| After-sales Service Provided: | Engineers available to service machinery overseas |

|---|---|

| Certification: | ISO,CE,EAC |

| Brand Name: | ALPA |

| Type: | Ring Roller Mill |

| Condition: | New |

| Warranty: | 1-Year Warranty |

| Weight: | Customized |

| Dimension(L*W*H): | Customized |

| Model Number: | RLM |

| Place of Origin: | China (Mainland) |

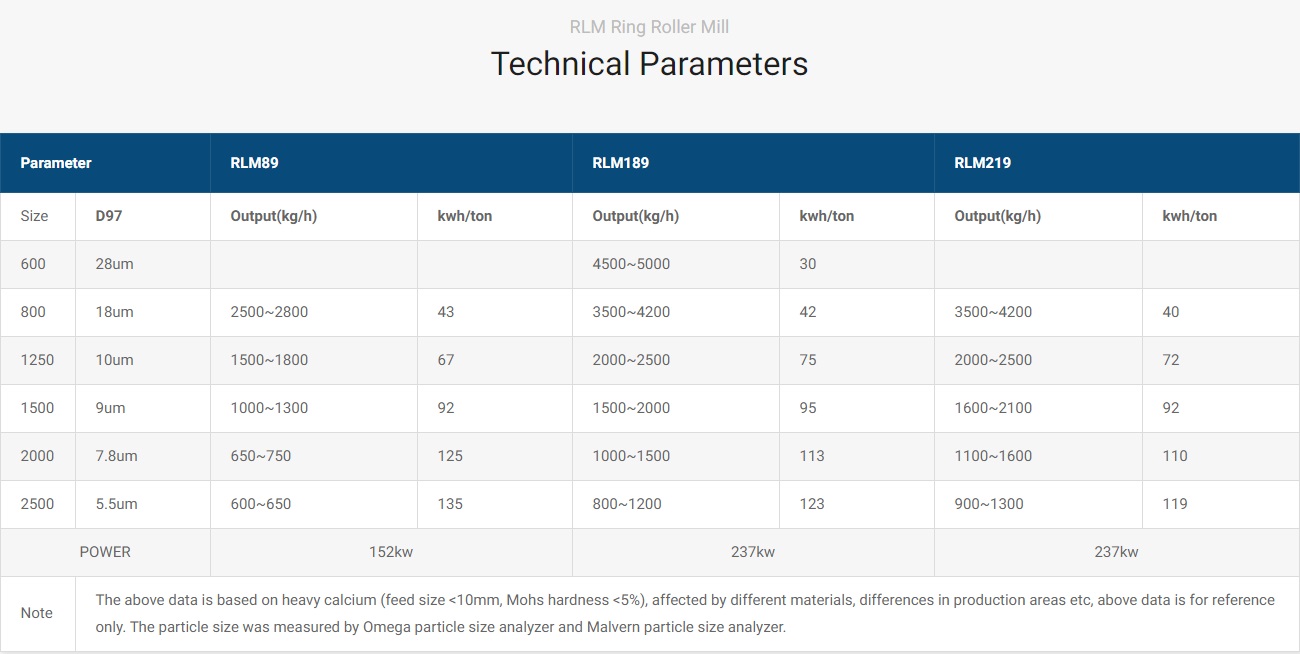

| Capacity(t/h): | 600-5000kg/h |

| Power(W): | Adjustable |

| Motor Type: | |

| Name: | RLM Ring Roller Mill |

| Product Size(um): | D50:1.5-45um |

| Application: | Suitable for non-metallic mineral |

Quick Details

Specifications

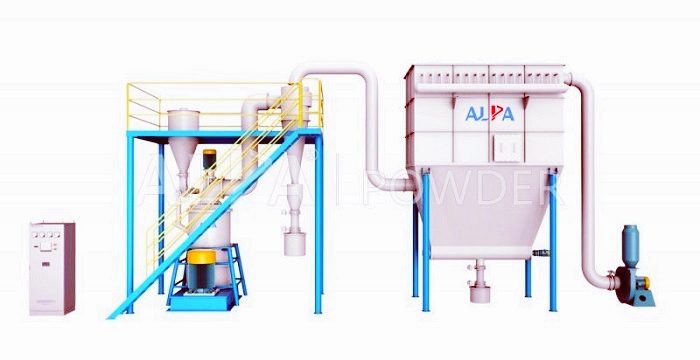

Automatic Impact Roller Grinding Mill Machine for Sale

Application:Widely used in calcium carbonate (calcite, marble, limestone, chalk), barite, kaolin, dolomite, magnesite, alumina, superfine cement, slag, steel slag and other industries.

Features:

1.Available D50:1.545μm

2.It is equipped with classifying wheel frequency control, which can adjust the granularity of the product without stopping the machine

3.Explosion-proof design can be selected to meet the requirements of ultra-fine grinding processing of flammable and explosive oxide materials

4.PLC control system, easy operation

5.Grinding is in closed system, low dust and noise, clean and environmentally friendly production process

Working Principle:

Application:Widely used in calcium carbonate (calcite, marble, limestone, chalk), barite, kaolin, dolomite, magnesite, alumina, superfine cement, slag, steel slag and other industries.

Features:

1.Available D50:1.545μm

2.It is equipped with classifying wheel frequency control, which can adjust the granularity of the product without stopping the machine

3.Explosion-proof design can be selected to meet the requirements of ultra-fine grinding processing of flammable and explosive oxide materials

4.PLC control system, easy operation

5.Grinding is in closed system, low dust and noise, clean and environmentally friendly production process

Working Principle:

Roller mills(micro powder roller mill,fine roller mill,ring roller mill,roller grinding machine,automatic roller mill,three/four roller/rolling mill) are mills that use cylindrical rollers, either in opposing pairs or against flat plates, to crush or grind various materials, such as grain, ore, gravel, plastic, and others. Roller grain mills are an alternative to traditional millstone arrangements in gristmills. Roller mills for rock complement other types of mills, such as ball mills and hammermills, in such industries as the mining and processing of ore and construction aggregate; cement milling; and recycling.

Transmission device connects with main shaft. the top of shaft connects with rotor structure. the rotor structure has peripheral shaft. Peripheral shaft is installed with roller. When the main shaft starts to rotate, peripheral shaft rotates too, which would make the rollers revolve around main shaft and also rotate round peripheral shaft. the roller would create strong centrifugal force during the rotation and revolving, and grind material with stator. the ground material would fall down to the distribution plate. the distribution plate and the main shaft would rotate at the same time, and bring material to the round ring. under negative pressure, it would go along the distribution ring to the classifier chamber. Qualified fine powder would go through the classifier wheel and into the collector, while coarse powder would fall down back to the milling chamber for further grinding.

Shandong ALPA Powder Technology Co., Ltd.

(abbreviation: ALPA / Equity Code: 171033)

the WORLD'S LEADING SUPPLIER of

ULTRA-FINE POWDER SOLUTIONS

ALPA was founded in 1999.Focus on ultra-fine ultra-pure crushing and classifying research, powder shape control, powder surface modification, and system integration of powder engineering equipment.

in the fields of ultrafine grinding and classification in the pharmaceutical, food, chemical, mineral, new materials, solid waste treatment and other industries, ALPA has mature and fully customized solutions and helps you design the ideal system to meet your needs.