| Type: | Coaxial |

|---|---|

| Brand Name: | futong |

| Application: | Communication cable |

| Color: | black |

| Model Number: | GYTA33 |

| Place of Origin: | China (Mainland) |

Quick Details

Specifications

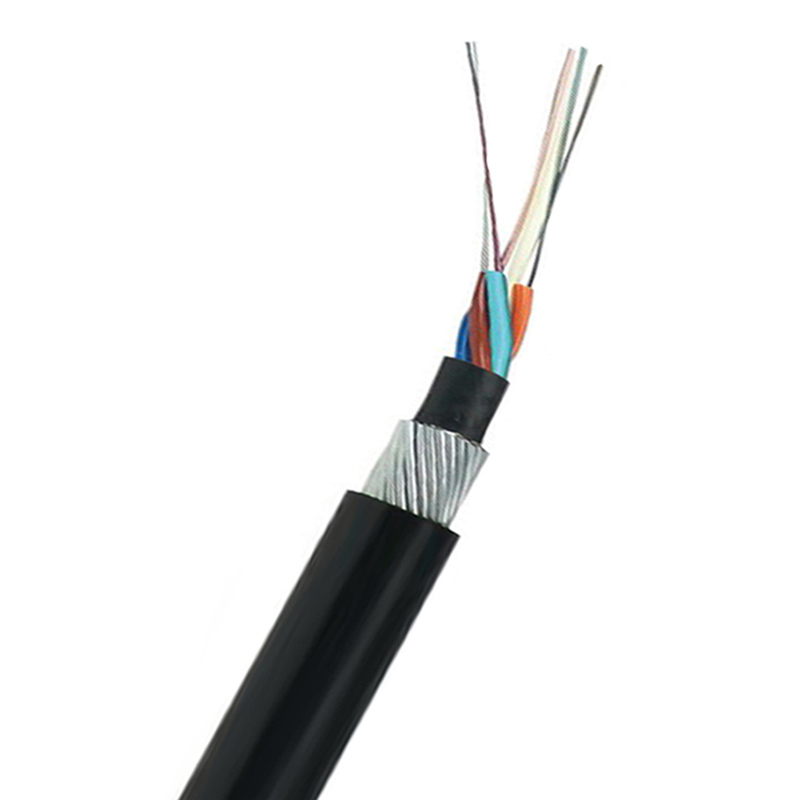

the structure of GYTA33 fiber optic cable is based on the structure of GYTA fiber optic cable, strengthening the waterproof function and anti-extrusion function. It is to coat the fiber into the loose sleeve made of PE material, and fill the sleeve with waterproof compound material. At the center of the cable core is a metal reinforced core. For some fiber optic cables, a layer of polyethylene (PE) is added to the metal reinforced core. The loose sleeve is twisted around the central stiffener to form a compact circular core, and the gaps in the core are filled with water-blocking filler. Coated with aluminum strip longitudinal package after extruding a layer of PE inner sheath, and then longitudinally coated single or double layer of thin round steel wire armor, finally extruded polyethylene outer layer into cable.

Product features:

Accurate residual length control to ensure that the cable has a good tensile performance and temperature characteristics;

/ with good mechanical properties and temperature characteristics;

Thin round steel wire armor to make the cable has a stronger tensile performance;

Tight and compact structure, excellent bending performance, good compression resistance and flexibility, easy to operate.

/ after cabled, the additional attenuation of the fiber is almost zero, and the dispersion value is unchanged;

Service life over 30 years;

Pecifications

Product features:

Accurate residual length control to ensure that the cable has a good tensile performance and temperature characteristics;

/ with good mechanical properties and temperature characteristics;

Thin round steel wire armor to make the cable has a stronger tensile performance;

Tight and compact structure, excellent bending performance, good compression resistance and flexibility, easy to operate.

/ after cabled, the additional attenuation of the fiber is almost zero, and the dispersion value is unchanged;

Service life over 30 years;

GYTA33 submarine ungroun fiber optic cable

Application

Laying method: Duct/undground/undsea river

Suitable for Installation when a communication line hes to span a river, a valley etc. Tough occasion.

Characteristics: |

LAP Aluminum belt is applied around the cable core, which is filled with the filling compound

to protect it from water-ingress |

Accurate fiber excess length ensures good mechaical and temperature performance |

Specially desinged compact structure is good at preventing loose tubes from shrinking |

High strength loose tube that is hydroysis resistant and special tube filling compound ensure

a citical protection of fiber |

Small diameter, light weight and it is easy to be installed |

Technical parameters | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

*the structur, es in the list are all typical, the cable structure also can be design according customer'srequirement.

Optic Characteristics:

Remarks: Also making following customer's request.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||