| After-sales Service Provided: | Engineers available to service machinery overseas |

|---|---|

| Certification: | CE, ISO |

| Brand Name: | ALPA |

| Type: | Pulverizer |

| Condition: | New |

| Warranty: | 1-year |

| Weight: | 300kg |

| Dimension(L*W*H): | 1*1*1 |

| Power(W): | 26kw |

| Voltage: | Local |

| Model Number: | MQP |

| Place of Origin: | China (Mainland) |

| Product Type: | |

| Feed Size(mm): | <5 |

| Product Size(d97:um): | 8-150 |

| Production Capacity(kg/h): | 5-6000 |

| Air Pressure(Mpa): | 0.7-0.85 |

Quick Details

Specifications

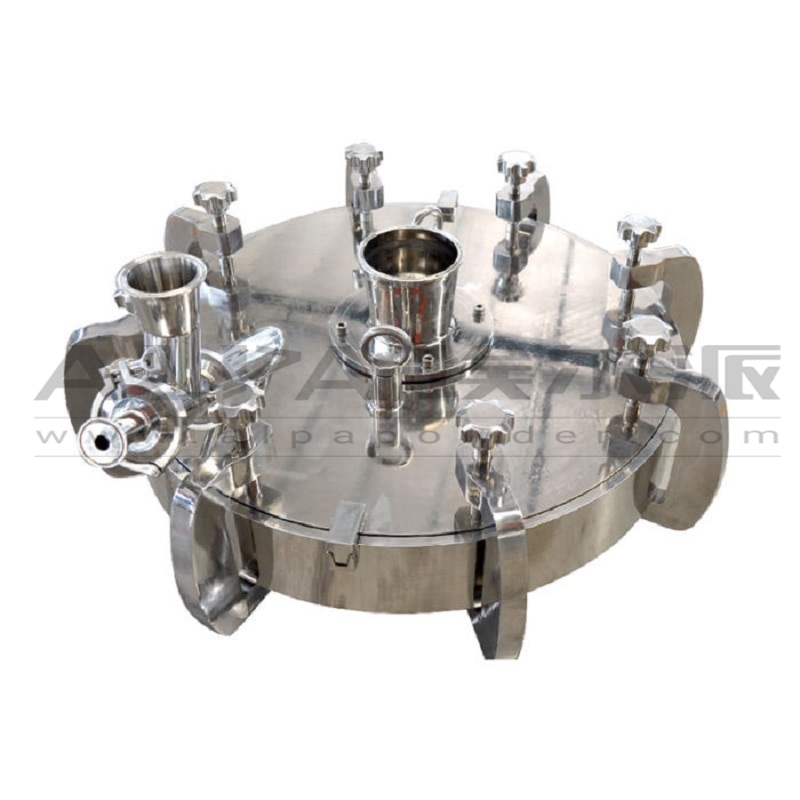

API Powder Pharmaceutical Spiral Jet Mill Micronization

Pharmaceutical Spiral Jet Mill Features:

1.Meet GMP/FDA requirements

2.Constant temperature or low temperature, medium-free grinding,especially suitable for materials of heat sensitive, low melting point, sugary, volatile nature

3.Key parts like inner liner, classifying wheel and nozzle are made of ceramic such as aluminum oxide, zirconium oxide or silicon carbide, ensuring non-contact with metal throughout the grinding for high purity of the final product

4.Grinding is in closed system, low dust and noise, clean and environmentally friendly production process

5.PLC control system, easy operation

6.Optional explosion-proof design, can also be upgraded to nitrogen circulation system to meet the ultra-fine grinding processing requirements of flammable and explosive oxide materials

Pharmaceutical Spiral Jet Mill Working Principle:

Pharmaceutical jet mill(Medical jet mill,Pharmacia jet mill,pharmacy jet mill) works with cyclone separator, dust collector and suction fan to form a complete grinding system. Compressed air flow after filtration and drying would go into milling chamber from nozzles, and meet in the center area, where material would be impacted and ground and sheared. Milled powder would go up to the classifying chamber by the air flow from suction fan. the high-speed rotation of classifier wheel would create a strong centrifugal force to separate coarse powder and fine powder. Qualified fine powder would go through the wheel vane then into the cyclone separator or dust collector, while mixture of coarse powder and fine powder would fall down to the milling chamber to be milled again.