| Type: | Filling Machine |

|---|---|

| Brand Name: | Well Machinery |

| Packaging Material: | Wood |

| Packaging Type: | Bottles |

| Application: | Beverage |

| Condition: | New |

| After-sales Service Provided: | Engineers available to service machinery overseas |

| Certification: | CE |

| Weight: | 4.5T |

| Dimension(L*W*H): | 600*700*800 |

| Model Number: | RCGF |

| Place of Origin: | China (Mainland) |

| Power: | 3KW |

| Voltage: | 380V |

| Driven Type: | Electric |

| Automatic Grade: | Automatic |

| Product Name: | Complete fruit juice production line/juice filling machine factory price |

| Function: | Bottle Washing Filling Capping |

| Filling material: | Juice |

| Usage: | Beverage Packaging |

| Bottle type: | PET Plastic Bottle |

| Warranty: | 3 Years |

| Processing Types: | Automatic Bottle Filling Sealing Machine |

| Control: | PLC+ Touch Screen |

Quick Details

Specifications

Products Description

this Filling Machine is Designed for Glass Bottle Filling Machine.

this Filling Machine is Designed for Glass Bottle Filling Machine.

It is Suitable for Glass Bottle Non-carbonated Beverage Filling, Such as various Juices, Flavor Water, Vitamin Water etc.

the Filling Machine Monobloc Normally Includes Three Units: Rinsing Unit, Filling Unit, Capping Unit.

Filling Speed will be from 2000BPH-36000BPH.

Capping Unit can be Designed Suitable for Crown Cap, Aluminum Cap & Twist Cap.

Details Images

Capping parts

Flat conveyor.

Company Profile

Washing parts

<1>All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean.

<2>304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

<3> 304/316 stainless steel washing pump make the machine more durable.

Filling Parts

<1> 304/316 Stainless steel high precision filling nozzle

<2> Filling volume adjustable in fine rank, same liquid level after filling

<3> All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

<4>Efficient spray nozzle rinse thoroughly and save water for flushing

Capping parts

<1> Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping <2> No bottle no capping

<3> Automatic stop when lack of bottle

<4>Capping effect is stable and reliable,Defective rate ≤0.2%.

Flat conveyor.

<1>Energy saving. High efficient. Adapt to customer factory layout

<2>Special lubrication system, keep products clean, health, safety <3>Extended service life

<4>Electric eyes design keep whole line running safety and quickly

Company Profile

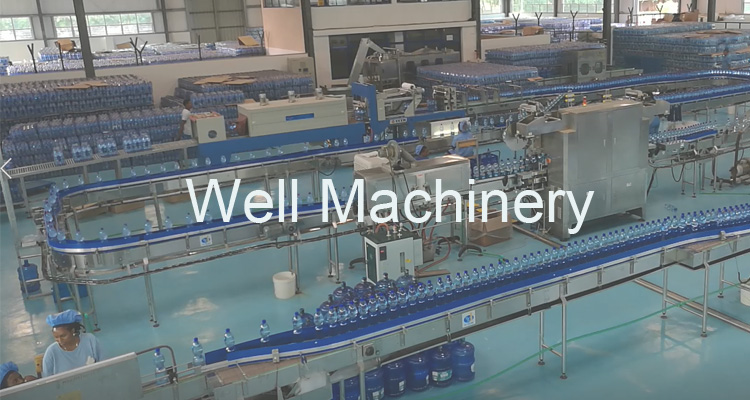

Well Machinery

<1>Standardized workshop ofTotal 12,000 squareMeters.

<2>with aMore than 30 professionals teamto design and develop, is a key professional enterprise, which integratesDevelopment,Research, design, manufacture, technology service and marketing.

<3>Well Machinery followsISO9001:2001; CE Certificate, SGS, COC, TUVInternational quality management system.

<4>the equipment will beTested and run for 24 hours beforeLeaving the factory, to ensure the smooth working of water pipeline,and pneumatic, electrical and mechnical stability.

<5>Sufficient stock of spare partsEnsures the timely delivery and supply of spare parts.

<6>Professional installation teamWho can speak fluent English can help customers make benefits in a shortest time.

Want to know more message, contact us with out hesitate! Inquiry us now!