| Type: | Ball |

|---|---|

| Structure: | Angular Contact |

| Outside Diameter: | 80 mm |

| Bore Size: | 145 mm |

| Brand Name: | MONTON |

| Structure: | balls |

| Type: | thrust |

| Place of Origin: | China (Mainland) |

| Number of Row: | Double Row |

| Seals Type: | no seals |

| Precision Rating: | P4 |

| Model Number: | 128816KBX |

Quick Details

Specifications

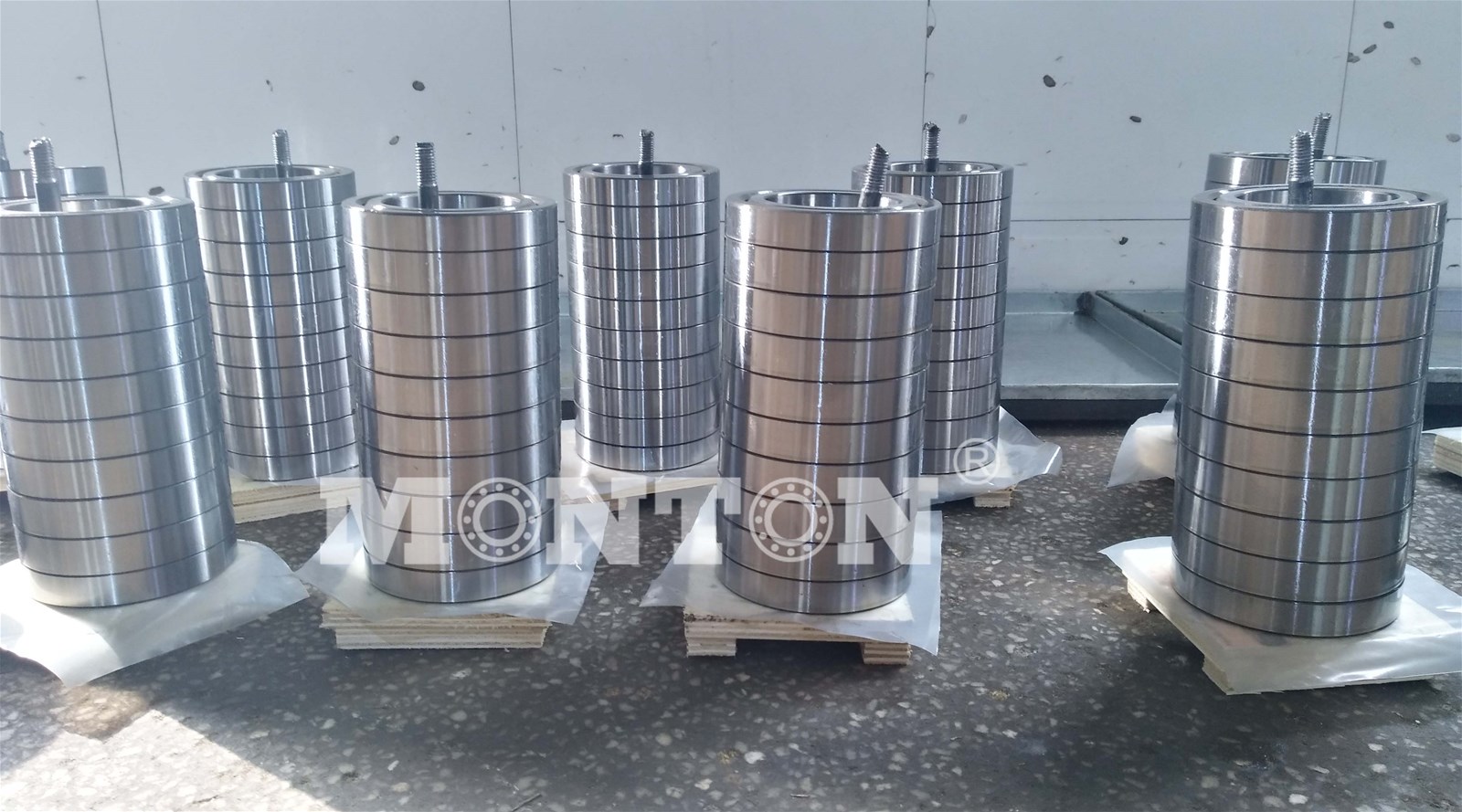

128816KBX 145*80*347mm Mud motor Radial Bearings

| Drilling Tools | Bearing | d | D | H |

| LZ165 | 128816KBX | 80 | 145 | 347 |

Lubrication Mud Motor Bearings, Mudstack Thrust Bearings for Downhole Drilling Tools

Monton solutions for downhole drilling tools

whether you're drilling for oil or gas, drill strings must endure extreme operating conditions. Monton solutions for downhole drilling tools are designed to increase performance and reliability.

Cylindrical thrust bearings

to provide superior axial thrust load support for sealed motors, Monton's cylindrical thrust bearings are manufactured to the highest quality standards. the contact surfaces between the rollers and the raceways, and the internal geometry are all controlled to extremely tight tolerances to improve performance compared to low-quality cylindrical thrust bearings available in the marketplace.

Tungsten carbide radial bearings

Specially designed to provide excellent radial load support for both sealed and mud motors, Monton tungsten carbide radial bearings are made using a unique microwave sintering process (resulting in 1 600 Vickers hardness) as compared to typical conventional sintering (with 1 000 Vickers hardness). this results in a high hardness of 92 HRa for excellent wear resistance and longer life.

Downhole sealing solutions

Monton has innovative seal designs and quality materials for downhole rotating seals exposed to high pressure. the Monton Teflathene seal incorporates a low-friction PTFE seal ring bonded to a rubber body. The all-rubber DM2 seal separates drifting mud from lubricants in oil-lubricated mud motor bearings. Bottom hole assembly (BHA) tools such as shocks and jars require seals to protect the tool hydraulics from the abrasive drill muds and cuttings in the hole. Measure-while-drilling (MWD) tools sometimes require high-temperature sealing solutions.Monton has developed a full line of field-proven seals to work in this demanding environment, including a seal capable of withstanding up to 315 °C (600 °F).

Mud stack thrust bearings

Mud bearings close to the drill string end have a major impact on productivity and reliability. In addition to severe axial and shock loads, these bearings are " lubricated" with highly abrasive mud, which for a bearing is the definition of an extreme operating condition. Monton's mudstack bearings are optimized for our customers' applications through rigorous finite element analysis and physical lab tests by testing the bearings with drilling mud circulating through them.

Monton mudstack bearings provide:

Improved wear resistance

Increased load-carrying capacity

Optimized load distribution

Increased robustness

Improved reliability

Customized design

Product Description

the bearings in a mud motor at the end of a drill string would place a huge influence on productivity and reliability in terms of oil drilling or gas drilling.the working condition of these mud motor bearings are extremely harsh: the bearings bear heavy axial and

Shock loads, and they are also exposedwith highly abrasive mud.

Special steel for all bearing components

Full complement bearing

Precision matched rings

Unique bearing design to support heavy

Axial drilling loads

Application:

Oil drilling motor

Downhole motor

Electric submersible pump

Bearing life:

300hours

Main Customers:

Oil company like:SLB,Halliburton or GE

Main application:

Downhole motor or drilling motor