| After-sales Service Provided: | Engineers available to service machinery overseas |

|---|---|

| Warranty: | 1year |

| Voltage: | AC380V |

| Brand Name: | HONGMING |

| Condition: | New |

| Weight: | 4200KG |

| Dimension(L*W*H): | 5500x4500x3300mm |

| Power(W): | 33Kw |

| Model Number: | HM-ZD350A |

| Place of Origin: | China (Mainland) |

| Processing Type: | Paper Folding Machine |

| Product Type: | |

| Model: | HM-ZD350A |

| Keyword: | rigid box making machine |

| Max.Length: | 350mm |

| Max.Width: | 250mm |

| Max.Height: | 120mm |

| Min.Length: | 60mm |

| Min.Width: | 50mm |

| Min.Height: | 10mm |

Quick Details

Specifications

HM-ZD350A Automatic Jewellery Box Making Machine

HM-ZD350A Automatic Jewellery Box Making MachineIs suitable to make various types of rigid boxes such as jewelry boxes, mobile phone boxes, gift boxes, cosmetic boxes, watch boxes, slanting box etc. Its maximum length 350mm and maximum width

250mm, Size range is bigger, more suitable for current packaging market. Machine's appearance is new design which

Is safer and more beautiful.

HM-ZD350A Automatic Jewellery Box Making Machine Adopts PLC and man-machine control, camera tracing system, and can automatically feed cover paper, feed greyboard, paste four corners, spot greyboard, lift box, fold corner edges and wrap box.

the feeder, the gluer and the conveyor are driven by servos, the machine has continuously variable transmission

and enjoys high accuracy, easy adjusting, and efficiency. the spotting unit adopts camera tracing system and robot

Arm to pick and spot the greyboard,enhancing the spotter accuracy to ± 0.05mm. the forming unit employs Japan

THK linear slider and virtual electronic cam driving system, guaranteeing the stable quality and fluent movement and

Enlarge the folding-in depth and corner edges.

Feature and functions:

1. Suit to all kinds of rigid boxes in mass production;

2. Parameters adopts computer digital setting;

3. Auto error stop and display;

4. Automatic feed paper and greyboard;

5. 24-hours control for glue pre-heating;

6. Wrapper can input 300 product formulas;

7. Corner pasting part with independent man-machine control

and heating system;

8. Adopt YASKAWA servo control system;

9. Spotter by camera tracing system and SCARA (Selective

Compliance Assembly Robot Arm) (spotting accuracy ±0.05mm);

10. Wrapper can automatic lift and wrap box;

11. Automatic control system for glue viscosity (optional).

12. Digital setting with memory system(optional).

NOTE

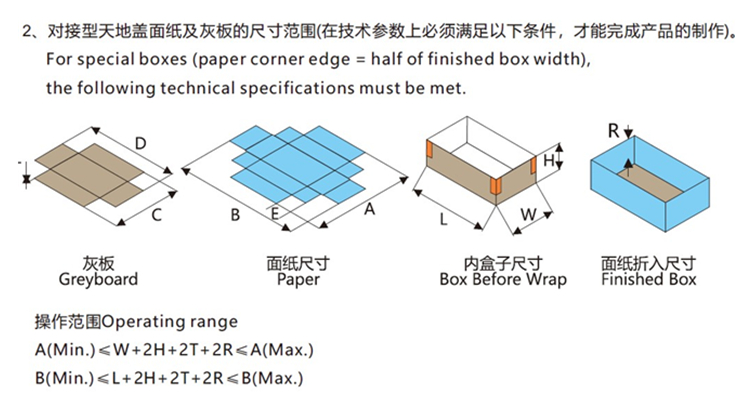

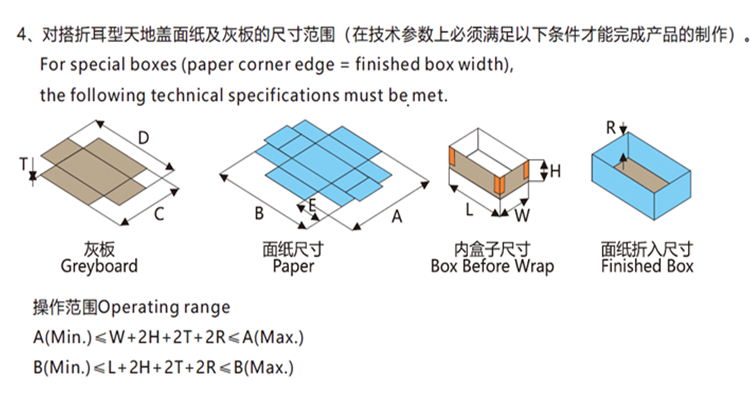

1, the finished Box Max sizes are determined by paper size.

A(Min.)≤W+2H+2T+2R≤A(Max.); B(Min.)≤L+2H+2T+2R≤B(Max.)

2, Either the Max. Sizes or the Min. Sizes can not be fulfilled on the same box.

3, the production speed of the rigid box machine is determined by the box size, the paper and the greyboard materials.

4, Seller doesn't provide air compressor. (8atm=0.808MPa, 7.5kW compressor is needed)

5, Item 5 is optional device for HM-ZD350A &HM-ZD350J.

HM-ZD350A Automatic Jewellery Box Making MachineIs suitable to make various types of rigid boxes such as jewelry boxes, mobile phone boxes, gift boxes, cosmetic boxes, watch boxes, slanting box etc. Its maximum length 350mm and maximum width

250mm, Size range is bigger, more suitable for current packaging market. Machine's appearance is new design which

Is safer and more beautiful.

HM-ZD350A Automatic Jewellery Box Making Machine Adopts PLC and man-machine control, camera tracing system, and can automatically feed cover paper, feed greyboard, paste four corners, spot greyboard, lift box, fold corner edges and wrap box.

the feeder, the gluer and the conveyor are driven by servos, the machine has continuously variable transmission

and enjoys high accuracy, easy adjusting, and efficiency. the spotting unit adopts camera tracing system and robot

Arm to pick and spot the greyboard,enhancing the spotter accuracy to ± 0.05mm. the forming unit employs Japan

THK linear slider and virtual electronic cam driving system, guaranteeing the stable quality and fluent movement and

Enlarge the folding-in depth and corner edges.

Feature and functions:

1. Suit to all kinds of rigid boxes in mass production;

2. Parameters adopts computer digital setting;

3. Auto error stop and display;

4. Automatic feed paper and greyboard;

5. 24-hours control for glue pre-heating;

6. Wrapper can input 300 product formulas;

7. Corner pasting part with independent man-machine control

and heating system;

8. Adopt YASKAWA servo control system;

9. Spotter by camera tracing system and SCARA (Selective

Compliance Assembly Robot Arm) (spotting accuracy ±0.05mm);

10. Wrapper can automatic lift and wrap box;

11. Automatic control system for glue viscosity (optional).

12. Digital setting with memory system(optional).

NOTE

1, the finished Box Max sizes are determined by paper size.

A(Min.)≤W+2H+2T+2R≤A(Max.); B(Min.)≤L+2H+2T+2R≤B(Max.)

2, Either the Max. Sizes or the Min. Sizes can not be fulfilled on the same box.

3, the production speed of the rigid box machine is determined by the box size, the paper and the greyboard materials.

4, Seller doesn't provide air compressor. (8atm=0.808MPa, 7.5kW compressor is needed)

5, Item 5 is optional device for HM-ZD350A &HM-ZD350J.