| Grade: | / |

|---|---|

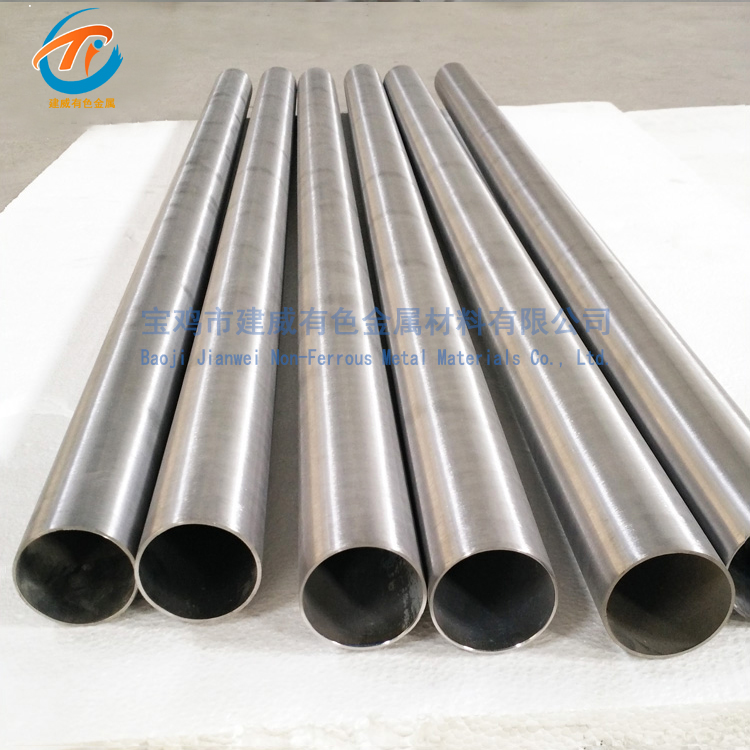

| Technique: | Seamless |

| Application: | / |

| Brand Name: | Jianwei |

| Shape: | / |

| Place of Origin: | China (Mainland) |

Quick Details

Specifications

Titanium tube light weight, high strength, superior mechanical properties. It is widely used in heat exchange equipment, such as tubular heat exchanger, coil heat exchanger, snake tube heat exchanger, condenser, evaporator and conveying pipeline. Many nuclear power industries use titanium tubes as standard for their units.

Titanium tube standard

GB/T3624-2010 industrial use of titanium and titanium alloy seamless tube standard

GB/T3625-2007 Titanium and titanium alloy tubes for heat exchangers and condensers

GB/T26058-2010 hot extruded titanium and titanium alloy seamless tube

American standard: ASTM 337 ASTM338

Titanium tube grades: TA1, TA2, TA3,TA8,TA9, TA10, BG1-00, BG1-0, Gr1, Gr2

among the three titanium alloys, the most commonly used are α titanium alloy and α+β titanium alloy; the cutting performance of α titanium alloy is the best, followed by α+β titanium alloy, and β titanium alloy is the worst. Α titanium alloy code for TA, β titanium alloy code for TB, α+β titanium alloy code for TC.

Titanium tube types: generally divided into two kinds, one is extruded called seamless titanium tube; One is the welding type called welding titanium tubes.

Types of titanium and titanium alloy tubes for heat exchangers and condensers Cold-rolled titanium and titanium alloy seamless tubes, welded titanium tubes, titanium and titanium alloy tubes produced by welding and rolling

Titanium seamless tube is divided into: cold rolled (cold drawing) method of production of titanium and titanium alloy seamless tube

Titanium and titanium alloy seamless tubes produced by extrusion

Titanium tube size: outer diameter * wall thickness * length

Characteristics of titanium tube:

1. Titanium pipe fittings have excellent corrosion resistance in many media;

2, titanium pipe fitting density is small, high strength, high temperature resistance;

3, the surface is clean, no dirt, dirt coefficient is greatly reduced.

Titanium tube standard

GB/T3624-2010 industrial use of titanium and titanium alloy seamless tube standard

GB/T3625-2007 Titanium and titanium alloy tubes for heat exchangers and condensers

GB/T26058-2010 hot extruded titanium and titanium alloy seamless tube

American standard: ASTM 337 ASTM338

Titanium tube grades: TA1, TA2, TA3,TA8,TA9, TA10, BG1-00, BG1-0, Gr1, Gr2

among the three titanium alloys, the most commonly used are α titanium alloy and α+β titanium alloy; the cutting performance of α titanium alloy is the best, followed by α+β titanium alloy, and β titanium alloy is the worst. Α titanium alloy code for TA, β titanium alloy code for TB, α+β titanium alloy code for TC.

Titanium tube types: generally divided into two kinds, one is extruded called seamless titanium tube; One is the welding type called welding titanium tubes.

Types of titanium and titanium alloy tubes for heat exchangers and condensers Cold-rolled titanium and titanium alloy seamless tubes, welded titanium tubes, titanium and titanium alloy tubes produced by welding and rolling

Titanium seamless tube is divided into: cold rolled (cold drawing) method of production of titanium and titanium alloy seamless tube

Titanium and titanium alloy seamless tubes produced by extrusion

Titanium tube size: outer diameter * wall thickness * length

Characteristics of titanium tube:

1. Titanium pipe fittings have excellent corrosion resistance in many media;

2, titanium pipe fitting density is small, high strength, high temperature resistance;

3, the surface is clean, no dirt, dirt coefficient is greatly reduced.