| Type: | hydraulic valve |

|---|---|

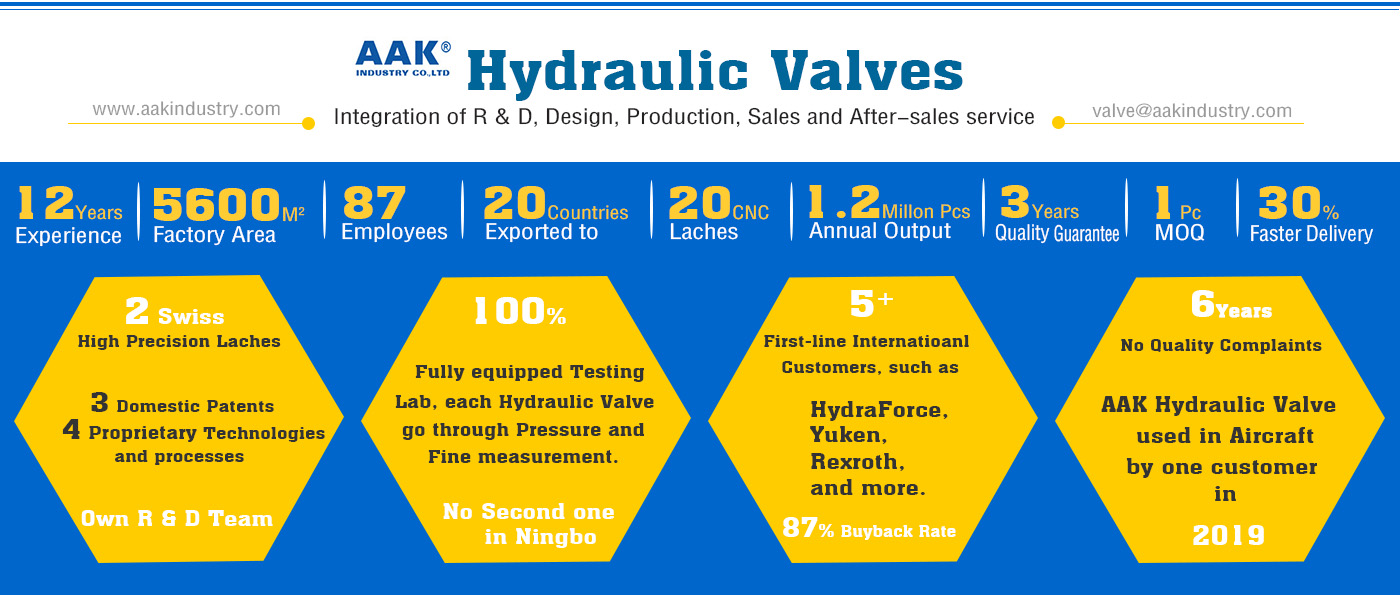

| Brand Name: | AAK hydraulic valve |

| Product name: | AAK |

| Color: | customized |

| Dies: | AAK |

Quick Details

Specifications

the spool of AAK hydraulic valve is made of high-grade tool steel with special heat treatment process. the hardness of the spool can reach 65HRC, which is even 7HRC higher than the 58HRC high-quality of the peers. Carson spent more than 2 months in making samples with 7 hydraulic valve factories. the hydraulic flow valves he got were all below 54HRC, while the hardness of AAK valve spool was 65hrc, which solved his urgent need.

at present, the hardness processing for precision parts from many hydraulic valve counterparts can not reach the high index. It seems to be qualified for domestic market, but far away from the high requirements of hydraulic valve products exported to overseas. First of all, these hydraulic valve factories do not have professional and systematic knowledge about how to choose the most suitable alloy steel material. Then, most importantly, the heat treatment is LED by the processing plant, because the heat treatment is outsourcing processing, and 20% of the factory changes the processing plant every time, so the hardness can not be guaranteed, not to mention stability. Because of these common faults in the industry, the spool of hydraulic valve shows the problems of easy deformation, fast wear and so on after being used for a period of time.

Carson, a new customer of hydraulic valves in the United States, left a message on our website at the end of 2020. We have been in a continuous interaction, but never had the opportunity to cooperate. Last month, he has an order for a hydraulic flow valve. His customer had a specific requirement of 64HRC for the hardness of the valve spool. He spent more than 2 months with 7 suppliers to make samples, but the hardness of the spool of the hydraulic flow valve still couldn't pass the test. these suppliers of hydraulic flow valve adjusted the material for many times, but the hardness of the valve spool could not meet the standard.

with the delivery date approaching, Carson was very worried. He asked us by email if we could make a hydraulic flow valve, and the specific hardness requirement of the valve spool is 64HRC. with so many years of experience in hydraulic valve export, AAK is more and more strict in controlling every detail. Especially in the processing of valve spool, the technology is becoming more and more mature.

for the material selection of the valve spool, we need to select the most suitable steel according to the use scene of the hydraulic valve, the medium used, and the customer's hydraulic parameters, combined with the wear resistance, linear expansion coefficient, deformation of different steels. the high grade tool steels like Cr12MoV, 12CrNi3A, 18crniwa and GCr15 are what we commonly choose.

in the hardness control of the valve spool of the hydraulic flow valve, the last and most important step is the heat treatment process of steel. If the hardness needs to be above 64HRC, the carbon content of steel should be considered first, and then find a way in heat treatment. Steels with different contents need different heat treatment methods in quenching, carburizing and nitriding. Pretreatment, quenching, cold treatment, tempering, aging, fine processing, secondary aging, aging temperature and holding time of these processes are the key. We can achieve the aging temperature of 420 ℃ and heat preservation for more than 10h, and we can obtain hardness of 65HRC or more, which is beyond the imagination and ability of our peers.

after 15 days of design and proofing, AAK successfully sent the hydraulic flow control valve to Carson. Within 7 days after receiving the flow hydraulic valve sample, he placed an order of 1 million hydraulic flow control valves with AAK, because the spool hardness of our hydraulic flow valve sample reaches 65HRC.

AAK Hydraulic Valve is able to solve the urgent needs of new and old customers, because of the picky attitude on technology of all AAK staff. Welcome to try an order!

at present, the hardness processing for precision parts from many hydraulic valve counterparts can not reach the high index. It seems to be qualified for domestic market, but far away from the high requirements of hydraulic valve products exported to overseas. First of all, these hydraulic valve factories do not have professional and systematic knowledge about how to choose the most suitable alloy steel material. Then, most importantly, the heat treatment is LED by the processing plant, because the heat treatment is outsourcing processing, and 20% of the factory changes the processing plant every time, so the hardness can not be guaranteed, not to mention stability. Because of these common faults in the industry, the spool of hydraulic valve shows the problems of easy deformation, fast wear and so on after being used for a period of time.

Carson, a new customer of hydraulic valves in the United States, left a message on our website at the end of 2020. We have been in a continuous interaction, but never had the opportunity to cooperate. Last month, he has an order for a hydraulic flow valve. His customer had a specific requirement of 64HRC for the hardness of the valve spool. He spent more than 2 months with 7 suppliers to make samples, but the hardness of the spool of the hydraulic flow valve still couldn't pass the test. these suppliers of hydraulic flow valve adjusted the material for many times, but the hardness of the valve spool could not meet the standard.

with the delivery date approaching, Carson was very worried. He asked us by email if we could make a hydraulic flow valve, and the specific hardness requirement of the valve spool is 64HRC. with so many years of experience in hydraulic valve export, AAK is more and more strict in controlling every detail. Especially in the processing of valve spool, the technology is becoming more and more mature.

for the material selection of the valve spool, we need to select the most suitable steel according to the use scene of the hydraulic valve, the medium used, and the customer's hydraulic parameters, combined with the wear resistance, linear expansion coefficient, deformation of different steels. the high grade tool steels like Cr12MoV, 12CrNi3A, 18crniwa and GCr15 are what we commonly choose.

in the hardness control of the valve spool of the hydraulic flow valve, the last and most important step is the heat treatment process of steel. If the hardness needs to be above 64HRC, the carbon content of steel should be considered first, and then find a way in heat treatment. Steels with different contents need different heat treatment methods in quenching, carburizing and nitriding. Pretreatment, quenching, cold treatment, tempering, aging, fine processing, secondary aging, aging temperature and holding time of these processes are the key. We can achieve the aging temperature of 420 ℃ and heat preservation for more than 10h, and we can obtain hardness of 65HRC or more, which is beyond the imagination and ability of our peers.

after 15 days of design and proofing, AAK successfully sent the hydraulic flow control valve to Carson. Within 7 days after receiving the flow hydraulic valve sample, he placed an order of 1 million hydraulic flow control valves with AAK, because the spool hardness of our hydraulic flow valve sample reaches 65HRC.

AAK Hydraulic Valve is able to solve the urgent needs of new and old customers, because of the picky attitude on technology of all AAK staff. Welcome to try an order!