| After-sales Service Provided: | Engineers available to service machinery overseas |

|---|---|

| Warranty: | one year |

| Certification: | ISO |

| Brand Name: | Wonlean |

| Condition: | New |

| Rated Power: | 37kw |

| Voltage: | 420MPA |

| Place of Origin: | Christmas Island |

| Machine Cover: | Stainless Steel |

| Main Motor: | SIEMENS Motor |

| Servo Motor: | Yaskawa |

| Structure: | Oil immersion |

| Intensifier: | ACCUSTREAM |

| Rail Screw: | HIWIN |

| PLC: | OMRON |

| Cutting accuracy: | 0.1mm |

| Control precision: | 0.1mm |

| Repeat accuracy: | 0.05mm |

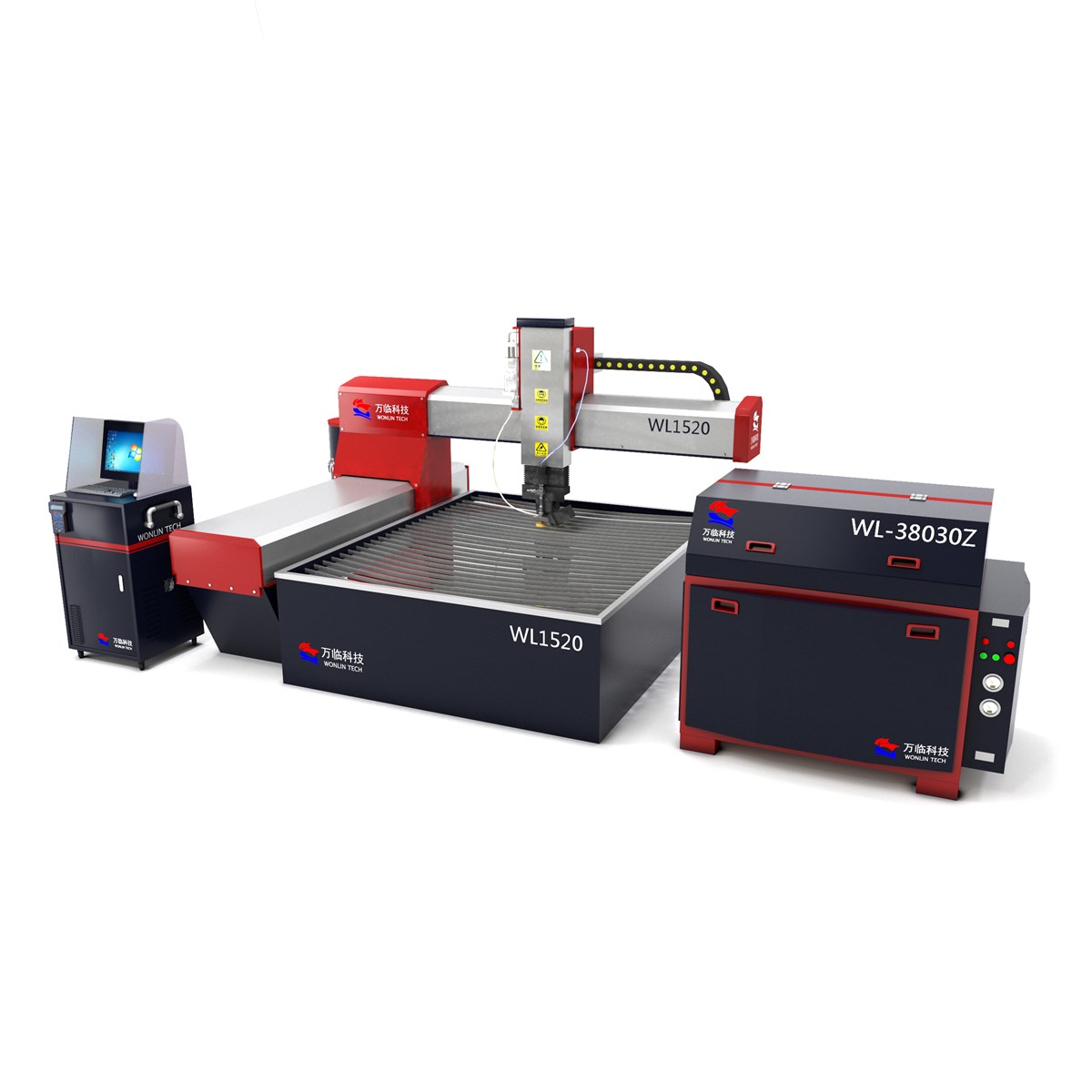

Quick Details

Specifications

Product Description

Application and advantages of waterjet cutting:

Waterjet Cutting MachineIs an effective tool for any shape of artistic creation. the traditional cutting method is saw cutting only in a row. When cutting the curves, the model should be made according to the size and then polished.Waterjet Cutting MachineCan cut any shape of models under the control of the CNC program.

1. Smooth cutting quality is good.

2.the cutting accuracy ofWaterjet cutterIs up to 0.1mm. Edge joints are regular, andWater jet cuttingCan also make very complex puzzles and murals.

3. Cutting speed is fast, and product consistency and interchangeability are very good.

4. Drilling, cutting and forming can be done at once.

5. Improve the working environment and reduce the impact of dust and noise on the operator.

6.Waterjet cuttingIs a cold cutting that does not damage the internal structure of the cutting material.

7. It is the only processing machine for composite materials and fragile porcelain.

8. WAterjet Cutter Can cut metal, rubber, foam, plastic, composite materials, stone, ceramic tile, marble, glass, etc.

Product Advantage:

1)Cutting accuracy is up to 0.1mm.

2)the main core of Intensifier is made in USA".

3)the guide screw is different from the traditional dry structure. the linear guide rail and ball screw are immersed in the oil tank with oil-immersed structure, which can fully lubricate the guide screw and further isolate the abrasion caused by the contamination of the guide screw so as to protect the cutting accuracy.

4)the high-power servo motor and the guide screw are connected directly by flexible coupling, which eliminates the gap of traditional belt connection and improves the cutting precision.