| After-sales Service Provided: | Engineers available to service machinery overseas |

|---|---|

| Certification: | ISO,CE,EAC |

| Brand Name: | ALPA |

| Type: | Vibration Mill |

| Condition: | New |

| Warranty: | 1-Year Warranty |

| Weight: | Customized |

| Dimension(L*W*H): | Customized |

| Model Number: | MZ |

| Place of Origin: | China (Mainland) |

| Power(W): | Adjustable |

| Motor Type: | |

| Name: | MZ Vibration Mill |

| Product Size(um): | D50:2.5-150um |

| Material: | Moh's hardness below 9 |

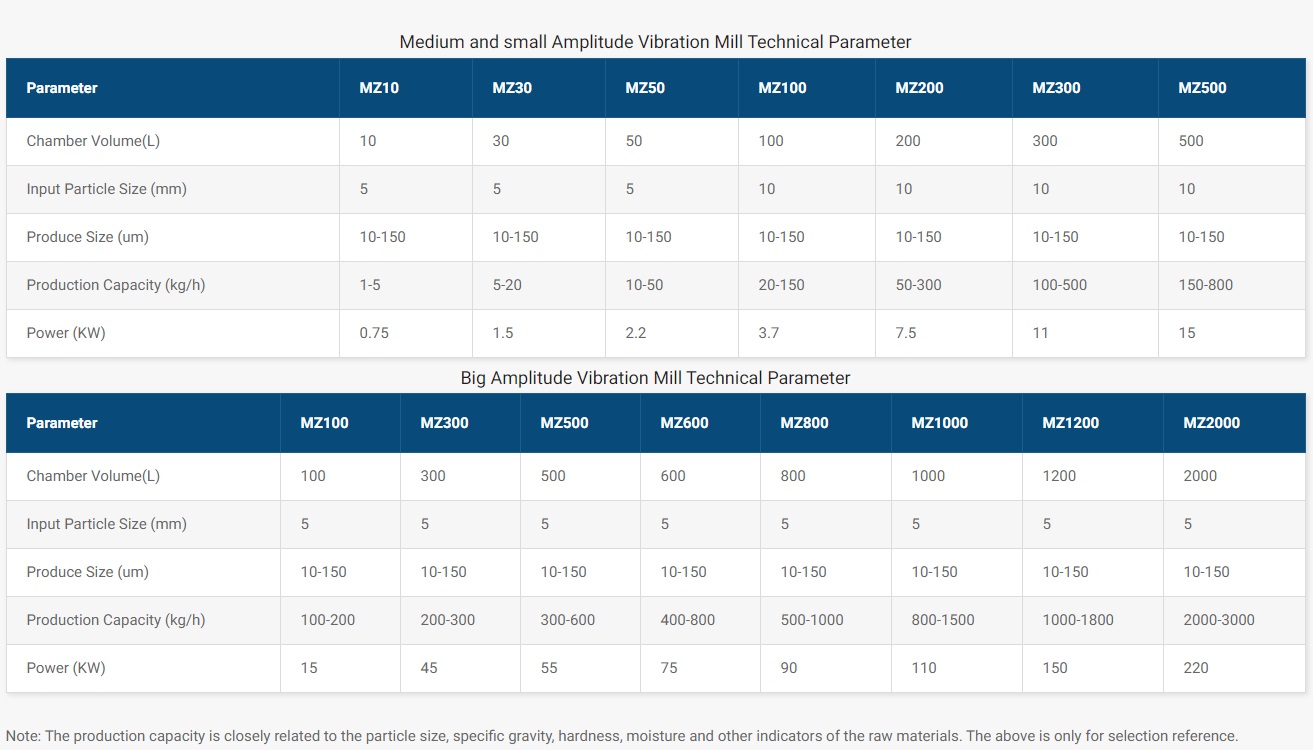

| Chamber Volume(L): | 10-2000 |

Quick Details

Specifications

Ultrafine Grinding Milling Machine Vibration Mill

Application: Widely used in chemical, mineral, building materials, metallurgy, abrasives, ceramics, refractory materials, food, health care products, new materials and other industries.

Features:

1.Available D50:2.5150μm

2.PLC control system, easy operation

3.Suitable for powder mixing, surface coating,mechanical chemical modification, etc

4.for heat sensitive and low melting materials, it can be crushed by water cooling or strong cooling

5.Explosion-proof design can be selected to meet the requirements of ultra-fine grinding processing of flammable and explosive oxide materials.

Working Principle:

with the high-speed vibrator or vibration motor, the grinding media (pins, cylpebs or balls) would vibrate in high frequency, high-speed rotating and slow revolving, which would impact, rub and shear materials around them and make them into fine powder and mix them evenly.

Application: Widely used in chemical, mineral, building materials, metallurgy, abrasives, ceramics, refractory materials, food, health care products, new materials and other industries.

Features:

1.Available D50:2.5150μm

2.PLC control system, easy operation

3.Suitable for powder mixing, surface coating,mechanical chemical modification, etc

4.for heat sensitive and low melting materials, it can be crushed by water cooling or strong cooling

5.Explosion-proof design can be selected to meet the requirements of ultra-fine grinding processing of flammable and explosive oxide materials.

Working Principle:

with the high-speed vibrator or vibration motor, the grinding media (pins, cylpebs or balls) would vibrate in high frequency, high-speed rotating and slow revolving, which would impact, rub and shear materials around them and make them into fine powder and mix them evenly.

Shandong ALPA Powder Technology Co., Ltd.

(abbreviation: ALPA / Equity Code: 171033)

the WORLD'S LEADING SUPPLIER of

ULTRA-FINE POWDER SOLUTIONS

ALPA was founded in 1999.Focus on ultra-fine ultra-pure crushing and classifying research, powder shape control, powder surface modification, and system integration of powder engineering equipment.

in the fields of ultrafine grinding and classification in the pharmaceutical, food, chemical, mineral, new materials, solid waste treatment and other industries, ALPA has mature and fully customized solutions and helps you design the ideal system to meet your needs.

in the fields of ultrafine grinding and classification in the pharmaceutical, food, chemical, mineral, new materials, solid waste treatment and other industries, ALPA has mature and fully customized solutions and helps you design the ideal system to meet your needs.