| Type: | Filling Machine |

|---|---|

| Brand Name: | Well Machinery |

| Packaging Material: | Wood |

| Packaging Type: | Bottles |

| Application: | Beverage |

| Condition: | New |

| After-sales Service Provided: | Engineers available to service machinery overseas |

| Certification: | CE |

| Weight: | 4.5T |

| Dimension(L*W*H): | 600*700*800 |

| Model Number: | DCGF |

| Place of Origin: | China (Mainland) |

| Power: | 3KW |

| Voltage: | 380V |

| Driven Type: | Electric |

| Automatic Grade: | Automatic |

| Product Name: | Soft drink filling capping machine made in China with good price |

| Function: | Bottle Washing Filling Capping |

| Filling material: | Beverage |

| Usage: | Beverage Packaging |

| Bottle type: | PET Plastic Bottle |

| Warranty: | Maintenance |

| Processing Types: | Automatic Bottle Filling Sealing Machine |

| Control: | PLC+ Touch Screen |

Quick Details

Specifications

Products Description

Pet Bottle Carbonated Drink Filling Line

Washing heads

<1>All 304/316stainless steel rinse heads, water spray style inject design, more save water consumption and more clean

<2>304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

<3> 304/316 stainless steel washing pump

Company Profile

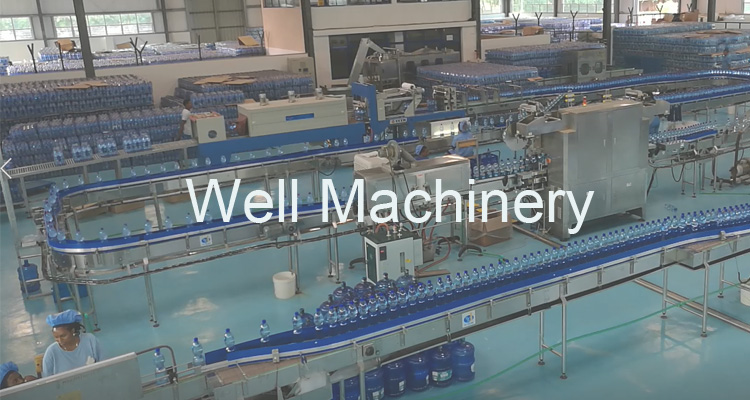

Well Machinery

Well Machinery

Pet Bottle Carbonated Drink Filling Line

the machine is mainly used for filling carbonated drink. It combines rinsing and filling and capping as one automatic body suitable for PET or other plastic bottles. The iso-pressure (iso-barometric) filling technology is adopted enabling it to fill more efficiently and more stably with more output than the machine of the same level from others.

Main Features.

1. Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this

Enable the change the bottle-shaped become easier.

2. Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only

Change related the curved plate, wheel and nylon parts is enough..

3. the specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of

Bottle mouth to avoid secondary pollution.

4. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's

Mitsubishi, France Schneider, OMRON.

Details Images

Main Features.

1. Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this

Enable the change the bottle-shaped become easier.

2. Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only

Change related the curved plate, wheel and nylon parts is enough..

3. the specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of

Bottle mouth to avoid secondary pollution.

4. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's

Mitsubishi, France Schneider, OMRON.

Details Images

<1>All 304/316stainless steel rinse heads, water spray style inject design, more save water consumption and more clean

<2>304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

<3> 304/316 stainless steel washing pump

Filling heads

<1> 304/316 Stainless steel high precision filling nozzle

<2> Filling volume adjustable in fine rank, same liquid level after filling

<3> All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

<4> 304/316 stainless steel filling pump

Capping heads

<1> Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping <2> All 304/316 stainless steel construction <3> No bottle no capping <4> Automatic stop when lack of bottle

CertificationsCapping heads

<1> Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping <2> All 304/316 stainless steel construction <3> No bottle no capping <4> Automatic stop when lack of bottle

Company Profile

<1> Standardized workshop ofTotal 12,000 square meters.<2>with aMore than 30 professionals teamto design and develop, is a key professional enterprise, which integrates development,research, design, manufacture, technology service and marketing.

<3>Well Machinery followsISO9001:2001; CE Certificate, SGS, COC, TUVInternational quality management system.

<4>the equipment will beTested and run for 24 hours beforeLeaving the factory, to ensure the smooth working of water pipeline,and pneumatic, electrical and mechnical stability.

<5>Sufficient stock of spare partsEnsures the timely delivery and supply of spare parts.

<6>Professional installation teamWho can speak fluent English can help customers make benefits in a shortest time.

Product packaging

Packing & Delivery.

FAQ

Packing & Delivery.

FAQ

Q1:Do you have reference project?

A1: We have reference project in most countries,If we get the permission of the customer who has brought the machines from us,you can go to vist their factory..and you are always welcome to come to visit our company,and see the machine running in our factory,we can pick you up from the station near our city. Our sales people you can get video of our reference running machine

Q2:Do you have agent and after-service stations?

A2: so far we have agent in Yemen,Nigeria,Dubai,India,Kenya,Dubai welcome to join us!

Q3:Do you provide customized service

A3: We can design the machines according your requirements(materil,power,filling type,the kinds of the bottles,and so on),at the same time we will give you our professional suggestion,as you know,we have been in this industry for many years.

Q4:What's your guarantee or the warranty of the quality if we buy your machines?A4: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q5:how long time for installation?A5: According your machines order,we will send one or two engineers to your plant,it will take about 10 days to 25 days.

Product packaging

Package Type: as usual, we adopt wooden case as package type. It's suitable for long-distance transport. According to customers'

Special demand, we could adopt sheet iron case and so on.

Special demand, we could adopt sheet iron case and so on.

Q1:Do you have reference project?

A1: We have reference project in most countries,If we get the permission of the customer who has brought the machines from us,you can go to vist their factory..and you are always welcome to come to visit our company,and see the machine running in our factory,we can pick you up from the station near our city. Our sales people you can get video of our reference running machine

Q2:Do you have agent and after-service stations?

A2: so far we have agent in Yemen,Nigeria,Dubai,India,Kenya,Dubai welcome to join us!

Q3:Do you provide customized service

A3: We can design the machines according your requirements(materil,power,filling type,the kinds of the bottles,and so on),at the same time we will give you our professional suggestion,as you know,we have been in this industry for many years.

Q4:What's your guarantee or the warranty of the quality if we buy your machines?A4: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q5:how long time for installation?A5: According your machines order,we will send one or two engineers to your plant,it will take about 10 days to 25 days.