| After-sales Service Provided: | Engineers available to service machinery overseas |

|---|---|

| Certification: | ISO,CE,EAC |

| Brand Name: | ALPA |

| Type: | Vibration Mill |

| Condition: | New |

| Warranty: | 1-Year Warranty |

| Weight: | Customized |

| Dimension(L*W*H): | Customized |

| Model Number: | MZ |

| Place of Origin: | China (Mainland) |

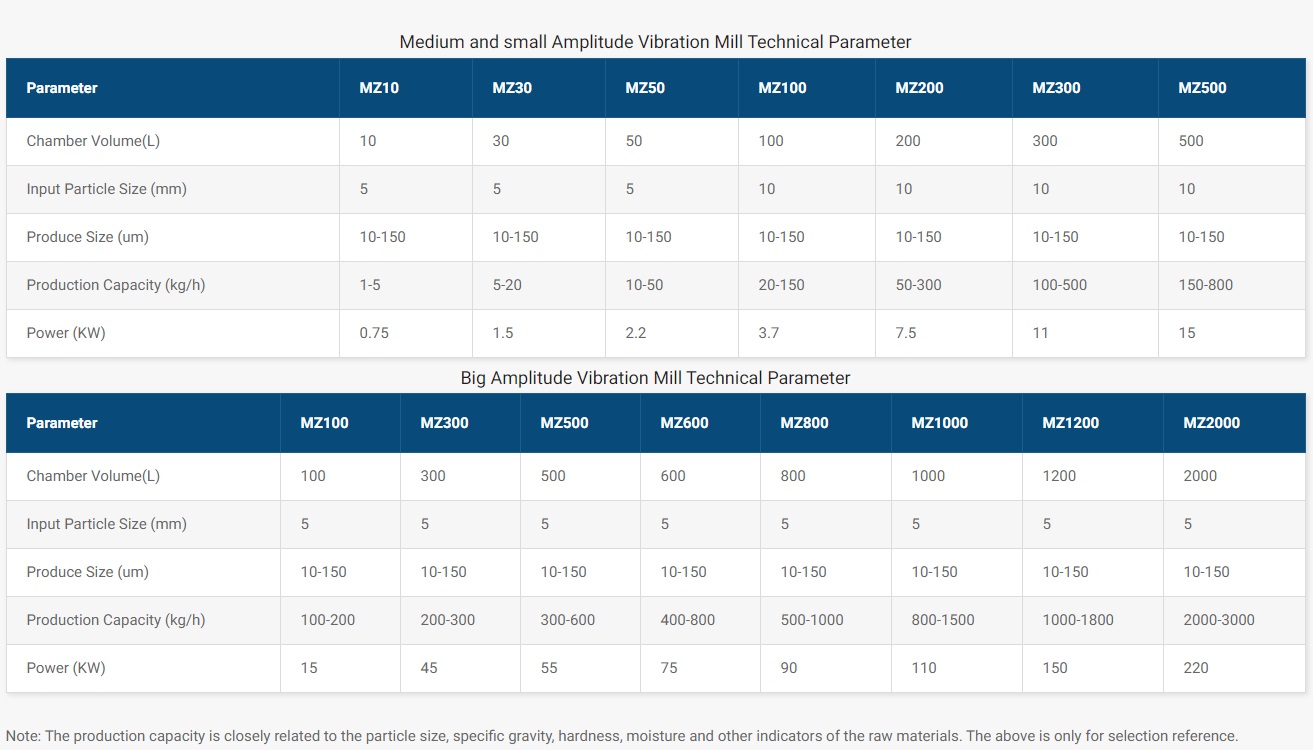

| Capacity(t/h): | 1-3000kg/h |

| Power(W): | Adjustable |

| Motor Type: | |

| Name: | MZ Vibration Mill |

| Product Size(um): | D50:2.5-150um |

| Material: | Moh's hardness below 9 |

| Chamber Volume(L): | 10-2000 |

| Input Particle Size (mm): | 5-10 |

| Production Capacity (kg/h): | 1-3000 |

Quick Details

Specifications

China Herb Vibrating Tube Vibration Mill for Sale

Application: Widely used in chemical, mineral, building materials, metallurgy, abrasives, ceramics, refractory materials, food, health care products, new materials and other industries.

Features:

1.Available D50:2.5150μm

2.Suitable for grinding raw materials with Moh's hardness below 9

3.Particle size can be adjustable by adjusting parameters such as grinding medium, amplitude, and frequency. the finer powder can be given in conjunction with classifier in series

4.Grinding media and liners can be made of special materials such as high manganese steel, high chromium steel, stainless steel, alumina, zirconia, quartz, etc., which are wear resistant and less pollution

5.Explosion-proof design can be selected to meet the requirements of ultra-fine grinding processing of flammable and explosive oxide materials

Working Principle:

with the high-speed vibrator or vibration motor, the grinding media (pins, cylpebs or balls) would vibrate in high frequency, high-speed rotating and slow revolving, which would impact, rub and shear materials around them and make them into fine powder and mix them evenly.

Application: Widely used in chemical, mineral, building materials, metallurgy, abrasives, ceramics, refractory materials, food, health care products, new materials and other industries.

Features:

1.Available D50:2.5150μm

2.Suitable for grinding raw materials with Moh's hardness below 9

3.Particle size can be adjustable by adjusting parameters such as grinding medium, amplitude, and frequency. the finer powder can be given in conjunction with classifier in series

4.Grinding media and liners can be made of special materials such as high manganese steel, high chromium steel, stainless steel, alumina, zirconia, quartz, etc., which are wear resistant and less pollution

5.Explosion-proof design can be selected to meet the requirements of ultra-fine grinding processing of flammable and explosive oxide materials

Working Principle:

with the high-speed vibrator or vibration motor, the grinding media (pins, cylpebs or balls) would vibrate in high frequency, high-speed rotating and slow revolving, which would impact, rub and shear materials around them and make them into fine powder and mix them evenly.

Shandong ALPA Powder Technology Co., Ltd.

(abbreviation: ALPA / Equity Code: 171033)

the WORLD'S LEADING SUPPLIER of

ULTRA-FINE POWDER SOLUTIONS

ALPA was founded in 1999.Focus on ultra-fine ultra-pure crushing and classifying research, powder shape control, powder surface modification, and system integration of powder engineering equipment.

in the fields of ultrafine grinding and classification in the pharmaceutical, food, chemical, mineral, new materials, solid waste treatment and other industries, ALPA has mature and fully customized solutions and helps you design the ideal system to meet your needs.

Q: What service do you supply?

A: 1). We offer consultancy for project feasibility assessment, process flow definition, preliminary layout and factory building plan, project budget, project time schedule, etc.

2). We supply sample processing tests in our test station where are equipped with our various machine products, to help clients compare performances of different types of machines or process.

3). We supply project engineering, automation engineering and civil engineering.

4). We send engineers to the clients' project site and offer on-site technical instruction and supervision during the machine installation, commissioning and test run.

Q:how can I trust on your quality?

A: 1). All of the machine be tested successfully in Weifang workshop before shipment.

2). We supply one year warranty for all equipment and lifelong after-sales service.

3). We can test your material in our equipment before place the order, to ensure our equipment is suitable for your project.

4). Our engineers will go to your factory to install and debug the equipment, they will not be back until these equipment can produce qualified products.

Q:Does your company provide Engineers Abroad Service?

A: Sure, we provide it. and we can provide free training for on-site workers.

Q:how to train our staff about operation and maintenance?

A: We will provide detailed technical instructive pictures to teach them for the operation and maintenance. In addition, our engineers for guide assembly will teach your staff on site.