| After-sales Service Provided: | Engineers available to service machinery overseas |

|---|---|

| Certification: | ISO,CE,EAC |

| Brand Name: | ALPA |

| Type: | Air Classifying Mill |

| Condition: | New |

| Warranty: | 1-Year Warranty |

| Weight: | Customized |

| Dimension(L*W*H): | Customized |

| Model Number: | CSM-V |

| Place of Origin: | China (Mainland) |

| Capacity(t/h): | 2-3000kg/h |

| Power(W): | Adjustable |

| Motor Type: | |

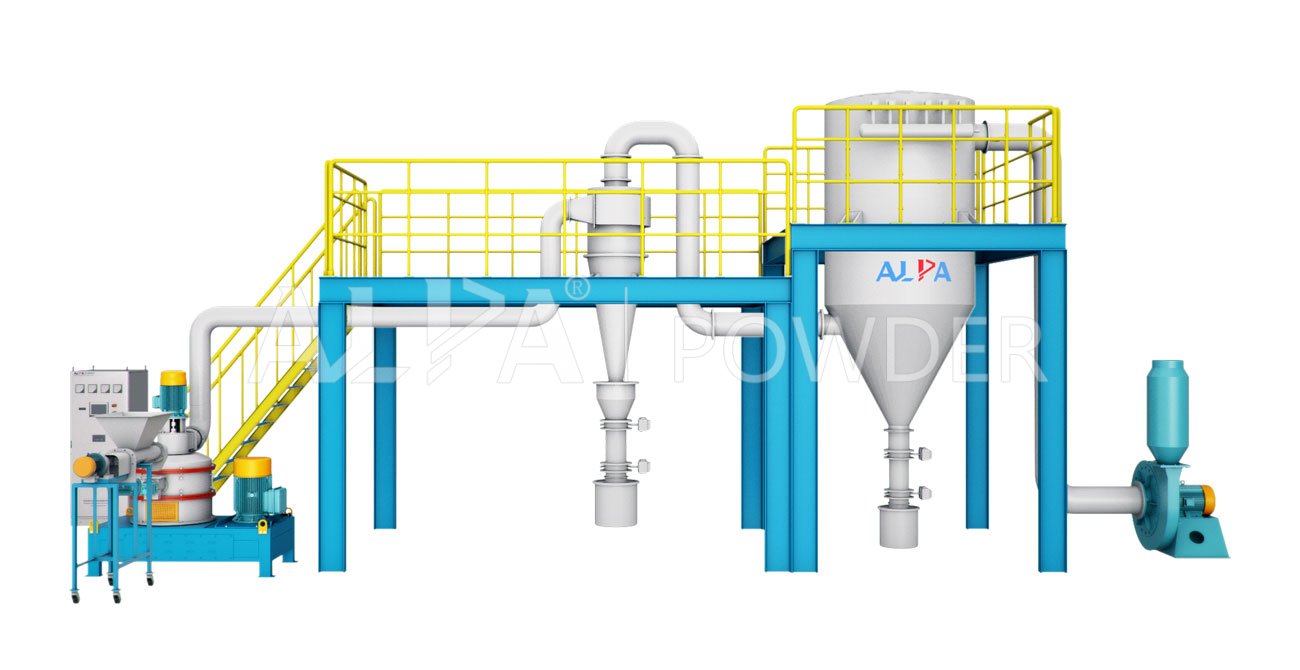

| Name: | CSM-V Air Classifying Mill |

| Type: | Air Classifier Mill |

| Feature: | Integration of grinding and classifying |

| Suitable for: | Mohs hardness < 5 |

Quick Details

Specifications

China ACM Air Classifier Mill for Carbon Black Powder Classifying Mill

Application:

Widely used in non-metallic minerals (Mohs hardness < 5), chemical, inorganic salts, pharmaceuticals, food, pigments, dyes, pesticides, battery materials, minerals, refractory materials and other industries.

Advantages:

1.Available D50:245μm

2.Integration of grinding and classifying, classifying wheel is adjusted to obtain ideal particle

3.Different types of grinding disc (pin, hammer, teeth or others) are used based on characteristics of materials to obtain different grinding forces and improve grinding efficiency.

4.Key parts like the hammer, gear ring and classifying wheel are made of ceramic such as aluminum oxide, zirconium oxide or silicon carbide, ensuring non-contact with metal throughout the grinding for high purity of the final product

5.High-temperature, low-temperature, normal-temperature, airtight cycle, Inert gas cycle designs are available, for different grinding requirements of different materials.

6.Optional explosion-proof design, meet the ultra-fine grinding processing requirements of flammable and explosive oxide materials

Working Principle:

Working Principle:

ALPA Service:

1.Service Commitment: We seek details for our service including before-sales consulting, sales process and after sales maintenance& service, we seeks every details get perfect. Intimate service, precise manufacture, reasonable price, satisfying our customers.

2.Centralized /Professional / Expert level services: Professional answer to customer's inquiry→Customized solution→Help customers to make construction and installation plan→Installation, commissioning and training→Regular inspection and visit

3.150+Service Engineers, ready to serve you at any time

4.Systematic and standardized process from service to delivery is safer and more efficient

5.Professional installation and commissioning to ensure smooth acceptance

6.Three quality assurances to ensure your production gets smooth

7.Continuously improving global services to guarantee availability at all times

8.Powerful hardware facilities provide strong support for the equipment manufacture

Application:

Widely used in non-metallic minerals (Mohs hardness < 5), chemical, inorganic salts, pharmaceuticals, food, pigments, dyes, pesticides, battery materials, minerals, refractory materials and other industries.

Advantages:

1.Available D50:245μm

2.Integration of grinding and classifying, classifying wheel is adjusted to obtain ideal particle

3.Different types of grinding disc (pin, hammer, teeth or others) are used based on characteristics of materials to obtain different grinding forces and improve grinding efficiency.

4.Key parts like the hammer, gear ring and classifying wheel are made of ceramic such as aluminum oxide, zirconium oxide or silicon carbide, ensuring non-contact with metal throughout the grinding for high purity of the final product

5.High-temperature, low-temperature, normal-temperature, airtight cycle, Inert gas cycle designs are available, for different grinding requirements of different materials.

6.Optional explosion-proof design, meet the ultra-fine grinding processing requirements of flammable and explosive oxide materials

the material is evenly fed into the grinding chamber by the feeding system, strongly impacted by the high-speed rotating grinding disc. At the same time, it is subjected to centrifugal force and collides with the grinding ring gear, and is subjected to various comprehensive forces such as shearing, friction and collision to finished grinding. the grinded material moves to the classifying zone with the airflow. the classifier is adjusted by frequency conversion, separates the coarse and fine materials, the product that meet the fineness requirement enters the cyclone collector and the dust collector with the airflow, and the coarse powders return to the classifying zone, secondary grinding.

Product pictures:ALPA Service:

1.Service Commitment: We seek details for our service including before-sales consulting, sales process and after sales maintenance& service, we seeks every details get perfect. Intimate service, precise manufacture, reasonable price, satisfying our customers.

2.Centralized /Professional / Expert level services: Professional answer to customer's inquiry→Customized solution→Help customers to make construction and installation plan→Installation, commissioning and training→Regular inspection and visit

3.150+Service Engineers, ready to serve you at any time

4.Systematic and standardized process from service to delivery is safer and more efficient

5.Professional installation and commissioning to ensure smooth acceptance

6.Three quality assurances to ensure your production gets smooth

7.Continuously improving global services to guarantee availability at all times

8.Powerful hardware facilities provide strong support for the equipment manufacture