| Chemical Composition: | C |

|---|---|

| Dimensions: | customized |

| Application: | customized |

| Brand Name: | NINGHEDA |

| color: | black gray |

| Model Number: | NX603 |

| Place of Origin: | China (Mainland) |

| density: | 1.8-1.9 |

| name: | Graphite Heating Element |

| use: | Vacuum Sintering Furnace |

Quick Details

Specifications

Graphite heater / graphite heating elements are used frequently in high-temperature vacuum sintering furnaces and are also widely used. In high temperature furnaces, graphite parts can be used in vacuum sintering furnaces, graphitization furnaces, vacuum brazing furnaces, intermediate frequency vacuum induction furnaces, high temperature heat treatment furnaces, etc.

Advantages:

1.High strength.as the temperature rises, the graphite strength increases

2.High temperature resistance (graphite material melting point is 3850±50C)

3.Good heat shock resistance

4.Anti-oxidation

5.Strong corrosion resistance to acid and alkali liquid

6.Good conductivity and thermal efficiency.

7.Excellent chemical stability

8. High heat conductivity

9.Mechanical shock resistance

10.Small thermal expansion coefficient

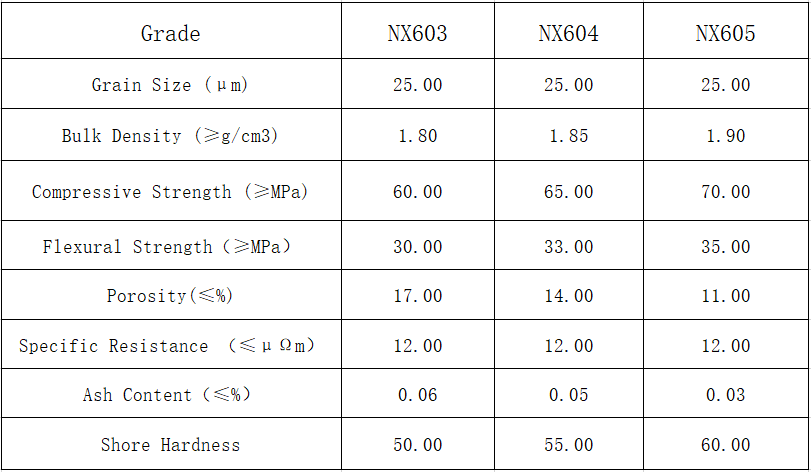

Technical Characteristic:

Advantages:

1.High strength.as the temperature rises, the graphite strength increases

2.High temperature resistance (graphite material melting point is 3850±50C)

3.Good heat shock resistance

4.Anti-oxidation

5.Strong corrosion resistance to acid and alkali liquid

6.Good conductivity and thermal efficiency.

7.Excellent chemical stability

8. High heat conductivity

9.Mechanical shock resistance

10.Small thermal expansion coefficient

Technical Characteristic: