| Type: | Filling Machine |

|---|---|

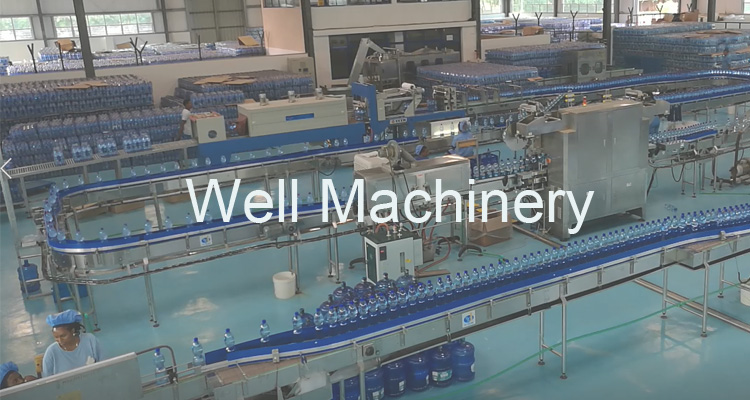

| Brand Name: | Well Machinery |

| Packaging Material: | Wood |

| Packaging Type: | Bottles |

| Application: | Beverage |

| Condition: | New |

| After-sales Service Provided: | Engineers available to service machinery overseas |

| Certification: | CE |

| Weight: | 4.5T |

| Dimension(L*W*H): | 600*700*800 |

| Model Number: | RCGF |

| Place of Origin: | China (Mainland) |

| Power: | 3KW |

| Voltage: | 380V |

| Driven Type: | Electric |

| Automatic Grade: | Automatic |

| Product Name: | Complete turnkey drink fruit juice hot filling machine production line |

| Function: | Bottle Washing Filling Capping |

| Filling material: | Juice |

| Usage: | Beverage Packaging |

| Bottle type: | PET Plastic Bottle |

| Warranty: | Maintenance |

| Processing Types: | Automatic Bottle Filling Sealing Machine |

| Control: | PLC+ Touch Screen |

Quick Details

Specifications

Products Description

PET bottle juice filling machine

PET bottle juice filling machine

this Machine Series is designed for non-carbonated beverages filling, like Juice, Tea Drink, Dairy Drink etc.Air conveyor is connected with 3-in-1 monoblock directly. Bottle transport adopts neck-fixing way. Its advantages:

When user needs to change bottle size but bottle diameter does not change or just changes a little, our machine no need to be adjusted to switch for different bottle size. When bottle diameter changes bigger, it only takes very short time within 10-30minutes to replace change-over parts. It is very convenient for user and saves the cost and time of switching bottle formats.

Details Images

Washing part

Filling part

When user needs to change bottle size but bottle diameter does not change or just changes a little, our machine no need to be adjusted to switch for different bottle size. When bottle diameter changes bigger, it only takes very short time within 10-30minutes to replace change-over parts. It is very convenient for user and saves the cost and time of switching bottle formats.

Details Images

Washing part

<1>All 304/316stainless steel rinse heads, water spray style inject design, more save water consumption and more clean

<2>304/316Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

<3> 304/316 stainless steel washing pump.

<2>304/316Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

<3> 304/316 stainless steel washing pump.

Filling part

<1>304/316 Stainless steel high precision filling nozzle

<2>Filling volume adjustable in fine rank, same liquid level after filling

<3>All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean.

<4>304/316 stainless steel filling pump.

Capping part

Company Profile

ZHANGJIAGANG WELL MACHINE CO.,LTD.

<2>Filling volume adjustable in fine rank, same liquid level after filling

<3>All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean.

<4>304/316 stainless steel filling pump.

Capping part

<1>Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash duringcapping

<2>All 304/316 stainless steel construction.

<3>No bottle no capping.

<4>Automatic stop when lack of bottle.

Certifications

<2>All 304/316 stainless steel construction.

<3>No bottle no capping.

<4>Automatic stop when lack of bottle.

Certifications

Company Profile

<1> Standardized workshop of total 10,000 square meters. Different types of processing units,ensure the precision of parts.

<2>International certification, National Certificate of equipment verification, Verification Certificates of equipments: ISO9001:2001; CE Certificate, SGS, COC, etc.

<3>the equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline, and pneumatic, electrical and mechnical stability.

<4>the engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as per customers' requirements to save space.

<5>Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

<2>International certification, National Certificate of equipment verification, Verification Certificates of equipments: ISO9001:2001; CE Certificate, SGS, COC, etc.

<3>the equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline, and pneumatic, electrical and mechnical stability.

<4>the engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as per customers' requirements to save space.

<5>Professional installation team who can speak fluent English can help customers make benefits in a shortest time.