| After-sales Service Provided: | Engineers available to service machinery overseas |

|---|---|

| Certification: | ISO,CE,EAC |

| Brand Name: | ALPA |

| Type: | Air Classifier |

| Condition: | New |

| Warranty: | 1-Year Warranty |

| Weight: | Customized |

| Dimension(L*W*H): | Customized |

| Model Number: | FL/ITC |

| Place of Origin: | China (Mainland) |

| Capacity(t/h): | 20-30000kg/h |

| Power(W): | Adjustable |

| Motor Type: | |

| Name: | FL/ITC Vertical Air Classifier |

| Feature: | Single Rotor/Multiple Rotor |

| Particle Size: | D50:2-45um |

| Classifying efficiency: | 60%-90% |

| Noise: | <76dB(A) |

| Control: | PLC control system |

Quick Details

Specifications

China Super Air Classifier Manufacturers Cyclone Separator Design

Application:

Widely used in chemical industry, minerals (especially suitable for non-mineral materials classifying, such as calcium carbonate, kaolin, quartz, talc, mica), metallurgy, abrasives, ceramics, refractory materials, medicines, pesticides, food, health products, new materials, etc. Industry.

Features:

1.Available D50:2-45μm

2.Suitable for precise classifying of dry micron material

3.Classifying efficiency (extraction ratio) can be 60%90%

4.the linear velocity of horizontally installed classifying wheels is up to 70m/s

5.System equipped with muffler operating under negative pressure, meet environmental requirements,noise <76dB(A)

6.PLC control system, easy operation

7.Optional explosion-proof design, can also be upgraded to a nitrogen circulation system to meet the processing needs of flammable and explosive oxide materials

Working Principle:

Application:

Widely used in chemical industry, minerals (especially suitable for non-mineral materials classifying, such as calcium carbonate, kaolin, quartz, talc, mica), metallurgy, abrasives, ceramics, refractory materials, medicines, pesticides, food, health products, new materials, etc. Industry.

Features:

1.Available D50:2-45μm

2.Suitable for precise classifying of dry micron material

3.Classifying efficiency (extraction ratio) can be 60%90%

4.the linear velocity of horizontally installed classifying wheels is up to 70m/s

5.System equipped with muffler operating under negative pressure, meet environmental requirements,noise <76dB(A)

6.PLC control system, easy operation

7.Optional explosion-proof design, can also be upgraded to a nitrogen circulation system to meet the processing needs of flammable and explosive oxide materials

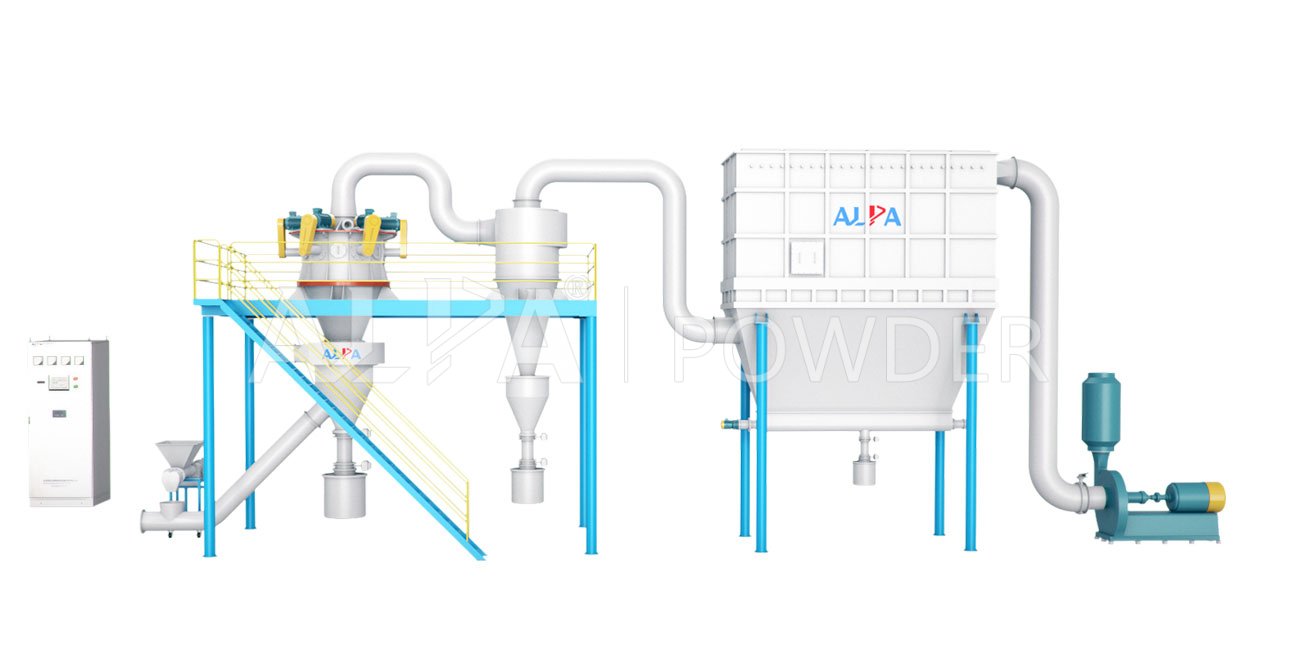

Working Principle:

the classifier and cyclone separator, dust collector and induced draft fan form a classifying system.

under the action of fan suction, the material is moved from the lower inlet of the classifier to the classifying zone with the ascending airflow. under the strong centrifugal force generated by the high-speed rotating turbine, the materials are separated and the fine particles which meet size requirements through the classifier impeller gap into the cyclone separator or the dust collector, the coarse particles entrained part of the fine particles collided with the wall and the velocity disappeared, descending along the cylinder wall to the secondary air outlet, and the coarse and fine particles were separated by the strong washing action of the secondary air. the fine particles rise to the classification zone for secondary classifying, and the coarse particles are lowered to the discharge port for discharging.

Q: What service do you supply?

A: 1). We offer consultancy for project feasibility assessment, process flow definition, preliminary layout and factory building plan, project budget, project time schedule, etc.

2). We supply sample processing tests in our test station where are equipped with our various machine products, to help clients compare performances of different types of machines or process.

3). We supply project engineering, automation engineering and civil engineering.

4). We send engineers to the clients' project site and offer on-site technical instruction and supervision during the machine installation, commissioning and test run.

Q:how can I trust on your quality?

A: 1). All of the machine be tested successfully in Weifang workshop before shipment.

2). We supply one year warranty for all equipment and lifelong after-sales service.

3). We can test your material in our equipment before place the order, to ensure our equipment is suitable for your project.

4). Our engineers will go to your factory to install and debug the equipment, they will not be back until these equipment can produce qualified products.

Q:Does your company provide Engineers Abroad Service?

A: Sure, we provide it. and we can provide free training for on-site workers.

Q:how to train our staff about operation and maintenance?

A: We will provide detailed technical instructive pictures to teach them for the operation and maintenance. In addition, our engineers for guide assembly will teach your staff on site.