| Type: | Filling Machine |

|---|---|

| Brand Name: | Well Machinery |

| Packaging Material: | Wood |

| Packaging Type: | Bottles |

| Application: | Beverage |

| Condition: | New |

| After-sales Service Provided: | Engineers available to service machinery overseas |

| Certification: | CE |

| Weight: | 4.5T |

| Dimension(L*W*H): | 600*700*800 |

| Model Number: | DCGF |

| Place of Origin: | China (Mainland) |

| Power: | 3KW |

| Voltage: | 380V |

| Driven Type: | Electric |

| Automatic Grade: | Automatic |

| Product Name: | Carbonated soft drink filling machine/liquid drink packing line |

| Function: | Bottle Washing Filling Capping |

| Filling material: | Beverage |

| Usage: | Beverage Packaging |

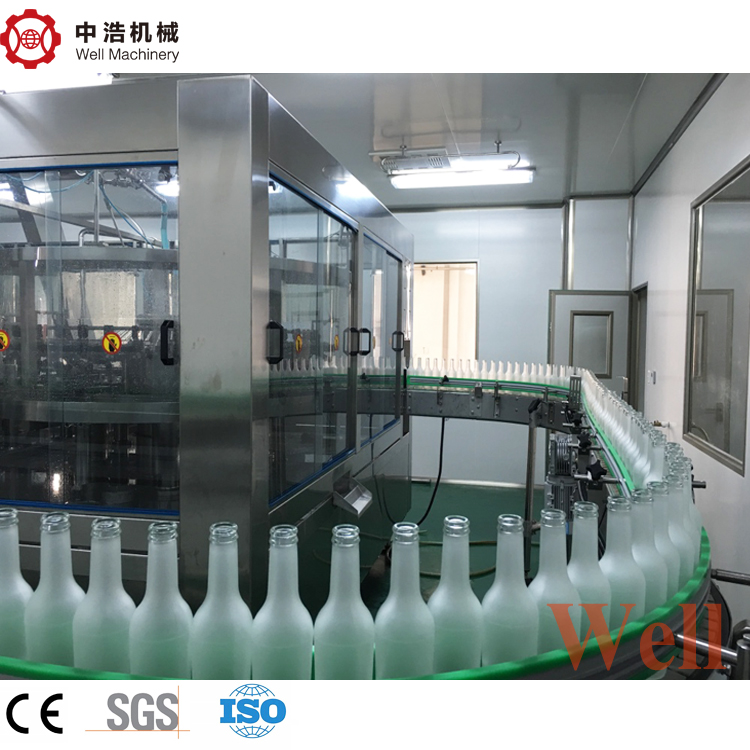

| Bottle type: | Glass Bottle |

| Warranty: | 3 Years |

| Processing Types: | Automatic Bottle Filling Sealing Machine |

| Control: | PLC+ Touch Screen |

Quick Details

Specifications

Products Description

Glass Bottle Carbonated Drink Filling Line

Details Images

Washing Heads

Glass Bottle Carbonated Drink Filling Line

It is Suitable for Glass Bottle Carbonated Beverage Filling, Such as Cola drink, Flavor Water, Gas Water, Sparkling Water, Soda Water etc.

the Filling Machine Monobloc Normally Includes Three Units: Rinsing Unit, Filling Unit, Capping Unit.

Filling Speed will be from 2000BPH-36000BPH

Capping Unit can be Designed Suitable for Crown Cap, Aluminum Cap.

Details Images

Washing Heads

1.into bottle way is air conveyor direct connection with bottle dial.

2. All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean.

3.304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing.

4.304/316 stainless steel washing pump make the machine more durable.

Filling Heads

1.304/316 Stainless steel high precision filling nozzle

2. Filling volume adjustable in fine rank, same liquid level after filling

3.All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

4.304/316 stainless steel filling pump

2. Filling volume adjustable in fine rank, same liquid level after filling

3.All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

4.304/316 stainless steel filling pump

Capping Heads

1.Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

2.All 304/316 stainless steel construction

3.No bottle no capping

- Automatic stop when lack of bottle

4. Capping effect is stable and reliable, Defective rate ≤0.2%

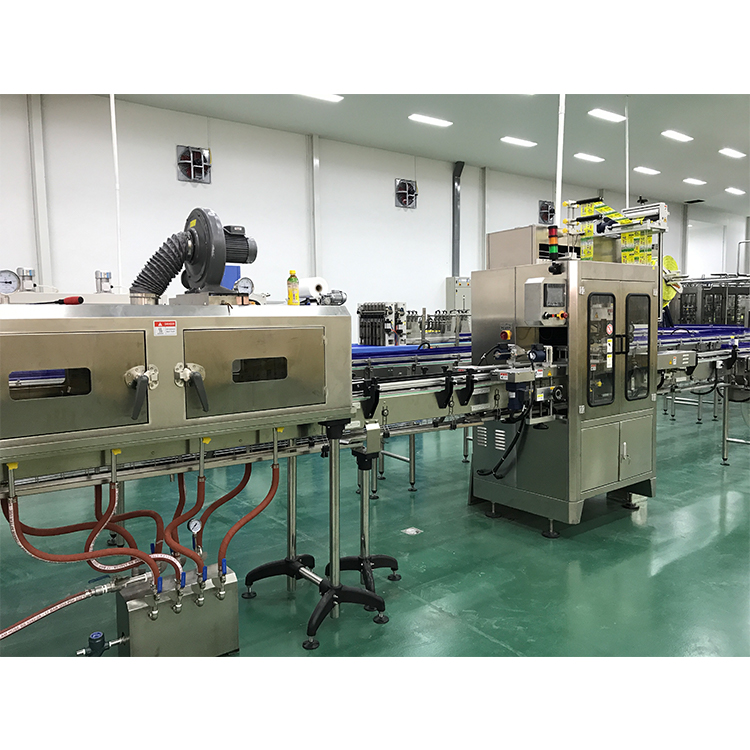

Flat Conveyor

1.Energy saving. High efficient. Adapt to customer factory layout

2.Special lubrication system, keep products clean, health, safety

3. Extended service life

- Electric eyes design keep whole line running safety and quickly

4. Overload protection mechanism to effectively ensure the safety of the machine

Auxiliary Equipment

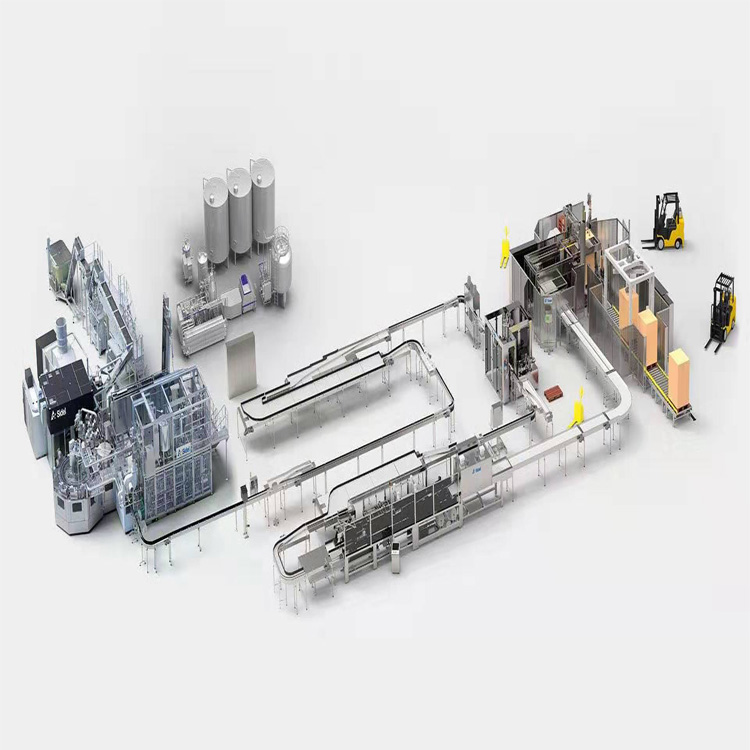

A Complete Glass Bottle Filling Line:

Carbonated Drink Mixer

Certifications

Company Profile

Well Machinery

Well Machinery

Auxiliary Equipment

A Complete Glass Bottle Filling Line:

Depalletizer-Filling Monoblock-Warming Tunnel-Labeling Unit-Packing Machine-Conveyor.

Carbonated Drink Mixer

1.Wide range of uses - the system can handle a wide range of products such as carbonated drinks, juice drinks, etc.

2.Easy power adjustment - easy adjustment of mixing ratio without having to replace parts.

3.Structural Hygiene - All parts in contact with fluids are of high quality stainless steel, all tanks are equipped with CIP ball for easy cleaning.

Warmer Bottle Machine.

Warmer Bottle Machine.

Automatic labeling machine.

1.Mainly for cooling and sterilization

2.the main parts of the machine are made of stainless steel, the top is designed to be openable

for easy maintenance and observation

for easy maintenance and observation

3.Nozzles are manufactured using U.S. Technology and spray water evenly

4.Conveyor belt adopts Rexnor technology, flat surface with small wear 5.Smooth and reliable operation with low energy consumption

Automatic labeling machine.

1.Heat shrink sleeve labeling machine

2.OPP Hot melt labeling machine

3.PVC label stick labeling machine

It adopts double driving structure which is a new and advanced driving device for the thermal shrink sleeve machine, that is,four-wheel driving, self-centering and balanced pressure of four wheels. It can achieve the good effect of transmission of labels smoothly, stably and rapidly.

PE film packaging machine.

1.PE film shrink wrapping machine

2.Half-tray shrink wrapping machine

3.Carton box packaging machine

It adopts the photoelectric sensor to detect online, gather signals which are controlled by PLC, and adopts piston as executable element, to realize product conveying, combination, film wrapping, cutting, heat& shrink, cool and finally get the finished product

Certifications

Company Profile

<1> Standardized workshop ofTotal 12,000 square meters.<2>with aMore than 30 professionals teamto design and develop, is a key professional enterprise, which integrates development,research, design, manufacture, technology service and marketing.

<3>Well Machinery follows ISO9001:2001; CE Certificate, SGS, COC, TUVInternational quality management system.

<4>the equipment will beTested and run for 24 hours beforeLeaving the factory, to ensure the smooth working of water pipeline,and pneumatic, electrical and mechnical stability.

<5>Sufficient stock of spare partsEnsures the timely delivery and supply of spare parts.

<6>Professional installation teamWho can speak fluent English can help customers make benefits in a shortest time.