| Brand Name: | SunHong |

|---|---|

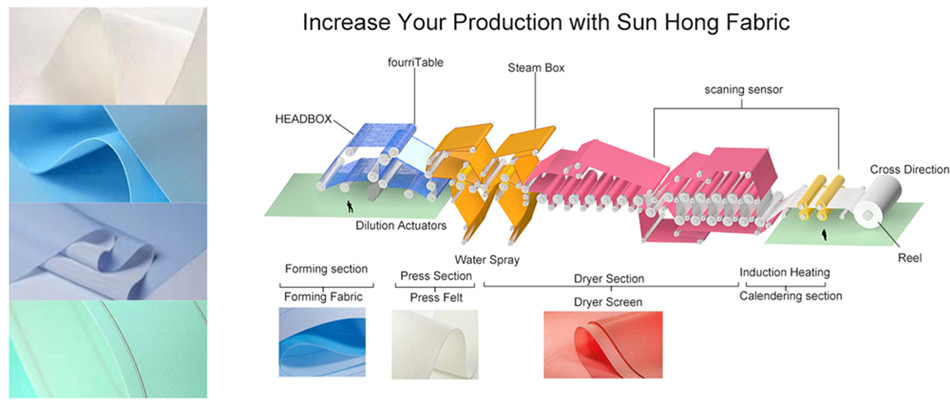

| application: | Paper forming and conveying |

| Yarn: | MD Yarn:0.18*6 CD Yarn:0.25*4 |

| Size: | made to order |

| Material: | Nylon |

| Model Number: | SH-PMF101 |

| Place of Origin: | China (Mainland) |

| Layer: | Single/Double/Triple |

| Speed: | Under 1500m/min |

Quick Details

Specifications

Press Felt Description

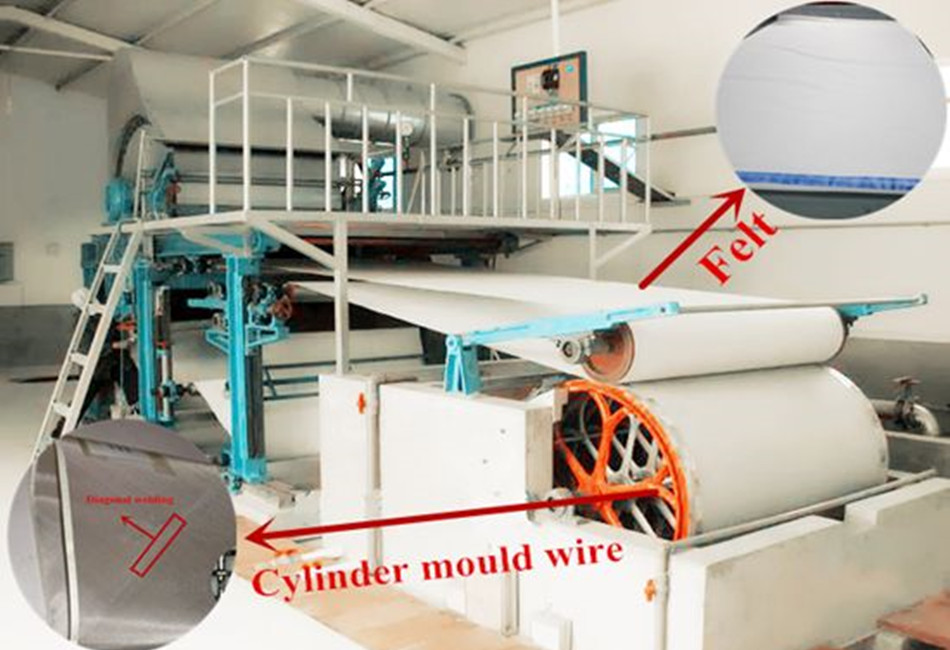

Felt is an impOrtant pAper machine spare part and is widely used in all kinds of paper making machine, such as toilet paper machine, tissue paper making machine, wet napkin making machine, a3,a4 paper making machine, kraft paper machine and corrugated paper making machine. In drying section, wire section and reeling end of paper machine, felt are an necessary part to ensure the machine to function well.

Type

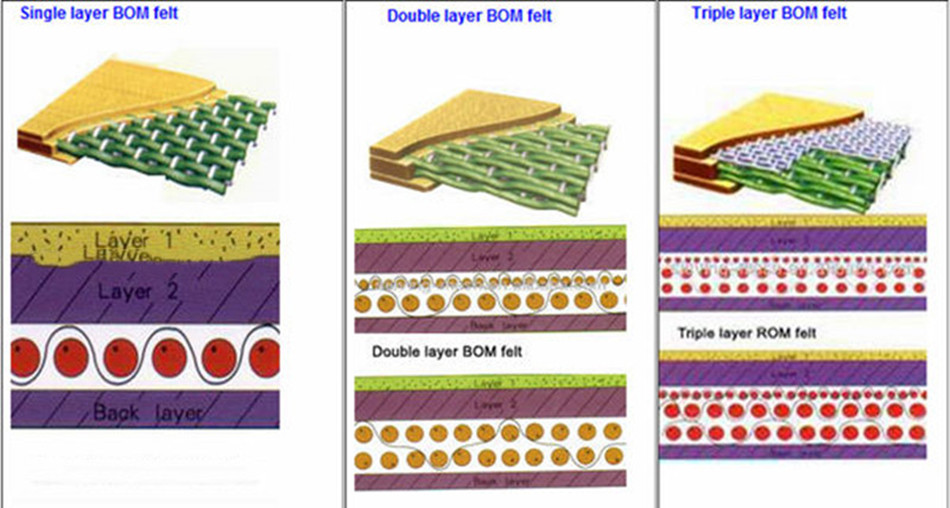

Single Layer paper machine felt is made up of single base layer fabric and fiber layer. Base layer is woven from synthetic filament or multi-filament. The structure is designed base on different paper machine, different press position and different type of paper.

Double Layer paper machine felt includes 1+1 composite structure and double layer of MD yarn structure. 1+1 composite structure BOM is consisted of two different thickness of base material. both of these base materials can be changed to different construction and sizes to suit the requirement of different paper machines.

Triple layer Paper machine felt includes 1 +2, 2 +1 and 1 +1 +1 composite BOM felt.

Applying to high speed of the paper machine for suction complex press, large diameter nip roll press and shoe press and can produce high-grade newsprint, write paper, paperboard etc.

Advantages

Paper making felt posSess good air permeability, mark-less, heat resistance, wet resistance, anti-aging, structure stability, anti-worn out, dimensional stability, excellent tensile strength, high linear pressure, easy to operate, long life performance.

Function

1.Water filtering function:as a dehydration medium, when the paper sheet is dehydrated in the vacuum box and press area, the paper blanket absorbs and filters out the water from the paper sheet.

2. Leveling effect:In the process of web transfer and dehydration, it can smooth and modify the paper surface.

3. Function of conveyor belt:the paper is transferred from the net part to the drying shaft through the pressing part, and the passive roller and net cage are driven to run.

Detail photos

Detail photos

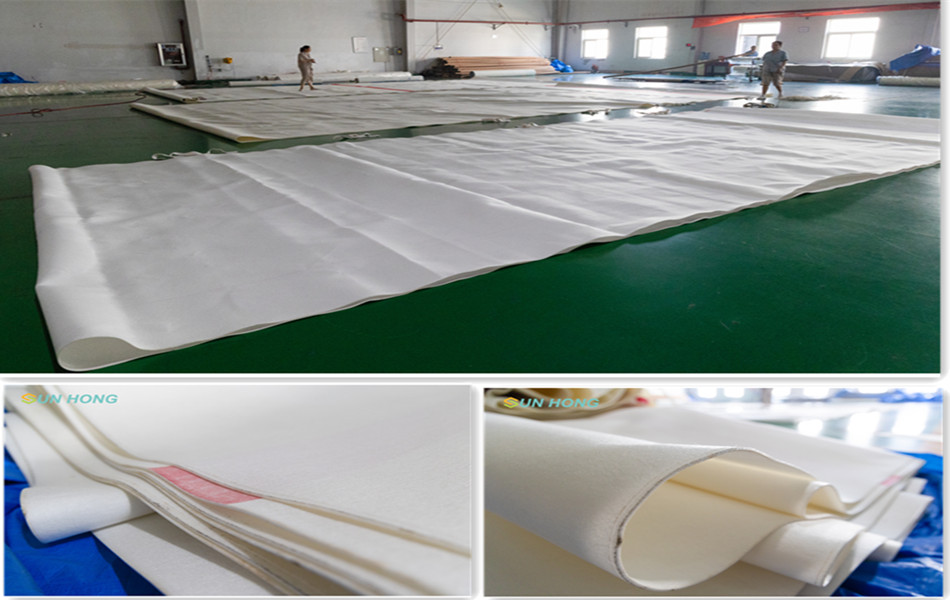

Packing & Shipping

1.Bubble Film and waste thick fabric wrapping while protecting inside fabric.

2.Wrapped special fabric package outside(Air shipping).

3.Composite wooden box(seashipping).

Felt is an impOrtant pAper machine spare part and is widely used in all kinds of paper making machine, such as toilet paper machine, tissue paper making machine, wet napkin making machine, a3,a4 paper making machine, kraft paper machine and corrugated paper making machine. In drying section, wire section and reeling end of paper machine, felt are an necessary part to ensure the machine to function well.

Type

Single Layer paper machine felt is made up of single base layer fabric and fiber layer. Base layer is woven from synthetic filament or multi-filament. The structure is designed base on different paper machine, different press position and different type of paper.

Double Layer paper machine felt includes 1+1 composite structure and double layer of MD yarn structure. 1+1 composite structure BOM is consisted of two different thickness of base material. both of these base materials can be changed to different construction and sizes to suit the requirement of different paper machines.

Triple layer Paper machine felt includes 1 +2, 2 +1 and 1 +1 +1 composite BOM felt.

Applying to high speed of the paper machine for suction complex press, large diameter nip roll press and shoe press and can produce high-grade newsprint, write paper, paperboard etc.

Advantages

Paper making felt posSess good air permeability, mark-less, heat resistance, wet resistance, anti-aging, structure stability, anti-worn out, dimensional stability, excellent tensile strength, high linear pressure, easy to operate, long life performance.

Function

1.Water filtering function:as a dehydration medium, when the paper sheet is dehydrated in the vacuum box and press area, the paper blanket absorbs and filters out the water from the paper sheet.

2. Leveling effect:In the process of web transfer and dehydration, it can smooth and modify the paper surface.

3. Function of conveyor belt:the paper is transferred from the net part to the drying shaft through the pressing part, and the passive roller and net cage are driven to run.

Packing & Shipping

1.Bubble Film and waste thick fabric wrapping while protecting inside fabric.

2.Wrapped special fabric package outside(Air shipping).

3.Composite wooden box(seashipping).