| After-sales Service Provided: | Engineers available to service machinery overseas |

|---|---|

| Certification: | ISO,CE,EAC |

| Brand Name: | ALPA |

| Type: | Hammer Mill |

| Condition: | New |

| Warranty: | 1-Year Warranty |

| Weight: | Customized |

| Dimension(L*W*H): | Customized |

| Model Number: | CUM-F |

| Place of Origin: | China (Mainland) |

| Capacity(t/h): | 50-10000 |

| Power(W): | Adjustable |

| Motor Type: | |

| Name: | CUM-F Hammer Mill |

| Product Size(um): | D50:10-50um |

| Sieve hole size: | 0.2mm-3mm |

| Control: | PLC control system |

| Product Size(mesh): | 20~325 |

Quick Details

Specifications

Fine Grinding Imppact Hammer Mill with Cyclone

Application: Widely used in chemical, inorganic salt, medicine, food, pigments, dyes, pesticides, battery materials, minerals, refractory materials and other industries.

Features:

1.Available D50:10850μm

2.Lower installation power, wide application, high cost-performance

3.Grinding is in closed system, low dust and noise, clean and environmentally friendly production process

4.PLC control system, easy operation

5.High-temperature, low-temperature, normal-temperature, airtight cycle, Inert gas cycle designs are available, for different grinding requirements of different materials

6.Optional explosion-proof design, meet the ultra-fine grinding processing requirements of flammable and explosive oxide materials

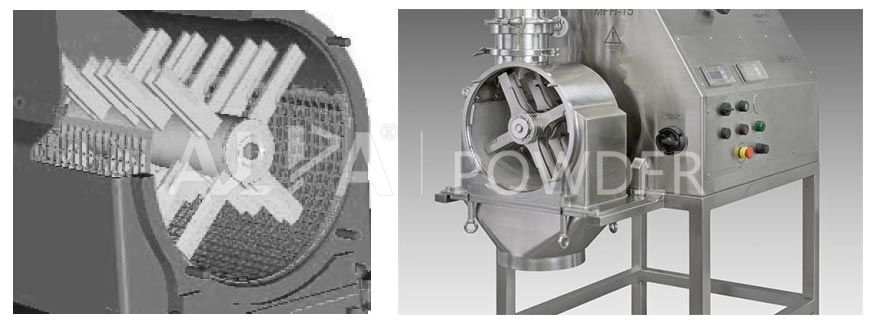

Working Principle:

the material is evenly fed into the grinding chamber by the feeding system, strongly impacted by the high-speed rotating disc. At the same time, it is subjected to various comprehensive forces such as friction, shearing and collision between the static disc and the ring gear to grind material. the moving disc and static disc can be combined in different structural forms according to nature of material to meet the grinding requirements of different materials.

Application: Widely used in chemical, inorganic salt, medicine, food, pigments, dyes, pesticides, battery materials, minerals, refractory materials and other industries.

Features:

1.Available D50:10850μm

2.Lower installation power, wide application, high cost-performance

3.Grinding is in closed system, low dust and noise, clean and environmentally friendly production process

4.PLC control system, easy operation

5.High-temperature, low-temperature, normal-temperature, airtight cycle, Inert gas cycle designs are available, for different grinding requirements of different materials

6.Optional explosion-proof design, meet the ultra-fine grinding processing requirements of flammable and explosive oxide materials

Working Principle:

the material is evenly fed into the grinding chamber by the feeding system, strongly impacted by the high-speed rotating disc. At the same time, it is subjected to various comprehensive forces such as friction, shearing and collision between the static disc and the ring gear to grind material. the moving disc and static disc can be combined in different structural forms according to nature of material to meet the grinding requirements of different materials.

WHO CHOOSE US

Common choice of many well-known companies

by 2018,37World top 500 companies,89Chinese top 500 companies,169National key laboratories and

Engineering technology research centers have selectedALPA.

More than3,000Customers have chosen us