| After-sales Service Provided: | Engineers available to service machinery overseas |

|---|---|

| Certification: | ISO,CE,EAC |

| Brand Name: | ALPA |

| Type: | Vibration Mill |

| Condition: | New |

| Warranty: | 1-Year Warranty |

| Weight: | Customized |

| Dimension(L*W*H): | Customized |

| Model Number: | MZ |

| Place of Origin: | China (Mainland) |

| Capacity(t/h): | 1-3000kg/h |

| Power(W): | Adjustable |

| Motor Type: | |

| Name: | MZ Vibration Mill |

| Product Size(um): | D50:2.5-150um |

| Material: | Moh's hardness below 9 |

| Control: | PLC control system |

Quick Details

Specifications

Industrial Herbal Grinding Machine Herb Grinder Mill Machine for Sale

Application:

Suitable for the grinding of toughness, fiber, sponge, high oil and high sugar content of materials which are difficult to be grinded by general grinders. Also for hardness and brittle materials. Widely used in Chinese herbal medicine, medicine, food, health products, cosmetics and other industries.

Features:

1.Available D50:2.5150μm

2.Grinding media and liners can be made of special materials such as high manganese steel, high chromium steel, stainless steel, alumina, zirconia, quartz, etc., which are wear resistant and less pollution

3.Grinding media and liners can be made of special materials such as high manganese steel, high chromium steel, stainless steel, alumina, zirconia, quartz, etc., which are wear resistant and less pollution

4.Suitable for powder mixing, surface coating,mechanical chemical modification, etc

5.Explosion-proof design can be selected to meet the requirements of ultra-fine grinding processing of flammable and explosive oxide materials.

6.Grinding chamber with cooling jacket, Adjust the temperature and flow of water to control the temperature of the grinding chamber; or configure a strong cooling system, operating at temperature of -30C0C

Working Principle:

by strong vibration of the vibration source, the material in the grinding chamber is in the fluidized state, and is subjected to the high-strength impact of the grinding rod, such as collision, cutting, grinding and squeezing, so that the material can reach the micron pulverization or cell wall disruption in a short time.

at same time, the grinder can also be used as a precision mixer and a coating modifier. by adjusting the intensity of vibration, it is convenient to control the fineness of the material to be grinded.

Dry and wet pulverizing operations are both available. Meet GMP requirements, easy to assemble and disassemble, suitable for refueling operations.

It has various working configurations such as normal temperature, water cooling, low temperature, ultra-low temperature, anti-oxidation and anti-explosion, which can reduce the temperature in the grinding chamber and facilitate the crushing of heat-sensitive materials.

Widely used in Chinese herbal medicine, medicine, food, health products, cosmetics and other industries. It is a grinder with simple process and high cost performance.

Application:

Suitable for the grinding of toughness, fiber, sponge, high oil and high sugar content of materials which are difficult to be grinded by general grinders. Also for hardness and brittle materials. Widely used in Chinese herbal medicine, medicine, food, health products, cosmetics and other industries.

Features:

1.Available D50:2.5150μm

2.Grinding media and liners can be made of special materials such as high manganese steel, high chromium steel, stainless steel, alumina, zirconia, quartz, etc., which are wear resistant and less pollution

3.Grinding media and liners can be made of special materials such as high manganese steel, high chromium steel, stainless steel, alumina, zirconia, quartz, etc., which are wear resistant and less pollution

4.Suitable for powder mixing, surface coating,mechanical chemical modification, etc

5.Explosion-proof design can be selected to meet the requirements of ultra-fine grinding processing of flammable and explosive oxide materials.

6.Grinding chamber with cooling jacket, Adjust the temperature and flow of water to control the temperature of the grinding chamber; or configure a strong cooling system, operating at temperature of -30C0C

Working Principle:

by strong vibration of the vibration source, the material in the grinding chamber is in the fluidized state, and is subjected to the high-strength impact of the grinding rod, such as collision, cutting, grinding and squeezing, so that the material can reach the micron pulverization or cell wall disruption in a short time.

at same time, the grinder can also be used as a precision mixer and a coating modifier. by adjusting the intensity of vibration, it is convenient to control the fineness of the material to be grinded.

Dry and wet pulverizing operations are both available. Meet GMP requirements, easy to assemble and disassemble, suitable for refueling operations.

It has various working configurations such as normal temperature, water cooling, low temperature, ultra-low temperature, anti-oxidation and anti-explosion, which can reduce the temperature in the grinding chamber and facilitate the crushing of heat-sensitive materials.

Widely used in Chinese herbal medicine, medicine, food, health products, cosmetics and other industries. It is a grinder with simple process and high cost performance.

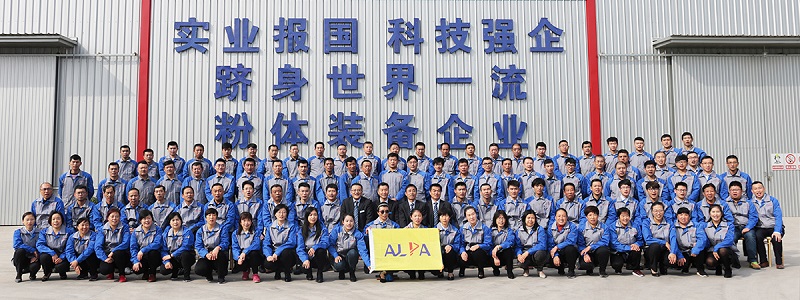

Company Profile:

ALPA was founded in 1999.Focus on ultra-fine ultra-pure crushing and classifying research, powder shape control, powder surface modification, and system integration of powder engineering equipment.

ALPA was founded in 1999.Focus on ultra-fine ultra-pure crushing and classifying research, powder shape control, powder surface modification, and system integration of powder engineering equipment.

in the fields of ultrafine grinding and classification in the pharmaceutical, food, chemical, mineral, new materials, solid waste treatment and other industries, ALPA has mature and fully customized solutions and helps you design the ideal system to meet your needs.