| Brand Name: | SunHong |

|---|---|

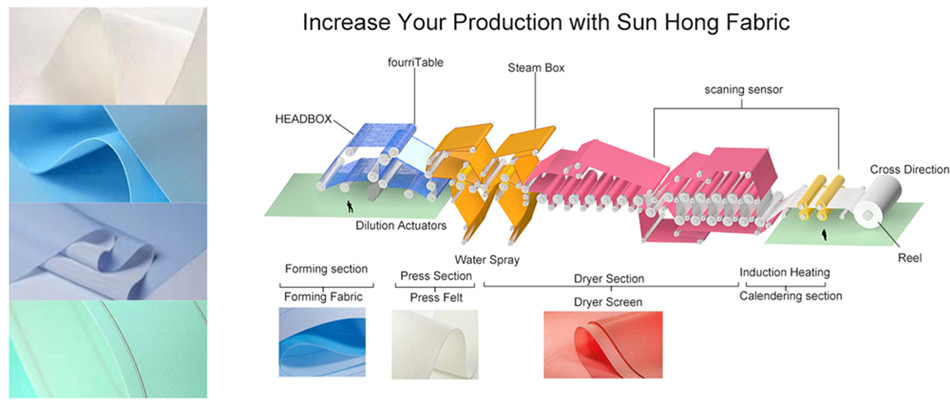

| application: | Paper forming and conveying |

| Yarn: | MD Yarn:0.18*6 CD Yarn:0.25*4 |

| Size: | made to order |

| Material: | Nylon |

| Model Number: | SH-PMF101 |

| Place of Origin: | China (Mainland) |

| Layer: | Single/Double/Triple |

| Speed: | Under 1500m/min |

Quick Details

Specifications

Paper making Felt Description

Paper making felt possess good air permeability, mark-less, heat resistance, wet resistance, anti-aging, structure stability, anti-worn out, dimensional stability, excellent tensile strength, high linear pressure, easy to operate, long life performance.

According to paper machine and paper, we can change the structure of base mesh. It has the characters of anti-high pressure, good elasticity and filter ability, stable size, small elongation, great strength, effective to eliminate grooving, vacuum mark, blind-hole mark and other marks. Suitable to vacuum press, kinds of complex press and other press for producing high grad offset paper, and kinds of high grade paper and paper board etc.

Type

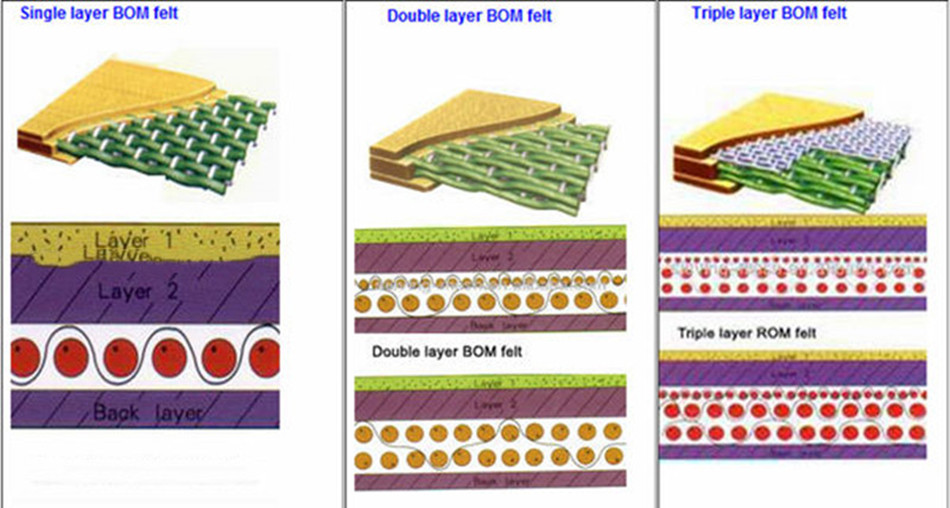

Single Layer paper machine felt is made up of single base layer fabric and fiber layer. Base layer is woven from synthetic filament or multi-filament. The structure is designed base on different paper machine, different press position and different type of paper.

Double Layer paper machine felt includes 1+1 composite structure and double layer of MD yarn structure. 1+1 composite structure BOM is consisted of two different thickness of base material. both of these base materials can be changed to different construction and sizes to suit the requirement of different paper machines.

Triple layer Paper machine felt includes 1 +2, 2 +1 and 1 +1 +1 composite BOM felt.

Applying to high speed of the paper machine for suction complex press, large diameter nip roll press and shoe press and can produce high-grade newsprint, write paper, paperboard etc.

Function

1.Water filtering function:as a dehydration medium, when the paper sheet is dehydrated in the vacuum box and press area, the paper blanket absorbs and filters out the water from the paper sheet.

2. Leveling effect:In the process of web transfer and dehydration, it can smooth and modify the paper surface.

3. Function of conveyor belt:the paper is transferred from the net part to the drying shaft through the pressing part, and the passive roller and net cage are driven to run.

Application

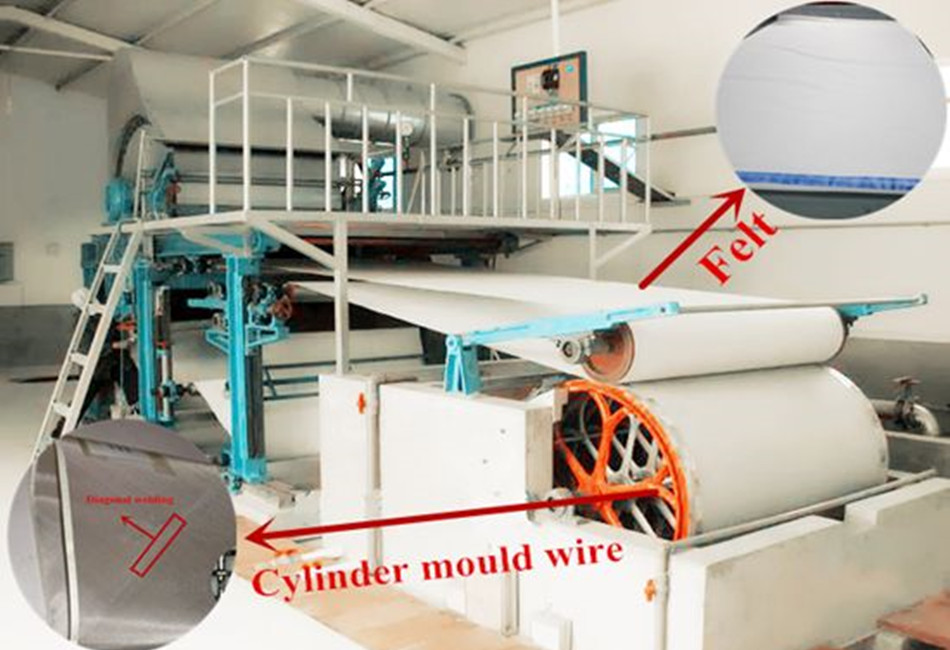

Paper Making Felt refers to the fabric felt used in paper forming and conveying in paper industry. According to the position on the paper machine, it can be divided into wet felt, upper felt and dry felt.

Paper machine: cylinder,super forming,foudrinier,inclined wire machine,nip wire machine etc for forming section felt,press felt.

Machine Velocity:≤800m/min Paper:≥8g/m2 kinds of paper. NIP:≤80kn/m.

Packing & Delivery

1.Bubble Film and waste thick fabric wrapping while protecting inside fabric.

2.Wrapped special fabric package outside(Air shipping).

3.Composite wooden box(sea shipping).

about US

Sun Hong Group was established in 2010,we supply main contractor for paper machine clothing, from forming fabric to press felt and to dryer fabrics. Press felt is our core strategy products.We select advanced Texo weaving looms, wide Carding lines, the widest Fehrer needle loom and the best raw material to make press felt. We can able to make Press Felts 8-100 meters in length, and up to 8 meters in width, and make different size and weight according to the customer needs.

Forming fabric and dryer fabric are also our advantage products,we will provide technical support for customers to help them choose suitable products. Our fabrics produced with imported equipment 14m German Weaving machine. Wide weaving width makes sure the rate of finished products yields. Austria Automatic seaming machine obtains Average splice point and strong constructions and Norway 14.5m heat-setting machine.

Paper making felt possess good air permeability, mark-less, heat resistance, wet resistance, anti-aging, structure stability, anti-worn out, dimensional stability, excellent tensile strength, high linear pressure, easy to operate, long life performance.

According to paper machine and paper, we can change the structure of base mesh. It has the characters of anti-high pressure, good elasticity and filter ability, stable size, small elongation, great strength, effective to eliminate grooving, vacuum mark, blind-hole mark and other marks. Suitable to vacuum press, kinds of complex press and other press for producing high grad offset paper, and kinds of high grade paper and paper board etc.

Type

Single Layer paper machine felt is made up of single base layer fabric and fiber layer. Base layer is woven from synthetic filament or multi-filament. The structure is designed base on different paper machine, different press position and different type of paper.

Double Layer paper machine felt includes 1+1 composite structure and double layer of MD yarn structure. 1+1 composite structure BOM is consisted of two different thickness of base material. both of these base materials can be changed to different construction and sizes to suit the requirement of different paper machines.

Triple layer Paper machine felt includes 1 +2, 2 +1 and 1 +1 +1 composite BOM felt.

Applying to high speed of the paper machine for suction complex press, large diameter nip roll press and shoe press and can produce high-grade newsprint, write paper, paperboard etc.

Function

1.Water filtering function:as a dehydration medium, when the paper sheet is dehydrated in the vacuum box and press area, the paper blanket absorbs and filters out the water from the paper sheet.

2. Leveling effect:In the process of web transfer and dehydration, it can smooth and modify the paper surface.

3. Function of conveyor belt:the paper is transferred from the net part to the drying shaft through the pressing part, and the passive roller and net cage are driven to run.

Application

Paper Making Felt refers to the fabric felt used in paper forming and conveying in paper industry. According to the position on the paper machine, it can be divided into wet felt, upper felt and dry felt.

Paper machine: cylinder,super forming,foudrinier,inclined wire machine,nip wire machine etc for forming section felt,press felt.

Machine Velocity:≤800m/min Paper:≥8g/m2 kinds of paper. NIP:≤80kn/m.

Packing & Delivery

1.Bubble Film and waste thick fabric wrapping while protecting inside fabric.

2.Wrapped special fabric package outside(Air shipping).

3.Composite wooden box(sea shipping).

about US

Sun Hong Group was established in 2010,we supply main contractor for paper machine clothing, from forming fabric to press felt and to dryer fabrics. Press felt is our core strategy products.We select advanced Texo weaving looms, wide Carding lines, the widest Fehrer needle loom and the best raw material to make press felt. We can able to make Press Felts 8-100 meters in length, and up to 8 meters in width, and make different size and weight according to the customer needs.

Forming fabric and dryer fabric are also our advantage products,we will provide technical support for customers to help them choose suitable products. Our fabrics produced with imported equipment 14m German Weaving machine. Wide weaving width makes sure the rate of finished products yields. Austria Automatic seaming machine obtains Average splice point and strong constructions and Norway 14.5m heat-setting machine.