| Brand Name: | Ruishi |

|---|---|

| Refractoriness (Degree): | 1770°< Refractoriness< 2000° |

| Al2O3 Content (%): | >95 |

| Material: | abrasive bauxite |

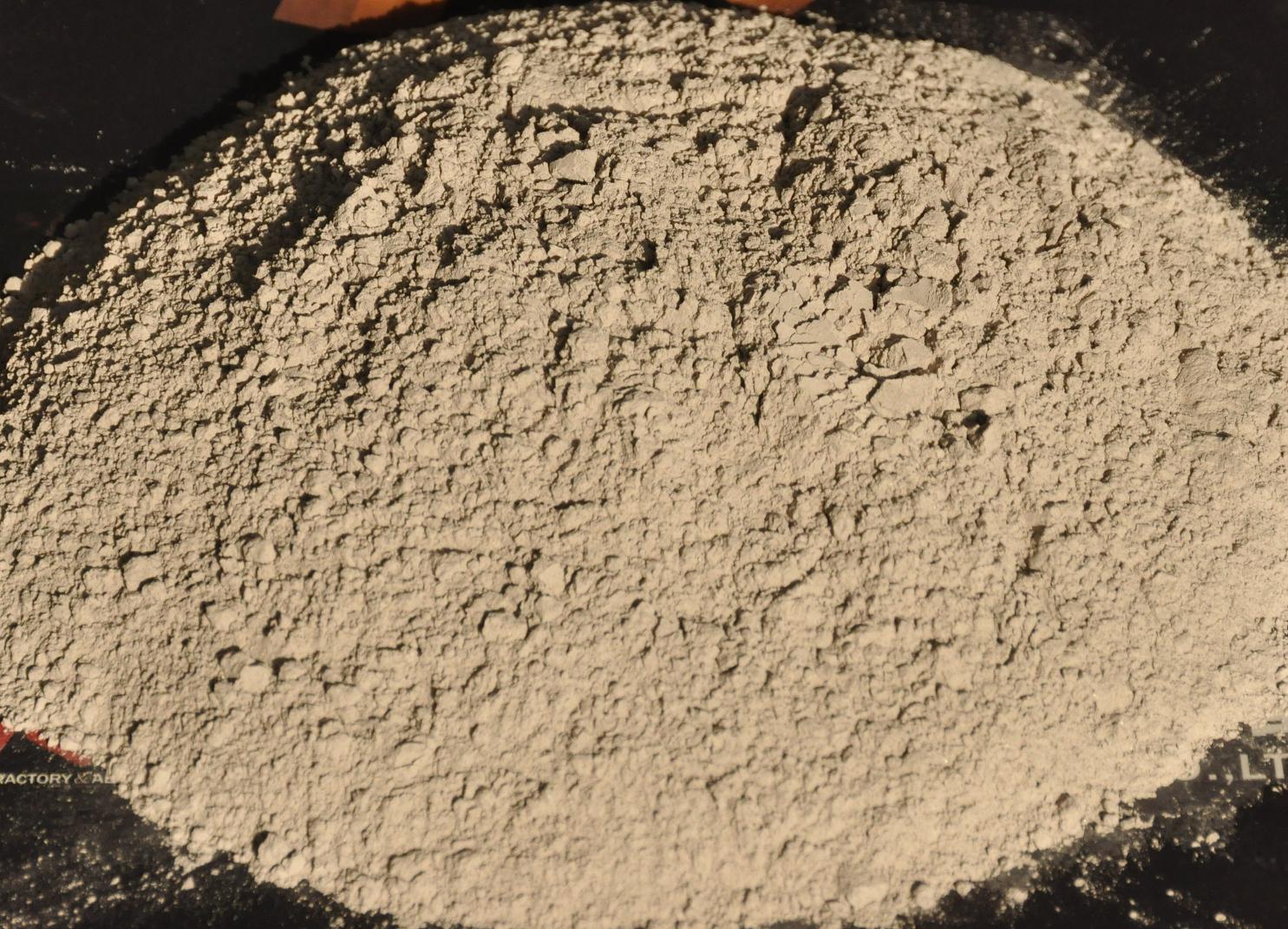

| Shape: | Powder |

Quick Details

Specifications

Brown corundum is made of high-quality abrasive-grade bauxite with auxiliary materials, and is refined in an electric arc furnace at a high temperature above 2250 °C.

the RS brown corundum produced by our company has the characteristics of high purity, good crystallization, strong fluidity, low coefficient of linear expansion and corrosion resistance. the product has the characteristics of no explosion, no pulverization and no cracking during the application process, and is often used in the abrasives and refractory raw material industries.

the smelting method of brown corundum can be divided into: dumping furnace and fixed furnace.

the main products are: brown corundum Barmac sand, roller sand, ball grinding sand, segment sand, P sand, fine powder, micro powder.

Special treatment products are: high temperature calcined brown corundum, medium temperature calcined brown corundum, water washing, pickling, dry cleaning (air washing).

Scope of application

Abrasives: grinding wheel, abrasive belt, sandpaper, abrasive cloth, cutting disc, sandblasting process, grinding, wear-resistant floor, water jet cutting, coated abrasive, bonded abrasive, etc.

Refractory materials: castable, refractory brick, ramming material, slide plate, nozzle, ladle, furnace lining, precision casting, etc.

Ruishi brand brown corundum physical and chemical indicators:

Application Specifications Main Chemical Composition % Magnetic Matter %

Al2O3 Fe2O3 SiO2 TiO2

Abrasives F 4#80# ≥95 ≤0.3 ≤1.5 ≤3.0 ≤0.05

90#150# ≥94 ≤0.03

180#240# ≥93 ≤0.3 ≤1.5 ≤3.5 ≤0.02

P 8#80# ≥95.0 ≤0.2 ≤1.2 ≤3.0 ≤0.05

100#150# ≥94.0 ≤0.03

180#220# ≥93.0 ≤0.3 ≤1.5 ≤3.5 ≤0.02

W 1#-63# ≥92.5 ≤0.5 ≤1.8 ≤4.0

Refractory segment sand 0-1mm

1-3mm

3-5mm

5-8mm

8-12mm ≥95 ≤0.3 ≤1.5 ≤3.0

25-0mm

10-0mm

50-0mm

30-0mm ≥95 ≤0.3 ≤1.5 ≤3.0

Fine powder 180#-0

200#-0

320#-0 ≥94.5 ≥93.5 ≤0.5 ≤1.5 ≤3.5

Note: F is the specification for bonded abrasives and sandblasting

P is the specification for coated abrasives

W is micro powder, 320# is W40

Physical properties of brown corundum:

Project Indicator

Color dark brown (dark blue after calcination)

Crystal form Trigonal system

Hardness (Mohs) ≥9.0

Melting point (℃) 2250

Maximum operating temperature (℃) 1900

True density (g/cm3) ≥3.90

Linear expansion coefficient (01600℃) 79

Model

Grit No. Bulk Density

Bluck density model

Grit No. Bulk Density

Bluck density model

Grit No. Bulk Density

Bluck density

F12 2.02-2.10 F40 1.81-1.89 F120 1.61-1.69

F14 2.00-2.08 F46 1.79-1.87 F150 1.59-1.67

F16 1.97-2.05 F54 1.77-1.85 F180 1.57-1.67

F20 1.94-2.02 F60 1.76-1.84 F220 1.55-1.63

F22 1.92-2.00 F70 1.75-1.83

F24 1.90-1.98 F80 1.73-1.81

F30 1.88-1.96 F90 1.71-1.79

F36 1.87-1.95 F100 1.64-1.72

the RS brown corundum produced by our company has the characteristics of high purity, good crystallization, strong fluidity, low coefficient of linear expansion and corrosion resistance. the product has the characteristics of no explosion, no pulverization and no cracking during the application process, and is often used in the abrasives and refractory raw material industries.

the smelting method of brown corundum can be divided into: dumping furnace and fixed furnace.

the main products are: brown corundum Barmac sand, roller sand, ball grinding sand, segment sand, P sand, fine powder, micro powder.

Special treatment products are: high temperature calcined brown corundum, medium temperature calcined brown corundum, water washing, pickling, dry cleaning (air washing).

Scope of application

Abrasives: grinding wheel, abrasive belt, sandpaper, abrasive cloth, cutting disc, sandblasting process, grinding, wear-resistant floor, water jet cutting, coated abrasive, bonded abrasive, etc.

Refractory materials: castable, refractory brick, ramming material, slide plate, nozzle, ladle, furnace lining, precision casting, etc.

Ruishi brand brown corundum physical and chemical indicators:

Application Specifications Main Chemical Composition % Magnetic Matter %

Al2O3 Fe2O3 SiO2 TiO2

Abrasives F 4#80# ≥95 ≤0.3 ≤1.5 ≤3.0 ≤0.05

90#150# ≥94 ≤0.03

180#240# ≥93 ≤0.3 ≤1.5 ≤3.5 ≤0.02

P 8#80# ≥95.0 ≤0.2 ≤1.2 ≤3.0 ≤0.05

100#150# ≥94.0 ≤0.03

180#220# ≥93.0 ≤0.3 ≤1.5 ≤3.5 ≤0.02

W 1#-63# ≥92.5 ≤0.5 ≤1.8 ≤4.0

Refractory segment sand 0-1mm

1-3mm

3-5mm

5-8mm

8-12mm ≥95 ≤0.3 ≤1.5 ≤3.0

25-0mm

10-0mm

50-0mm

30-0mm ≥95 ≤0.3 ≤1.5 ≤3.0

Fine powder 180#-0

200#-0

320#-0 ≥94.5 ≥93.5 ≤0.5 ≤1.5 ≤3.5

Note: F is the specification for bonded abrasives and sandblasting

P is the specification for coated abrasives

W is micro powder, 320# is W40

Physical properties of brown corundum:

Project Indicator

Color dark brown (dark blue after calcination)

Crystal form Trigonal system

Hardness (Mohs) ≥9.0

Melting point (℃) 2250

Maximum operating temperature (℃) 1900

True density (g/cm3) ≥3.90

Linear expansion coefficient (01600℃) 79

Model

Grit No. Bulk Density

Bluck density model

Grit No. Bulk Density

Bluck density model

Grit No. Bulk Density

Bluck density

F12 2.02-2.10 F40 1.81-1.89 F120 1.61-1.69

F14 2.00-2.08 F46 1.79-1.87 F150 1.59-1.67

F16 1.97-2.05 F54 1.77-1.85 F180 1.57-1.67

F20 1.94-2.02 F60 1.76-1.84 F220 1.55-1.63

F22 1.92-2.00 F70 1.75-1.83

F24 1.90-1.98 F80 1.73-1.81

F30 1.88-1.96 F90 1.71-1.79

F36 1.87-1.95 F100 1.64-1.72