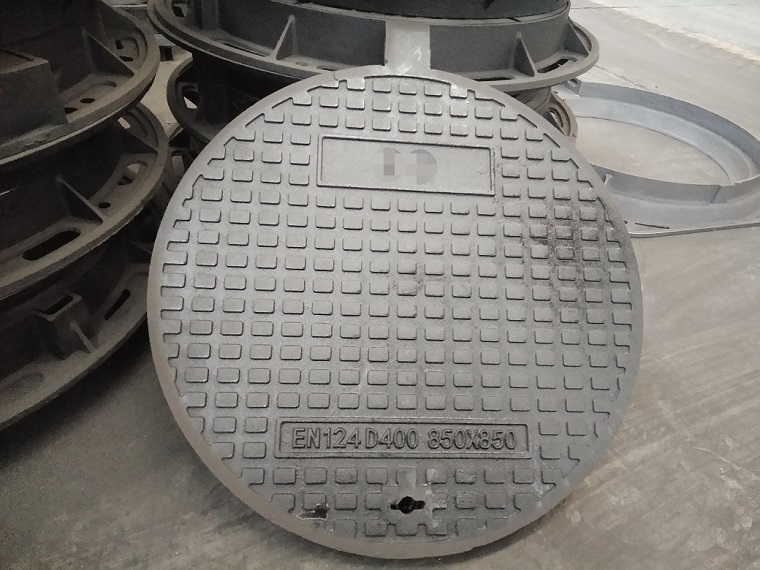

| Product Name: | Manhole Cover |

| Materials 1: | Ductile Iron |

| Materials 2: | Cast Iron |

| Manufacturing Process: | Sand Casting |

| Painting type: | Good Black Bitumen |

| Standard: | En124 |

| Class: | B125 C250 D400 E600 |

| Export Port: | Tianjin |

| HS code: | 7325109000 |

Quick Details

Specifications

Our advantage:

Molding Flask Measure:960960180-220mm

Production efficiency:150 M/H

2.Product Development: Jufeng company develops casting products in depth, and adopts CAD and CAE 3D software for 3D design and simulation in product development and trial production. Especially, it has a high professional technical level in the application of UG and Solid Works digital design software.

3.Mould Making and CNC Machining Center: In order to develop new products and make mould, Jufeng company has set up a CNC Machining Center. from design,mould making to processing of casting products are completed through computer program and CNC machine tools, we achieves to make mould and process the Casting in the later stage directly by CNC lathes, CNC milling machines and other equipment for precision machining in our own company.

1.Moulding technology: Adopting German technology produced large and efficient Double Station Horizontal Static Pressure PLC control Full Automatic Molding Line, which is the most advanced wet sand molding line in China.

Production equipment: Double Station Horizontal Static Pressure Automatic Molding LineMolding Flask Measure:960960180-220mm

Production efficiency:150 M/H

2.Product Development: Jufeng company develops casting products in depth, and adopts CAD and CAE 3D software for 3D design and simulation in product development and trial production. Especially, it has a high professional technical level in the application of UG and Solid Works digital design software.

3.Mould Making and CNC Machining Center: In order to develop new products and make mould, Jufeng company has set up a CNC Machining Center. from design,mould making to processing of casting products are completed through computer program and CNC machine tools, we achieves to make mould and process the Casting in the later stage directly by CNC lathes, CNC milling machines and other equipment for precision machining in our own company.