| After-sales Service Provided: | Engineers available to service machinery overseas |

|---|---|

| Certification: | CE, ISO |

| Brand Name: | ALPA |

| Type: | Spiral Jet Mill |

| Condition: | New |

| Warranty: | 1-year |

| Weight: | 300kg |

| Dimension(L*W*H): | 1*1*1 |

| Power(W): | 26kw |

| Voltage: | Local |

| Model Number: | MQP |

| Place of Origin: | China (Mainland) |

| Product Type: | |

| Feed Size (mm): | <5 |

| Product Size (d97:um): | 8-150 |

| Production Capacity (kg/h): | 5-6000 |

| Air Pressure (Mpa): | 0.7-0.85 |

Quick Details

Specifications

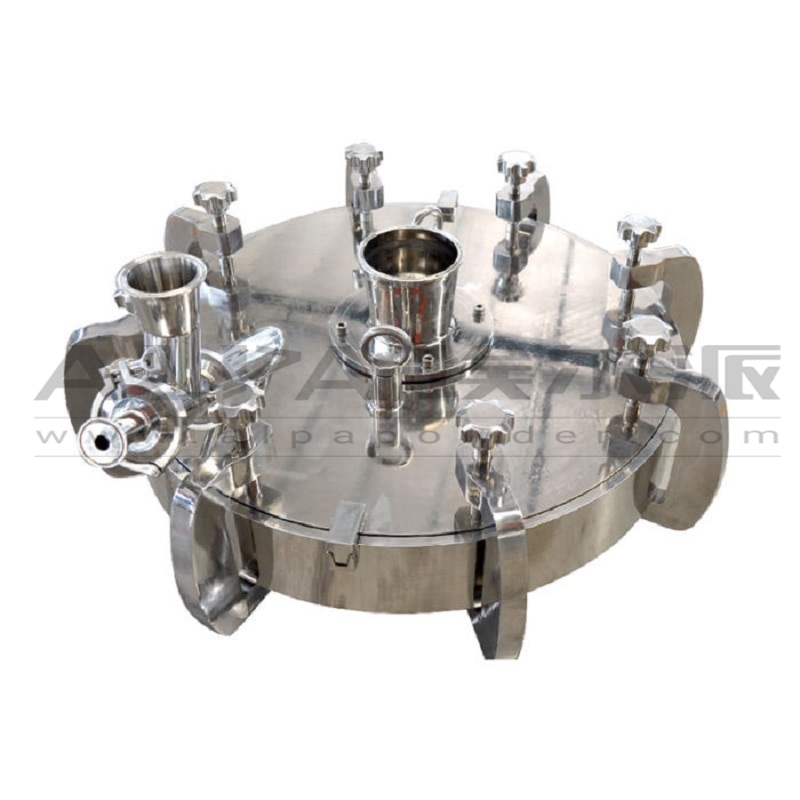

Silver Powder Ultrafine Grinding Spiral Jet Mill Disc Micronizer

Spiral Jet Mill Applications:

Spiral Jet Mill Advantages:

1.Available particle size D50:1.5-45μm, mostly suitable for depolymerization.

2.Free of transmission parts, automatic classifying structure

3.the jet mill is suitable for dry grinding of various materials with Moh's hardness below 9, especially for the materials with high hardness, high purity and high added value

4.Constant temperature or low temperature, medium-free grinding,especially suitable for materials of heat sensitive, low melting point, sugary, volatile nature

5.the grinding process is completed by the collision of the materials themselves., Fully self-grinding, so The device is durable and the purity of products is high in contrast

6.Key parts like inner liner, classifying wheel and nozzle are made of ceramic such as aluminum oxide, zirconium oxide or silicon carbide, ensuring non-contact with metal throughout the grinding for high purity of the final product

Spiral Jet Mill Applications:

Widely used in chemical, pharmaceutical, cosmetics, intermediates, food and other industries.

1.Available particle size D50:1.5-45μm, mostly suitable for depolymerization.

2.Free of transmission parts, automatic classifying structure

3.the jet mill is suitable for dry grinding of various materials with Moh's hardness below 9, especially for the materials with high hardness, high purity and high added value

4.Constant temperature or low temperature, medium-free grinding,especially suitable for materials of heat sensitive, low melting point, sugary, volatile nature

5.the grinding process is completed by the collision of the materials themselves., Fully self-grinding, so The device is durable and the purity of products is high in contrast

6.Key parts like inner liner, classifying wheel and nozzle are made of ceramic such as aluminum oxide, zirconium oxide or silicon carbide, ensuring non-contact with metal throughout the grinding for high purity of the final product