| After-sales Service Provided: | Engineers available to service machinery overseas |

|---|---|

| Certification: | ISO,CE,EAC |

| Brand Name: | ALPA |

| Type: | Hammer Mill |

| Condition: | New |

| Warranty: | 1-Year Warranty |

| Weight: | Customized |

| Dimension(L*W*H): | Customized |

| Model Number: | CUM-F |

| Place of Origin: | China (Mainland) |

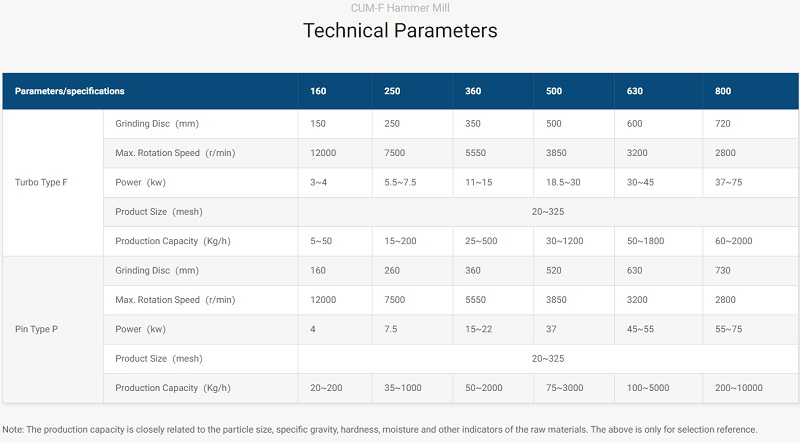

| Capacity(t/h): | 5-10000kg/h |

| Power(W): | Adjustable |

| Motor Type: | |

| Name: | CUM-F Hammer Mill |

| Product Size(um): | D50:10-850um |

| Sieve hole: | 0.2mm-3mm |

| Power(kw): | 3-75 |

| Product Size(mesh): | 20~325 |

Quick Details

Specifications

Small Occupation Hammer Mill Grinder Pulverizer Machine

Application:Widely used in chemical, inorganic salt, medicine, food, pigments, dyes, pesticides, battery materials, minerals, refractory materials and other industries.

Features:

1.Available D50:10850μm

2.Different installation combinations, applicable to different process requirements

3.Grinding is in closed system, low dust and noise, clean and environmentally friendly production process

4.PLC control system, easy operation

5.Optional explosion-proof design, meet the ultra-fine grinding processing requirements of flammable and explosive oxide materials

6.High-temperature, low-temperature, normal-temperature, airtight cycle, Inert gas cycle designs are available, for different grinding requirements of different materials.

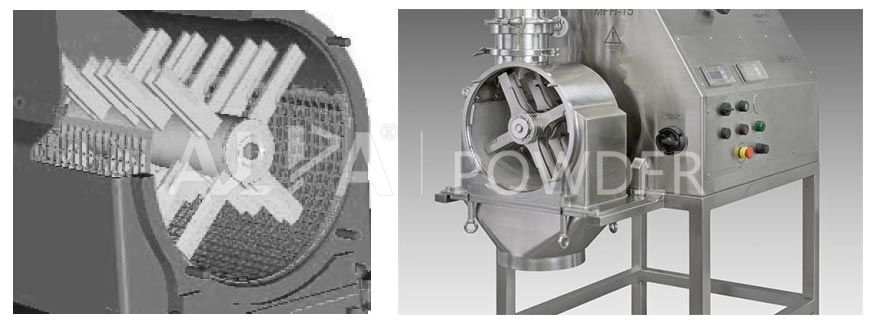

Working Principle:

the material is evenly fed into the grinding chamber by the feeding system, strongly impacted by the high-speed rotating disc. At the same time, it is subjected to various comprehensive forces such as friction, shearing and collision between the static disc and the ring gear to grind material. the moving disc and static disc can be combined in different structural forms according to nature of material to meet the grinding requirements of different materials.

Application:Widely used in chemical, inorganic salt, medicine, food, pigments, dyes, pesticides, battery materials, minerals, refractory materials and other industries.

Features:

1.Available D50:10850μm

2.Different installation combinations, applicable to different process requirements

3.Grinding is in closed system, low dust and noise, clean and environmentally friendly production process

4.PLC control system, easy operation

5.Optional explosion-proof design, meet the ultra-fine grinding processing requirements of flammable and explosive oxide materials

6.High-temperature, low-temperature, normal-temperature, airtight cycle, Inert gas cycle designs are available, for different grinding requirements of different materials.

Working Principle:

the material is evenly fed into the grinding chamber by the feeding system, strongly impacted by the high-speed rotating disc. At the same time, it is subjected to various comprehensive forces such as friction, shearing and collision between the static disc and the ring gear to grind material. the moving disc and static disc can be combined in different structural forms according to nature of material to meet the grinding requirements of different materials.

Q: What service do you supply?

A: 1). We offer consultancy forProject feasibility assessment, process flow definition, preliminary layout and factory building plan, project budget, project time schedule, etc.

2). We supplySample processing testsin our test station where are equipped with our various machine products, to help clients compare performances of different types of machines or process.

3). We supplyProject engineering, automation engineering and civil engineering.

4). We send engineers to the clients' project site andOffer on-site technical instruction and supervisionduring the machine installation, commissioning and test run.

Q:how can I trust on your quality?

A: 1). All of the machine beTested successfullyin Weifang workshopBefore shipment.

2). We supplyOne year warrantyfor all equipment andLifelong after-sales service.

3). We canTest your materialin our equipmentBeafore place the order, to ensure our equipment is suitable for your project.

4). Our engineers willGo to your factory to install and debug the equipment, they will not be back until these equipment can produce qualified products.

Q:Does your company provide Engineers Abroad Service?

A: Sure, we provide it. and we can provideFree trainingfor on-site workers.

Q:how to train our staff about operation and maintenance?

A: We willProvide detailed technical instructivePictures to teach them for the operation and maintenance. In addition, our engineers for guide assembly will teach your staffon site.